Powder laying device for electron beam titanium alloy powder fusion forming

A technology of powder spreading device and titanium alloy, which is applied in the direction of improving process efficiency, improving energy efficiency, and additive manufacturing, and can solve problems affecting the processing environment, processing efficiency, powder spreading effect, device reliability, and workpiece processing effect, etc., to achieve Good powder spreading effect, good sealing and magnetic isolation, anti-ray function, and perfect structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

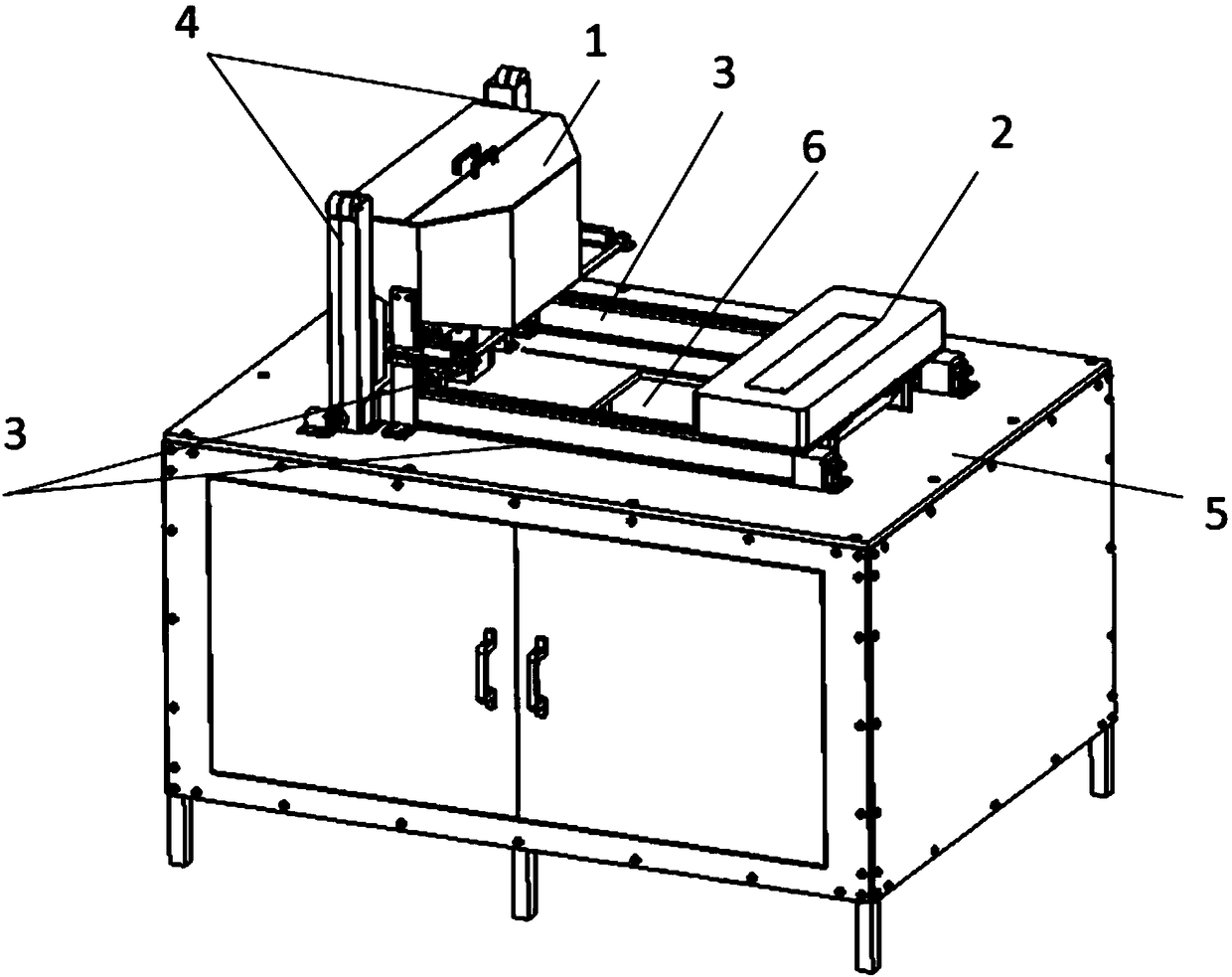

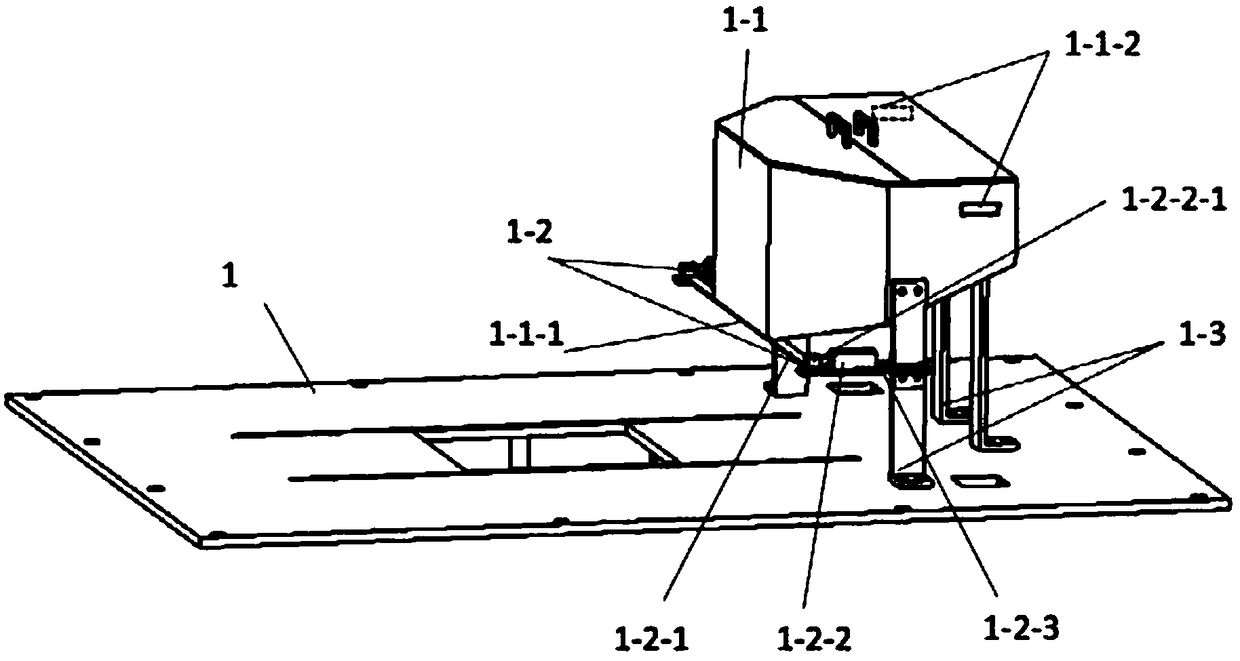

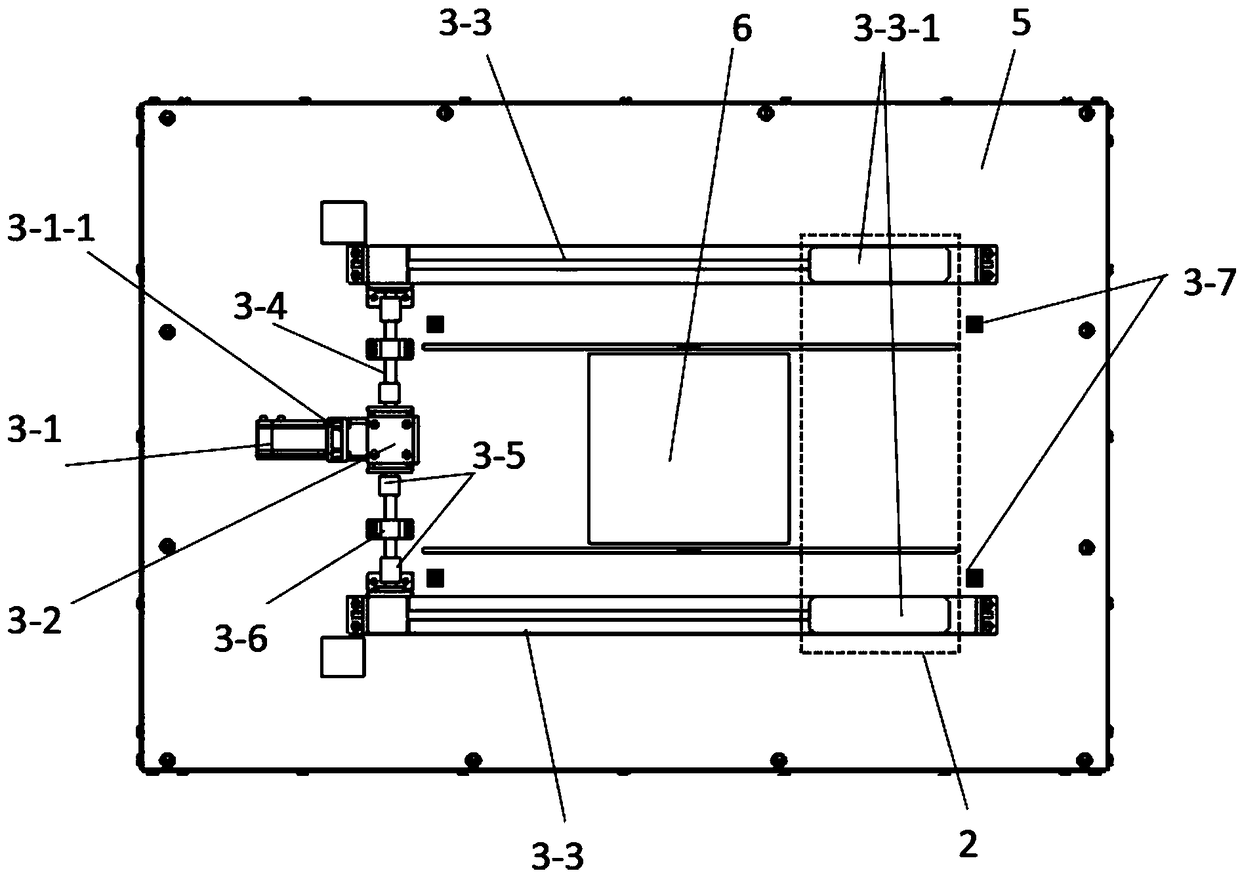

[0053] Such as figure 1 As shown, it includes a powder storage module 1, a powder spreading module 2, a symmetrical linear walking module 3, a surplus material recovery module 4, and a horizontal workbench 5. The workbench 5 is fixedly connected to store the metal powder and deliver the metal powder to the powder spreading module 2 in time. The two identical linear electric cylinders 3-3 in the symmetrical linear walking module 3 are symmetrically arranged on both sides of the molding chamber 6. And fixedly connected to the horizontal workbench 5, at the same time, the mobile connection end 3-3-1 of the linear electric cylinder is fixedly connected with the powder spreading module 2, and the two linear electric cylinders 3-3 are carried out by the motor 3-1 and the corresponding transmission mechanism. Drive synchronously to drive the powder spreading module 2 to carry out linear reciprocating powder spreading movement. The two vertical recovery cylinders 4-3 in the residual m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com