Punching polyethylene self-adhered waterproof coiled material as well as preparation method and using method thereof

A self-adhesive waterproof membrane, polyethylene technology, applied in the direction of adhesives, film/sheet adhesives, etc., can solve the problems of substandard performance of lap joints, and achieve the improvement of poor adhesion and improved deformation ability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with embodiment, further illustrate the present invention.

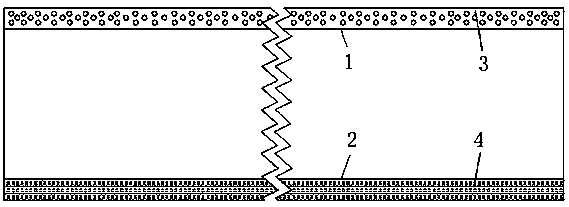

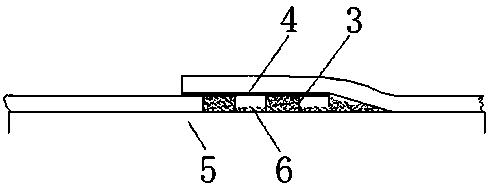

[0031] see figure 1 It can be seen that a perforated polyethylene self-adhesive waterproof membrane of the present invention has a perforated area 1 and a self-adhesive area 2 respectively on both sides of the coiled material along the length direction of the coiled material; The connecting hole 3 and the bonding hole 3 are through holes; the self-adhesive area 2 is scraped and coated with self-adhesive glue 4 .

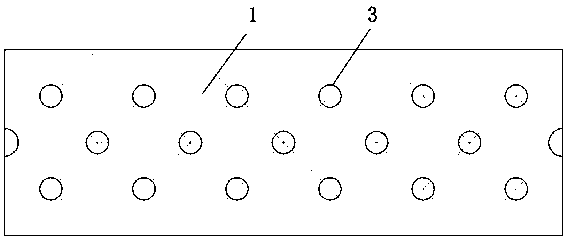

[0032] see figure 2 It can be seen that the bonding holes 3 are circular holes, and the bonding holes 3 are evenly spaced.

[0033] The shape of the circular holes is regular, the bonding force is balanced, and the bonding holes 3 are evenly spaced to further improve the firmness of the connection between the product and the base layer 5 .

[0034] The width of perforated area 1 and self-adhesive area 2 is 20mm-120mm.

[0035] The width of perforated area 1 and self-adhesive...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com