Automatic tray paving device with stacked tray separating function and tray paving method of device

A technology of laying and function, which is applied in the field of automatic laying devices, can solve the problems of aggravating labor force, high labor intensity, and large labor demand, and achieve the effects of stable and reliable transfer, high laying efficiency, and reduced workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with accompanying drawing.

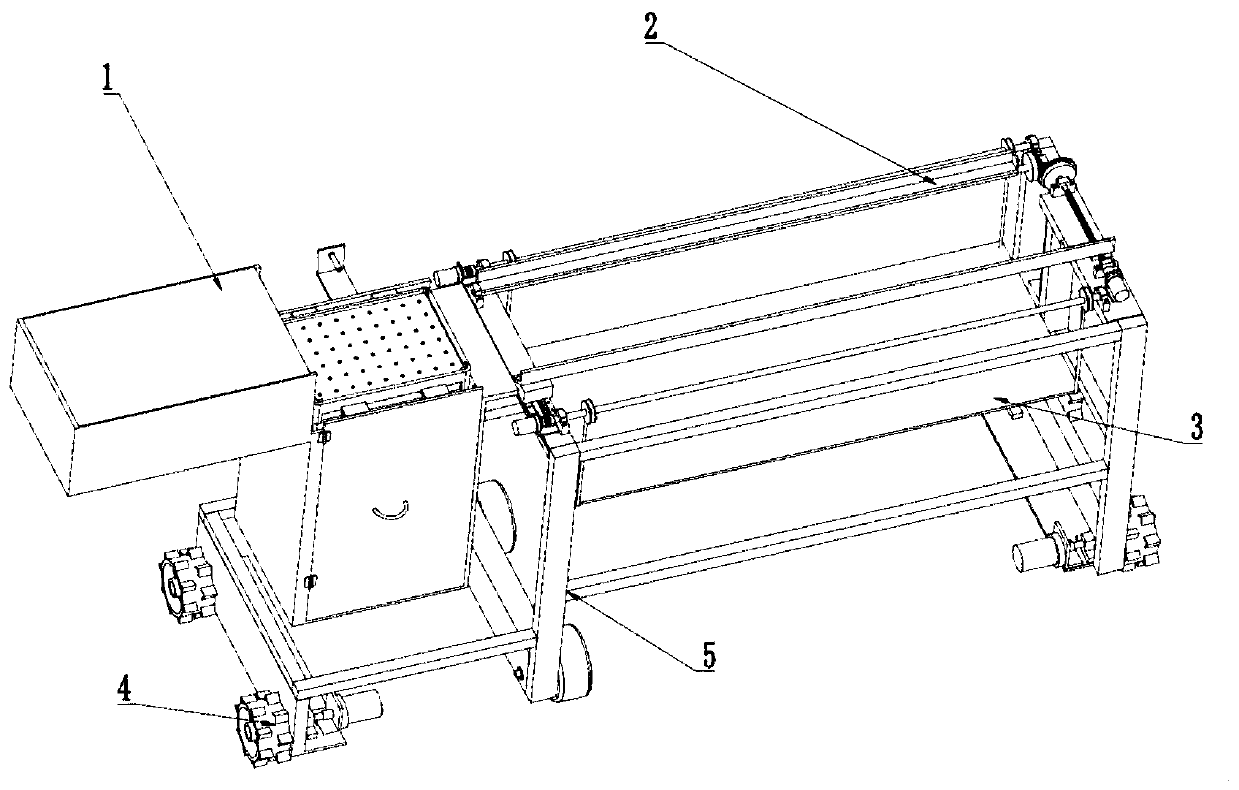

[0043] Such as figure 1As shown, an automatic plate laying device with the function of separating stacked plates includes a plate loading mechanism 1 , a seedling plate temporary storage mechanism 2 , a plate spreading mechanism 3 , a traveling mechanism 4 and a support frame 5 . The upper plate mechanism 1 is arranged on one side of the support frame 5 . Seedling tray temporary storage mechanism 2 is arranged in the support frame 5 . The tray mechanism 3 is arranged on the top of the support frame 5 . The running mechanism 4 is arranged on the bottom of the support frame 5 .

