Hot melt glue for novel lining cloth and preparation method thereof

A technology of hot melt adhesive and interlining, applied in the direction of adhesives, epoxy resin adhesives, adhesive types, etc., can solve the problem of increasing cost, and achieve the effect of good high temperature resistance, excellent adhesion performance and good compatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

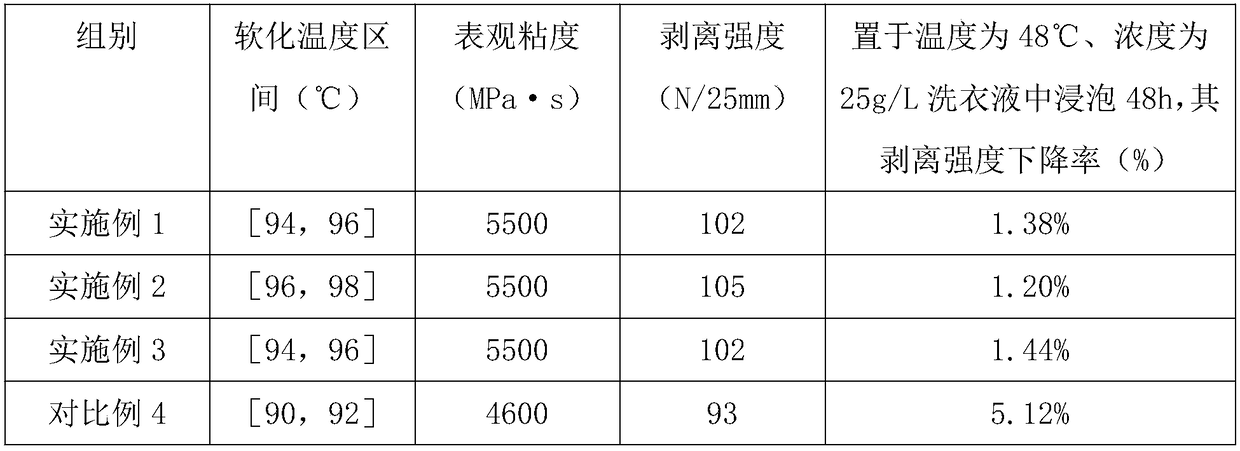

Examples

Embodiment 1

[0033] A new type of hot melt adhesive for interlining, prepared by weighing the following raw materials: 40kg of modified polyester resin, 20kg of F-type epoxy resin, 10kg of modified bone glue, 3kg of polybutyl acrylate, 1kg of sodium bentonite, and 1kg of viscose fiber , carboxymethyl cellulose 1kg, polydimethylsiloxane 0.4kg, high resilience silicone oil 2kg, aluminum dihydrogen phosphate 0.1kg, tributyl phosphate 0.8kg, phthalate polyester 0.3kg, antioxidant 10101kg, coupling agent: aminosilane coupling agent KH-5501kg and initiator: tert-butyl peroxybenzoate 2kg;

[0034] Above-mentioned modified polyester resin is made through the following steps:

[0035] Step 1: Weigh the following components: terephthalic acid 8kg, adipic acid 7kg, trimellitic anhydride 6kg, trimethylolpropane 4kg, dipentaerythritol 7kg, neopentyl glycol 8kg and polymerization catalyst: monobutyltin oxide 0.2kg;

[0036] Step 2: Add all the ingredients required for the modified polyester resin into ...

Embodiment 2

[0045] A new type of interlining hot melt adhesive, prepared by weighing the following raw materials: 45kg of modified polyester resin, 25kg of F-type epoxy resin, 12kg of modified bone glue, 4kg of polybutyl acrylate, 1.5kg of sodium bentonite, viscose fiber 1.25kg, carboxymethyl cellulose 2kg, polydimethylsiloxane 0.6kg, high resilience silicone oil 2.5kg, aluminum dihydrogen phosphate 0.3kg, tributyl phosphate 1kg, phthalate polyester 0.5kg, Oxygen agent 10762kg, coupling agent: epoxy silane coupling agent KH-5601.5kg and initiator: tert-butyl peroxy tert-valerate 3kg;

[0046] Above-mentioned modified polyester resin is made through the following steps:

[0047] Step 1: Weigh the following components: terephthalic acid 8.5kg, adipic acid 8kg, trimellitic anhydride 7kg, trimethylolpropane 5kg, dipentaerythritol 8kg, neopentyl glycol 8.5kg and polymerization catalyst: dibutyl dilauric acid Tin 0.25kg;

[0048] Step 2: Add all the ingredients required for the modified polye...

Embodiment 3

[0057] A new hot-melt adhesive for interlining is prepared by weighing the following raw materials: 50kg of modified polyester resin, 30kg of F-type epoxy resin, 15kg of modified bone glue, 5kg of polybutyl acrylate, 2kg of sodium bentonite, and 1.5kg of viscose fiber kg, carboxymethyl cellulose 3kg, polydimethylsiloxane 0.8kg, high resilience silicone oil 3kg, aluminum dihydrogen phosphate 0.5kg, tributyl phosphate 1.2kg, phthalate polyester 0.7kg, antioxidant Agent 10103kg, coupling agent: azidosilane coupling agent S-30462kg and initiator: tert-butyl peroxy tert-valerate 4kg;

[0058] Above-mentioned modified polyester resin is made through the following steps:

[0059] Step 1: Weigh the following components: 9kg terephthalic acid, 9kg adipic acid, 8kg trimellitic anhydride, 6kg trimethylolpropane, 9kg dipentaerythritol, 9kg neopentyl glycol and polymerization catalyst: 0.3kg dibutyltin diacetate ;

[0060] Step 2: Add all the ingredients required for the modified polyest...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com