Environment-friendly EVA waterproof coil and preparation method thereof

A kind of waterproof roll material and environment-friendly technology, which is applied in the field of tunnel waterproof materials, can solve the problems of affecting welding performance, separation of mixed phases of powder and granular materials, closed and narrow space of construction tunnels, etc., and achieves good anti-aging performance and flame retardant performance , avoid phase separation and precipitation, and reduce the effect of relative addition amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] A preparation method of an environment-friendly EVA waterproof coiled material, specifically comprising the following steps:

[0039] A. Weigh the corresponding raw materials according to the ratio.

[0040] Before raw material is weighed, at first prepare anti-aging-flame-retardant master batch, the preparation method of anti-aging-flame-retardant master batch comprises the following steps:

[0041] A1. Grind the flame retardant and flame retardant synergist, and pass through a 800 mesh sieve;

[0042] A2. Add flame retardant and flame retardant synergist to a high-speed mixer preheated to 70-90°C, add coupling agent and mix for activation for 5-10 minutes;

[0043] A3. Weigh the light stabilizer, antioxidant, and heat stabilizer according to the proportion and add them to the high-speed mixer and stir for 5-10min;

[0044] A4. Weigh ethylene-vinyl acetate copolymer, metallocene polyethylene and high-density polyethylene respectively according to the proportion and a...

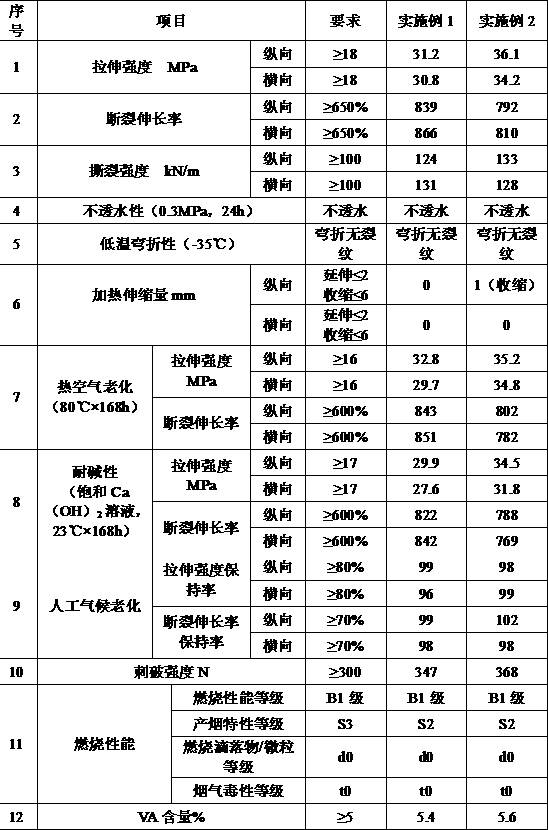

Embodiment 1

[0052] An environmentally friendly EVA waterproof membrane, including the following components by weight: ethylene-vinyl acetate copolymer EVA (VA content 18%) is 30%, metallocene polyethylene mPE is 15%, high-density polyethylene HDPE is 40% %, anti-aging - flame retardant masterbatch 15%. Among them, the anti-aging-flame retardant masterbatch includes the following components by weight: ethylene-vinyl acetate copolymer EVA (VA content 18%) 25%, metallocene polyethylene mPE 5%, high-density polyethylene HDPE 5% , ultraviolet absorber UV-327 is 2%, free radical scavenger LS744 is 1%, hindered phenolic antioxidant 1010 is 3%, secondary antioxidant 168 is 4%, main stabilizer zinc stearate is 5% , co-stabilizer triphenyl phosphite is 2%, flame retardant organic silanolamide is 30%, phosphate ester is 10%, flame retardant synergist magnesium stearate is 5%, silane coupling agent is 1%, EVA wax is 2%.

[0053] The preparation method of this embodiment includes the following steps...

Embodiment 2

[0059] In this example, the environment-friendly EVA waterproof membrane includes the following components by weight: ethylene-vinyl acetate copolymer EVA (28% VA content) is 20%, metallocene polyethylene mPE is 30%, high-density polyethylene HDPE 35%, anti-aging-flame retardant masterbatch 15%. Among them, the anti-aging-flame retardant masterbatch includes the following components by weight fraction: ethylene-vinyl acetate copolymer EVA (VA content 28%) 20%, metallocene polyethylene mPE 5%, high-density polyethylene HDPE 5% , ultraviolet absorber UV-531 is 2%, free radical scavenger LS744 is 1%, hindered phenolic antioxidant 1076 is 5%, secondary antioxidant 168 is 7%, main stabilizer zinc stearate is 5% , co-stabilizer triphenyl phosphite is 2%, flame retardant organic silanolamide is 30%, phosphate ester is 10%, flame retardant synergist magnesium stearate is 5%, silane coupling agent is 1%, EVA wax is 2%.

[0060] The preparation method of this example is the same as th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com