Quick formation method of titanium-based composite material having bionic shell structure

A titanium-based composite material and shell technology, which is applied in the directions of additive processing, process efficiency improvement, additive manufacturing, etc., to achieve the effect of broadening the scope of preparation and application, tight interlayer bonding, and breaking through weak interlayer bonding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

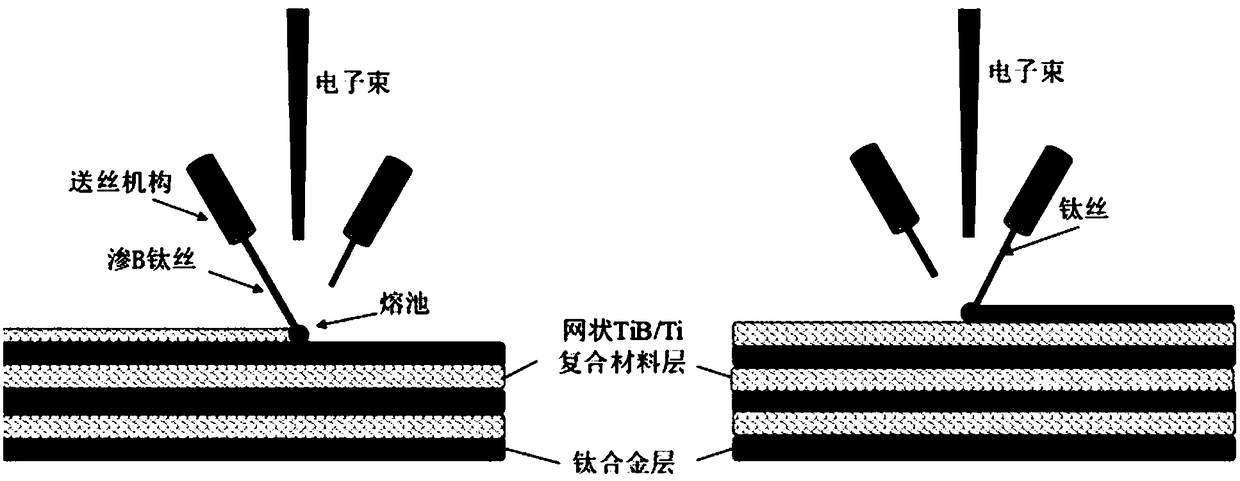

[0018] Using pure titanium wire and boronized pure titanium wire (0.5wt.% boron content) as raw materials, respectively put the titanium wire and boronized titanium wire into the wire feeding mechanism of the electron beam fuse forming equipment. Then adjust the wire feeding mechanism to ensure that the titanium wire intersects with the boronized titanium wire; then deflect the electron beam so that the beam spot of the electron beam coincides with the intersection point of the wire material to ensure that the wire material is accurately fed into the molten pool. Finally, through computer programming, boronized titanium wires and titanium wires are alternately deposited according to a predetermined path until the bionic shell structure titanium-based composite material is deposited. The specific process parameters of pure titanium wire electron beam fuse deposition process are: fuse current 12mA, voltage 60kV, travel speed 200mm / min, wire feeding speed 2r / min, vacuum degree bet...

Embodiment 2

[0020] The difference between this embodiment and Embodiment 1 is that the wire material is TC4 titanium wire and boronized titanium alloy wire (0.5 wt.% boron content). The specific process parameters of TC4 titanium wire electron beam fuse deposition process are: fuse current 13mA, voltage 60kV, travel speed 200mm / min, wire feeding speed 2r / min, vacuum degree better than 5×10 -2 Pa. The specific process parameters of the boronizing titanium alloy wire electron beam fuse deposition process are: fuse current 16mA, voltage 60kV, travel speed 200mm / min, wire feeding speed 2r / min, vacuum degree better than 5×10 -2 Pa. The tensile strength of the biomimetic shell structure titanium-based composite material with each layer thickness of 0.5mm is 933MPa, and the elongation is 11.3%.

Embodiment 3

[0022] The difference between this embodiment and Embodiment 1 is that the wire material is TC4 titanium wire and boronized titanium alloy wire (0.8 wt.% boron content). The specific process parameters of TC4 titanium wire electron beam fuse deposition process are: fuse current 14mA, voltage 60kV, travel speed 200mm / min, wire feeding speed 2r / min, vacuum degree better than 5×10 -2 Pa. The specific process parameters of boronizing titanium alloy wire electron beam fuse deposition process are: fuse current 18mA, voltage 60kV, travel speed 200mm / min, wire feeding speed 2r / min, vacuum degree better than 5×10 -2 Pa. The tensile strength of the biomimetic shell structure titanium-based composite material with each layer thickness of 0.5mm is 941MPa, and the elongation is 10.1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com