Reinforced composite pipeline

A composite pipe, enhanced technology, applied in the direction of pipeline protection, pipeline damage/abrasion prevention, pipes, etc., can solve the problems of increasing pipe weight and cost, strength, compressive performance not meeting the requirements, low compressive strength, etc. To achieve the effect of tight bonding between layers, preventing fracture or frost cracking, and increasing bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

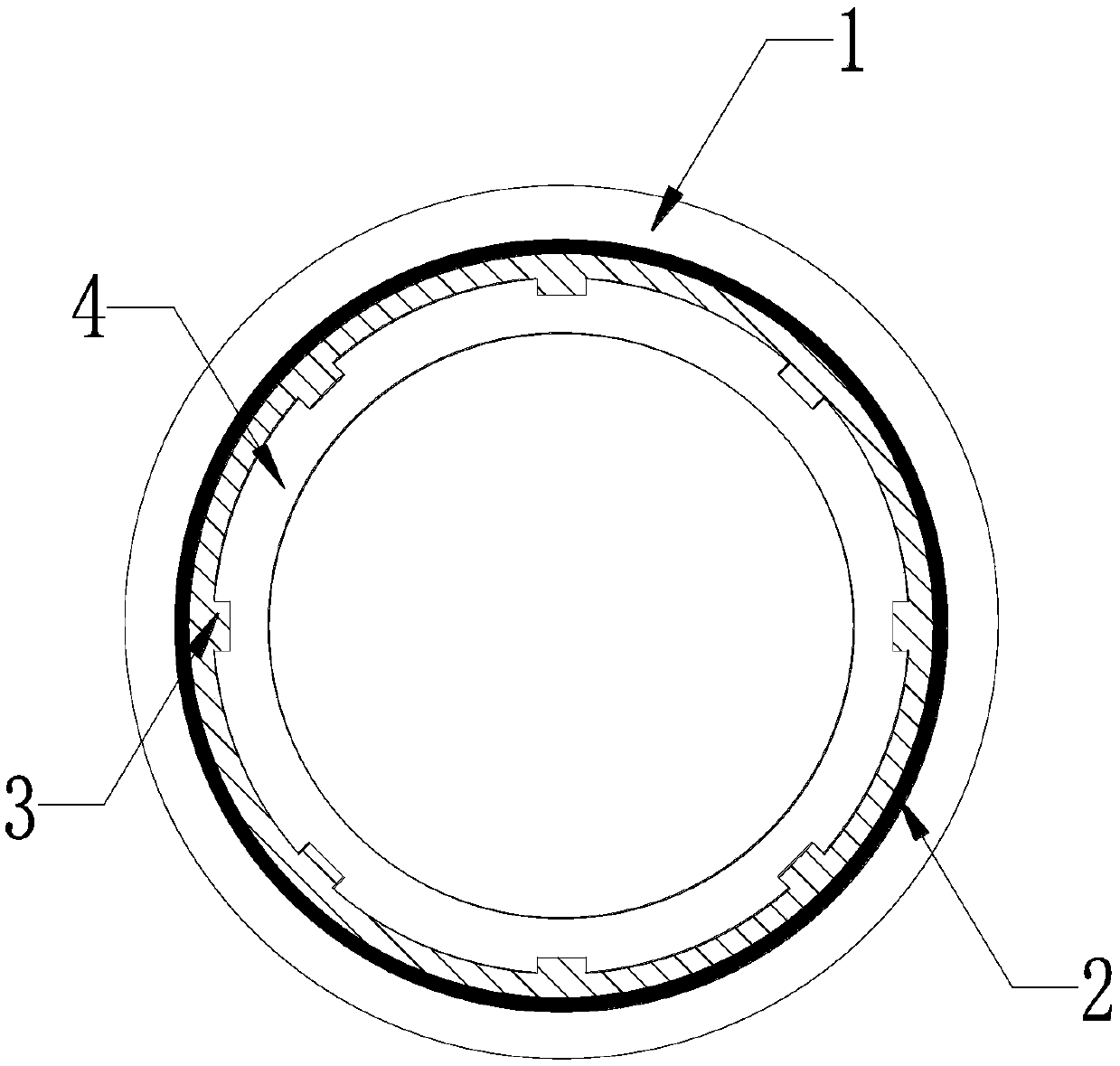

[0017] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0018] like figure 1 and figure 2 As shown, a reinforced composite pipe is provided with a polyethylene fiber outer layer 1, a plastic resin layer 2, a steel mesh reinforcement layer 3 and a polyethylene inner layer 4 sequentially from outside to inside, and the polyethylene fiber outer layer 1 is made of co-extrusion of mesh cloth and polyethylene material, the steel mesh reinforcement layer 3 is a mesh structure in which longitudinal steel wires and horizontal steel wires intersect, and the plastic resin layer 2, polyethylene The inner layer 4 is fused into one body after passing through the through hole of the steel mesh reinforcement layer 3 .

[0019]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com