A horizontal ring mold powder spreading device

A powder spreading device, horizontal technology, applied in rings, casting molding equipment, clothing, etc., can solve the problems of uneven powder spreading, complicated powder spreading process, inconvenient operation, etc., achieve good powder spreading effect and improve powder spreading efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

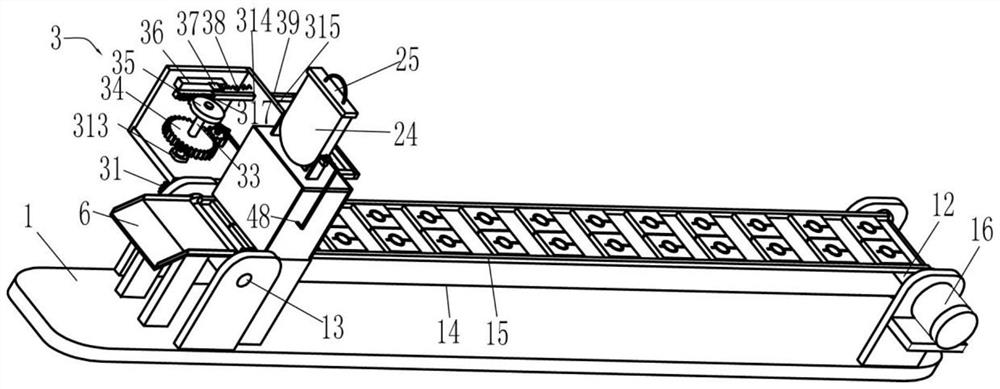

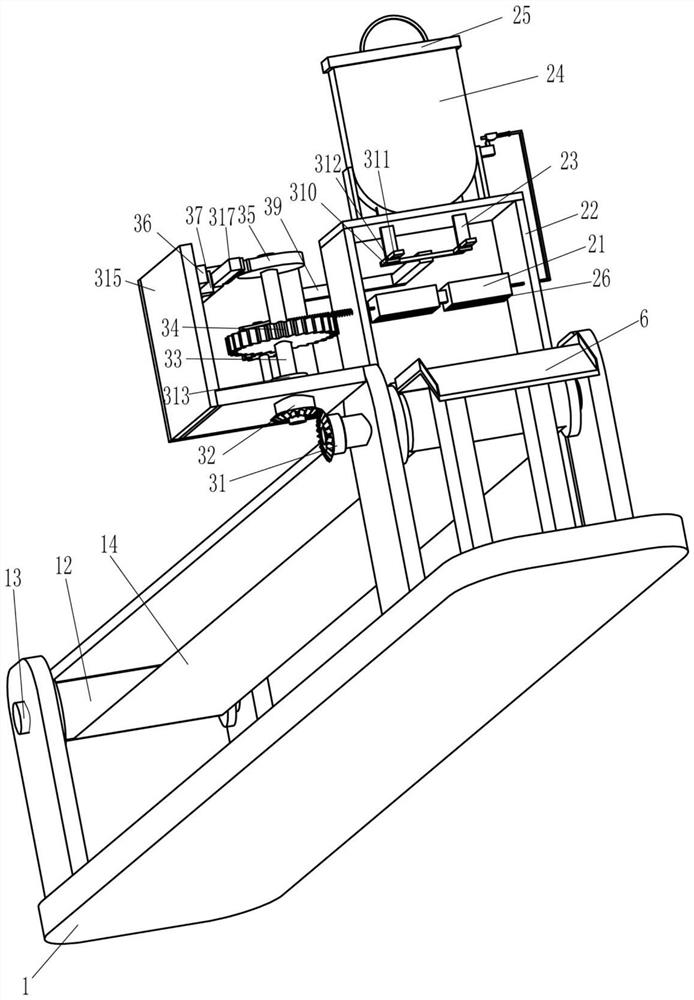

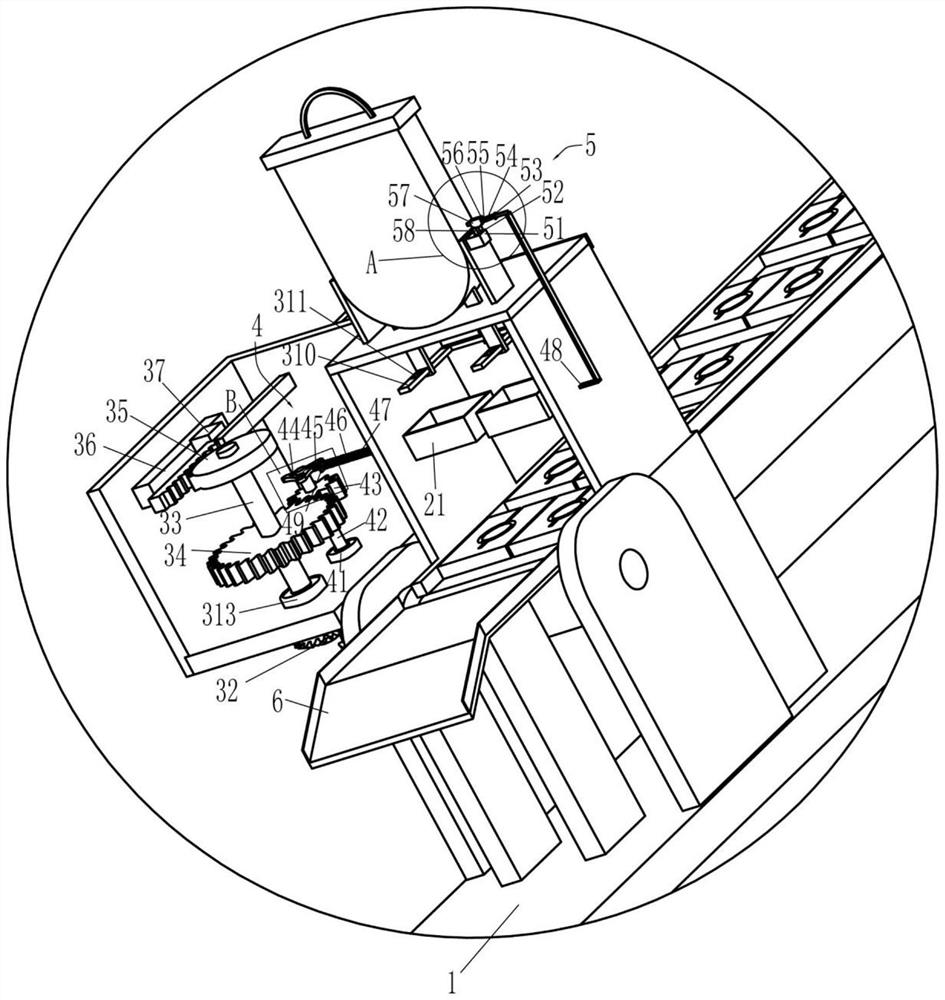

[0022] EXAMPLES: A horizontal rings provided by the present invention, such as Figure 1-7 As shown, including the rack 1, the transfer wheel 12, the conveying shaft 13, the connecting belt 14, the limit strip 15, the motor 16, the homogenate groove 21, the protective frame 22, the powder tube 23, the gas storage tank 24, can The cover 25 and the indirect powder member 3 are attached to the left and right ends of the frame 1, and the conveying shaft 13 is mounted by the bearing, and the two conveying shaft 13 is mounted, and the conveying wheel is attached, and the two conveying shafts 13 are passed through the connecting belt 14. Transmission connection, the frame 1 is mounted on the two-part strip 15 for preventing the ring on both sides from the connecting tape 14 and is located above the connecting belt 14, the motor 16 is mounted at the rightmost portion of the rack 1. The front side and the output shaft are connected to one transfer shaft 13, and the protective frame 22 is fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com