Preparation method and application of rhenium disulfide nanoflake

A rhenium disulfide and nanosheet technology, which is applied in the field of preparation of single-layer and/or few-layer rhenium disulfide nanosheets, can solve the problems of high cost and harsh reaction conditions, and achieve low cost, high reactivity and low price Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] 0.5000g ammonium rhenate ((NH 4 ) 2 ReO 4 ) and 0.5400g sodium ethyl xanthate (C 3 h 5 OS 2 Na) were dissolved in 30mL deionized water respectively, and after being completely dissolved, the (NH 4 ) 2 ReO 4 The pH of the solution was adjusted to 7.00, after which the C 3 h 5 OS 2Na solution was added to it and mixed evenly. The mixture was transferred to a 100mL autoclave, sealed, placed in an oven at 200°C for 8 hours, and cooled to room temperature naturally. After the reaction product is separated, it is washed with deionized water and absolute ethanol several times, collected and vacuum freeze-dried to obtain a black powder product, which is rhenium disulfide material. Among them, ammonium rhenate is almost quantitatively converted to rhenium disulfide.

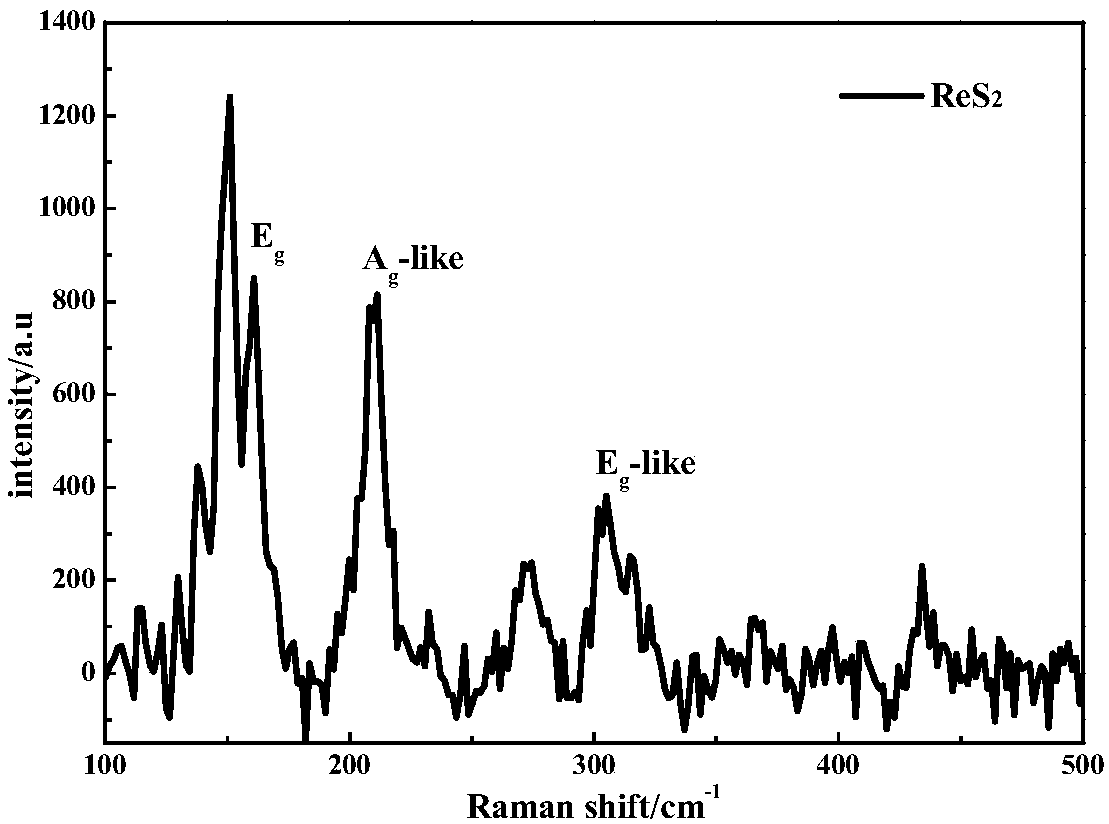

[0047] figure 1 The field emission scanning electron microscope (FESEM) picture of the rhenium disulfide material prepared for this embodiment, from figure 1 It can be seen that it is composed of many...

Embodiment 2

[0049] 0.5000g ammonium rhenate ((NH 4 ) 2 ReO 4 ) and 0.5400g sodium ethyl xanthate (C 3 h 5 OS 2 Na) were dissolved in 30mL deionized water respectively, and after being completely dissolved, C 3 h 5 OS 2 Na solution was added (NH 4 ) 2 ReO 4 solution, mix the two evenly. The mixture was transferred to a 100mL autoclave, sealed, placed in an oven at 200°C for 10h, and cooled to room temperature naturally. After the reaction product is separated, it is washed with deionized water and absolute ethanol several times, collected and vacuum freeze-dried to obtain a black powder product, which is rhenium disulfide material. Among them, ammonium rhenate is almost quantitatively converted to rhenium disulfide.

Embodiment 3

[0051] 0.5000g ammonium rhenate ((NH 4 ) 2 ReO 4 ) and 0.5400g sodium ethyl xanthate (C 3 h 5 OS 2 Na) were dissolved in water respectively, and after being completely dissolved, the (NH 4 ) 2 ReO 4 The pH of the solution was adjusted to 9.00, after which the C 3 h 5 OS 2 Na solution was added to it and mixed evenly. The mixture was transferred to a 100mL autoclave, sealed, placed in an oven at 190°C for 12h, and cooled to room temperature naturally. After the reaction product is separated, it is washed with deionized water and absolute ethanol several times, collected and vacuum freeze-dried to obtain a black powder product, which is rhenium disulfide material. Among them, ammonium rhenate is almost quantitatively converted to rhenium disulfide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com