Composite material which has high thermal conductivity and electromagnetic shielding function and preparation method thereof

A composite material and electromagnetic shielding technology, applied in the direction of heat exchange materials, magnetic field/electric field shielding, chemical instruments and methods, etc., can solve problems such as inability to achieve heat conduction effect, affect product performance and service life, and large resistivity. Easy to repair, good mechanical strength, easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

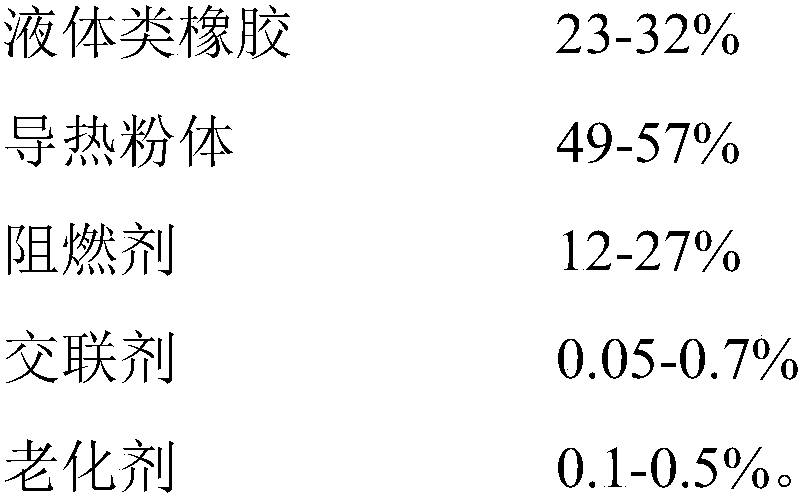

Method used

Image

Examples

preparation example Construction

[0028] The preparation method of the composite material is as follows: firstly, the components of the lower layer material composition are vacuum mixed by a power mixer, and then the mixture is coated with the lower layer material composition vulcanized into an elastic sheet by using a coating device; then the upper layer material is The components of the composition are mixed by a high-speed mixer to obtain the upper layer material composition, and then the lower layer material composition of the sheet is placed on the spraying equipment, and the upper layer material composition is sprayed evenly on the lower layer material composition, and then vulcanized, that is A composite material with high thermal conductivity and electromagnetic shielding function is obtained.

[0029] The prepared composite materials were tested for thermal conductivity, resistivity and flame retardancy. Among them, the thermal conductivity test used Hotdisk testing equipment; the dielectric constant t...

Embodiment 1

[0032] Lower material preparation: 24 grams of polyacrylate rubber with a viscosity of 8000 centistokes, 10 grams of boron nitride (Saint-Gobain, USA) with a particle size of 20 microns, 35 grams of graphitized carbon fiber powder with a particle size of 100 microns (Japan Carbon element), 7 grams of graphene (self-made), 25 grams of phosphorus nitrogen flame retardant (Dongguan Daoer New Materials), 0.5 grams of dibenzoyl peroxide and 0.5 grams of anti-aging agent D (N-phenyl-β-naphthalene Amine) placed in a stirrer with a rotation speed of 30 rpm and a vacuum degree of -0.08 or less and stirred for 30 minutes to make the components evenly mixed. Pour the stirred mixture into the feeding platform of the coating equipment, adjust the thickness to 1.0 mm, and place it in an oven at 150° C. for 10 minutes for vulcanization to obtain an elastic sheet-shaped lower layer material composition 20 .

[0033] Preparation of the upper material: 17.6 grams of polyacrylate rubber with a v...

Embodiment 2

[0037] Lower material preparation: 23 grams of polyacrylate rubber with a viscosity of 5000 centistokes, 17 grams of boron nitride (Saint-Gobain, USA) with a particle size of 10 microns, 33.4 grams of graphitized carbon fiber powder with a particle size of 100 microns (Japan Carbon element), 3 grams of graphene (self-made), 23 grams of phosphorus nitrogen flame retardant (Dongguan Daoer New Materials), 0.5 grams of dibenzoyl peroxide and 0.1 grams of anti-aging agent D (N-phenyl-β-naphthalene Amine) placed in a stirrer with a rotation speed of 30 rpm and a vacuum degree of -0.08 or less and stirred for 30 minutes to make the components evenly mixed. Pour the stirred mixture into the feeding platform of the coating equipment, adjust the thickness to 2.0 mm, place it in an oven at 150° C. for 10 minutes for vulcanization, and obtain an elastic sheet-shaped lower layer material composition 20 .

[0038]Preparation of upper material: 21.6 grams of polyacrylate rubber with a viscos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com