Corrosion resistant antistatic decorative deck plate and preparation method thereof

An antistatic and corrosion-resistant technology, applied in the direction of chemical instruments and methods, laminating devices, paper/cardboard layered products, etc., can solve the problems of inability to achieve good antistatic performance, unfavorable overall performance of the countertop, and poor antistatic methods. Ideal and other issues, to achieve the effect of increasing antistatic performance, stable structure, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0062] The preparation of the substrate layer is as follows:

[0063] Place the quantified kraft paper in thermosetting phenolic resin, impregnate at a speed of 27-45m / min, and dry at 130-150°C after impregnation, with a machine speed of 27-45m / min; After completion, a single-layer kraft paper layer can be obtained. The sizing amount of the kraft paper is 45-60% (the sizing amount refers to: the sizing amount of the resin impregnated on the kraft paper accounts for 45-60% of the pure surface paper mass before sizing), and the volatile matter when dry It is 7.5-9.5% (the volatile content refers to the percentage of moisture and volatile small molecular substances contained in the impregnated kraft paper in the mass of the impregnated kraft paper;).

[0064] In the actual use process, the number of kraft paper sheets is determined according to the actual use situation, and multiple sheets of kraft paper are combined to obtain the substrate layer.

[0065] The anti-corrosion an...

Embodiment 1

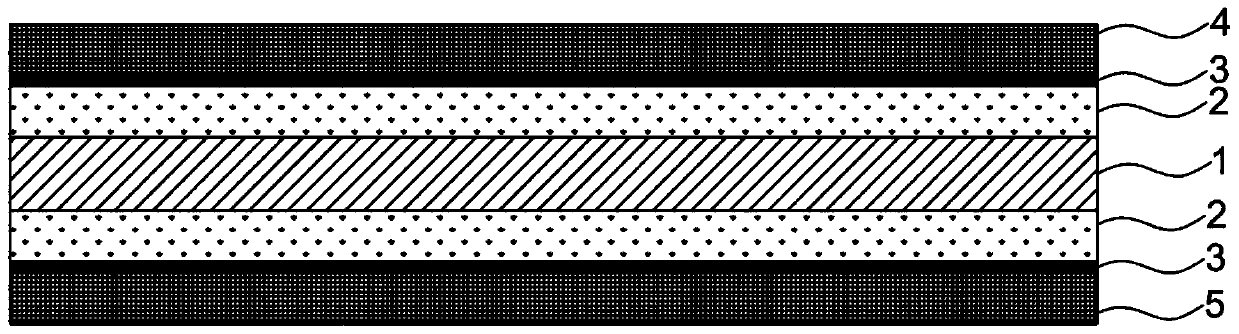

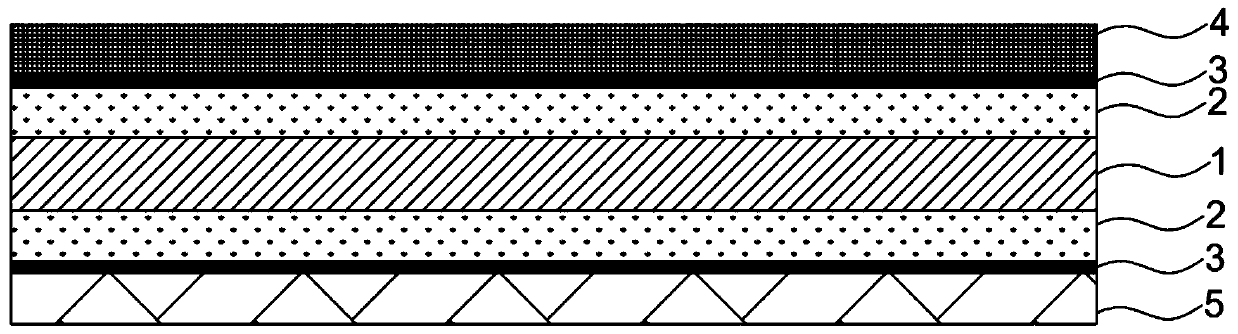

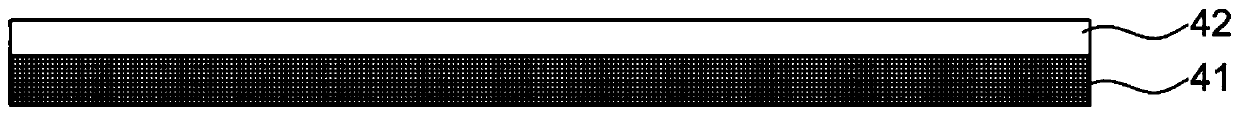

[0108] A corrosion-resistant and anti-static decorative table top, such as figure 1 , image 3 As shown, the countertop includes a substrate layer 1, an antistatic layer 2, an adhesive layer 3 and a first corrosion-resistant and antistatic decorative layer 4 arranged sequentially on the upper surface of the substrate layer 1 from inside to outside; An antistatic layer 2, an adhesive layer 3 and a second corrosion-resistant and antistatic decorative layer 5 on the lower surface of the substrate layer 1;

[0109] The substrate layer 1 is obtained by stacking and bonding multiple layers of kraft paper impregnated with thermosetting phenolic resin. Single-layer kraft paper is 100g / m 2 , the thickness of kraft paper impregnated with resin and hot-pressed is 0.1mm;

[0110] Usually the required thickness of the substrate layer is 10-14mm.

[0111] The antistatic layer 2 is a carbon crystal antistatic layer, and the carbon crystal antistatic layer is 100~120g / m 2 carbon crystal ...

Embodiment 2

[0121] A method for preparing a corrosion-resistant and antistatic decorative table top, the method comprising the following steps:

[0122] (1) Preparation of corrosion-resistant and antistatic decorative layer:

[0123] According to the required ratio, add the measured polyurethane acrylate resin, diluent, antistatic agent, photoinitiator, thermosetting agent, and mold release agent into the stirring tank in proportion, and heat up from room temperature to 40-50 °C in the stirring tank. ℃, and stirred at this temperature for 20 to 30 minutes;

[0124] Then, the roll-shaped decorative paper is coated with the stirred resin mixture on its upper surface by the coating roller of the horizontal coating machine; The speed of the machine is 10-15m / min; after solidification is completed, it is cooled to room temperature by a water-cooled roller, and then cut into the required length;

[0125] Among them, the coating amount of resin is 120~170g / m 2 The thickness of the coating lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com