A Secondary Structure Inerter with Adjustable Coefficient of Inertia

A technology of inertia coefficient and secondary structure, which is applied in the direction of inertial effect shock absorbers, shock absorbers, shock absorbers, etc., can solve the problems of time lag of inertia coefficient, etc., and achieve prolonging service life, not easy to fail, and reducing the number of components little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below with reference to the drawings and specific embodiments, but the protection scope of the present invention is not limited to this.

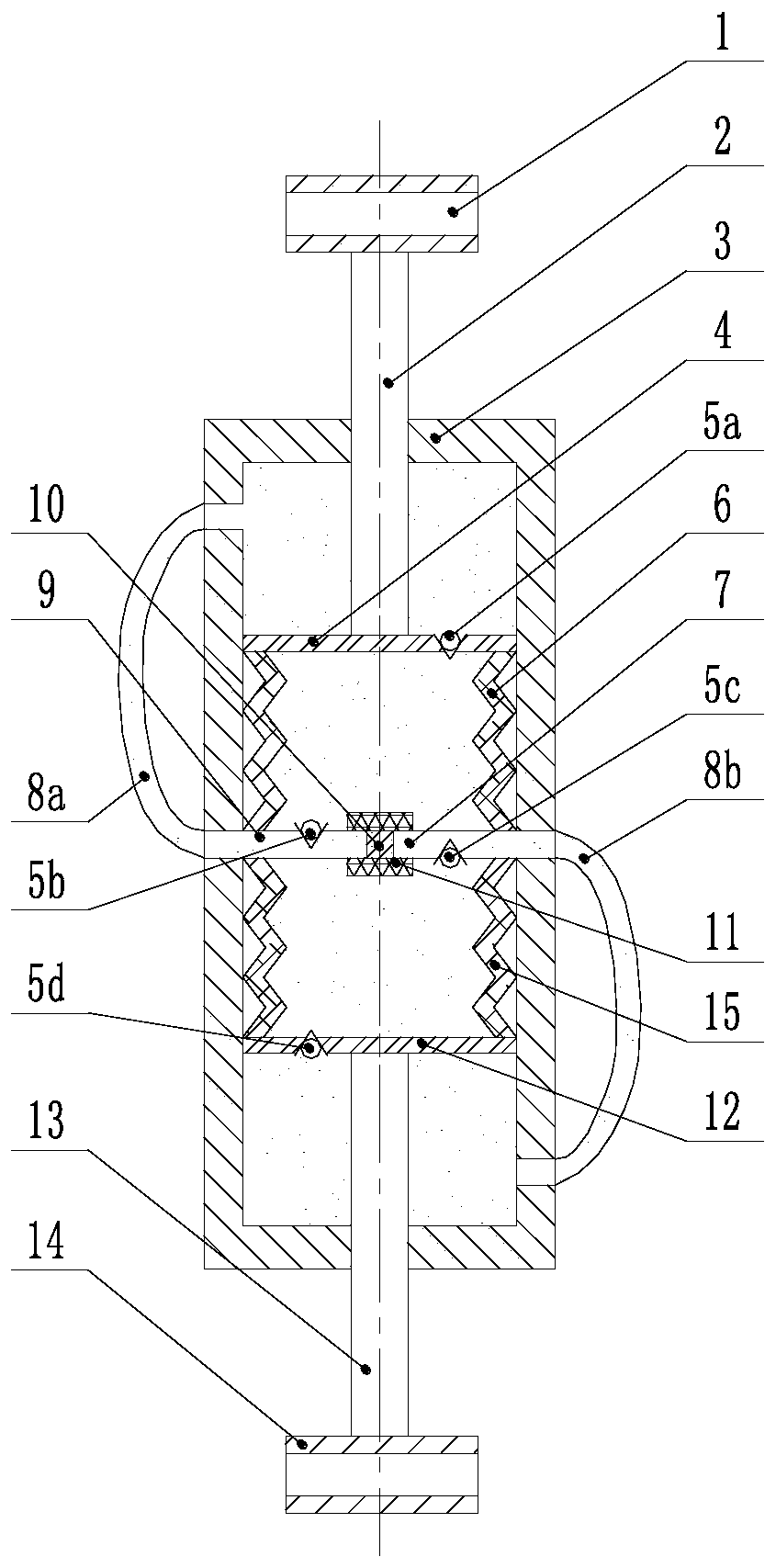

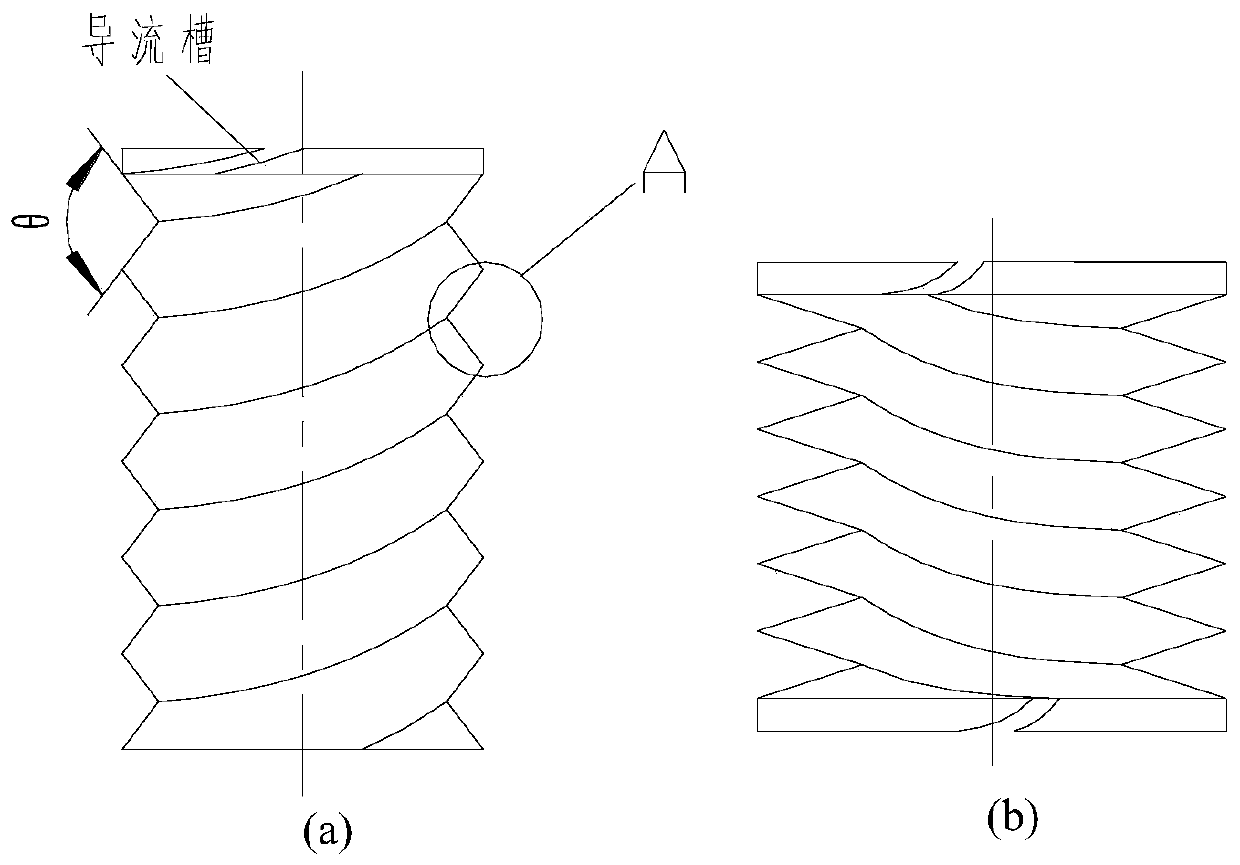

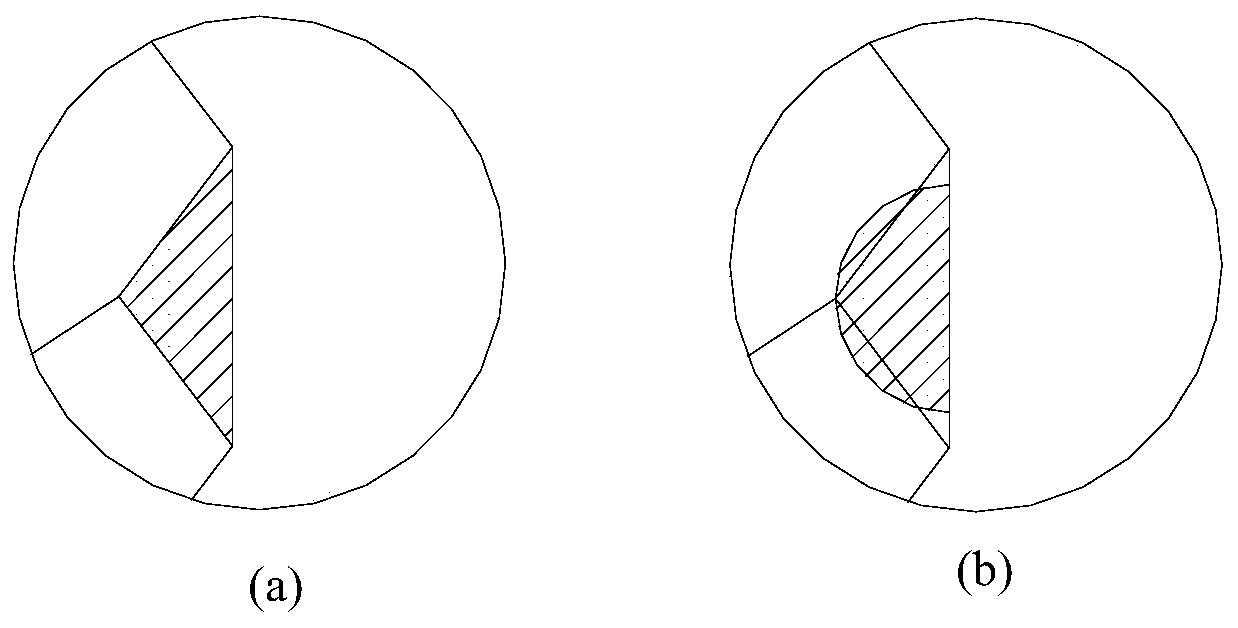

[0028] Such as figure 1 As shown, a secondary structure inertia vessel with adjustable inertia coefficient includes a hydraulic cylinder 3, an inertial force generator A6, an inertial force generator B15, an upper piston rod 2, a lower piston rod 13, and a connecting pipe 8. Block channel

[0029] The hydraulic cylinder 3 is divided into an upper cylinder and a lower cylinder by the blocking channel. A blocking block 10 is installed inside the blocking channel. The blocking channel is divided into a left channel 9 and a right channel 7, and a left channel 9 and a right channel 7 There is no communication between the upper and lower cylinders.

[0030] A through hole is opened on the cylinder wall of the upper cylinder, which is connected to the left end of the blocking channel through a commu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com