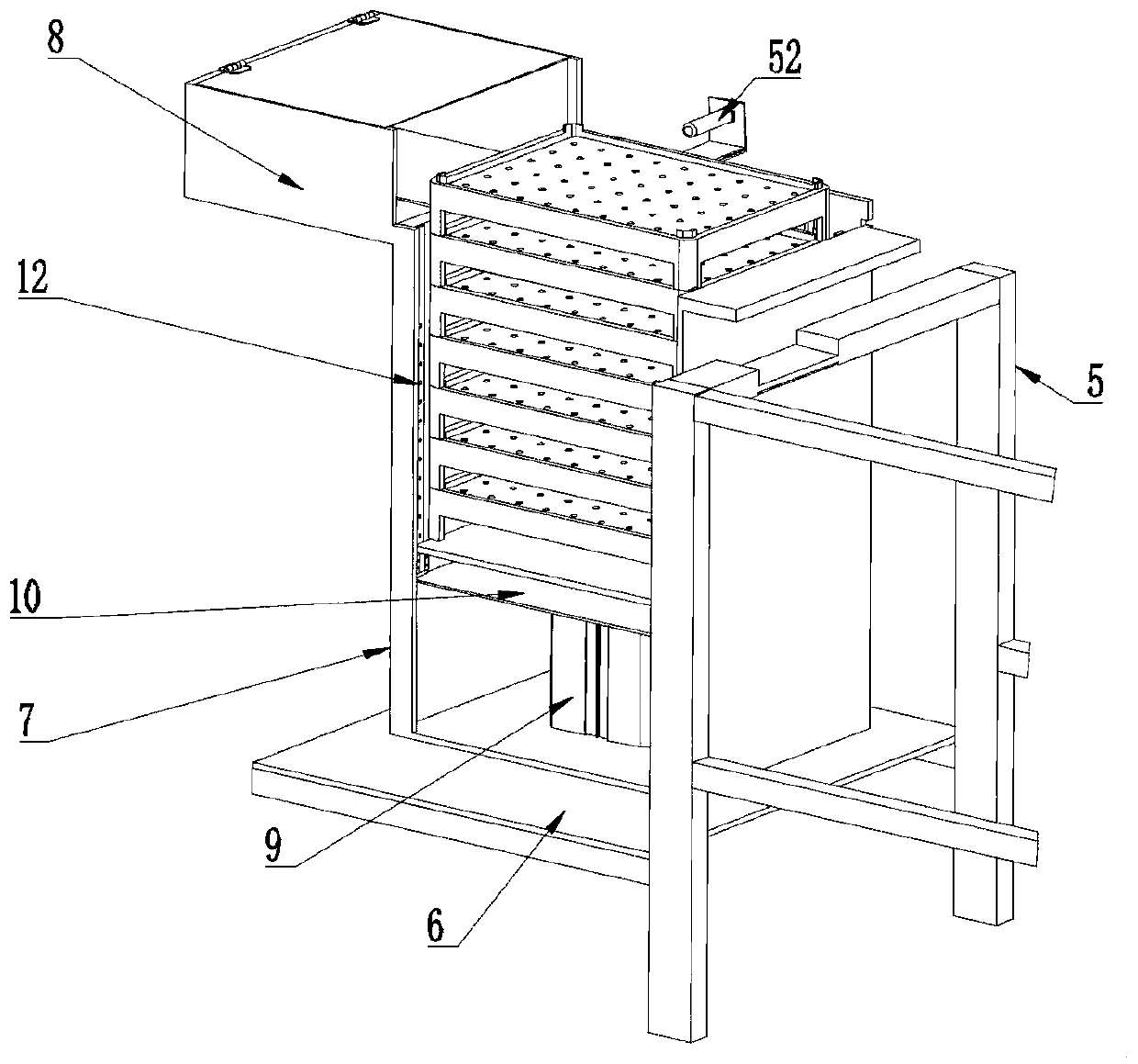

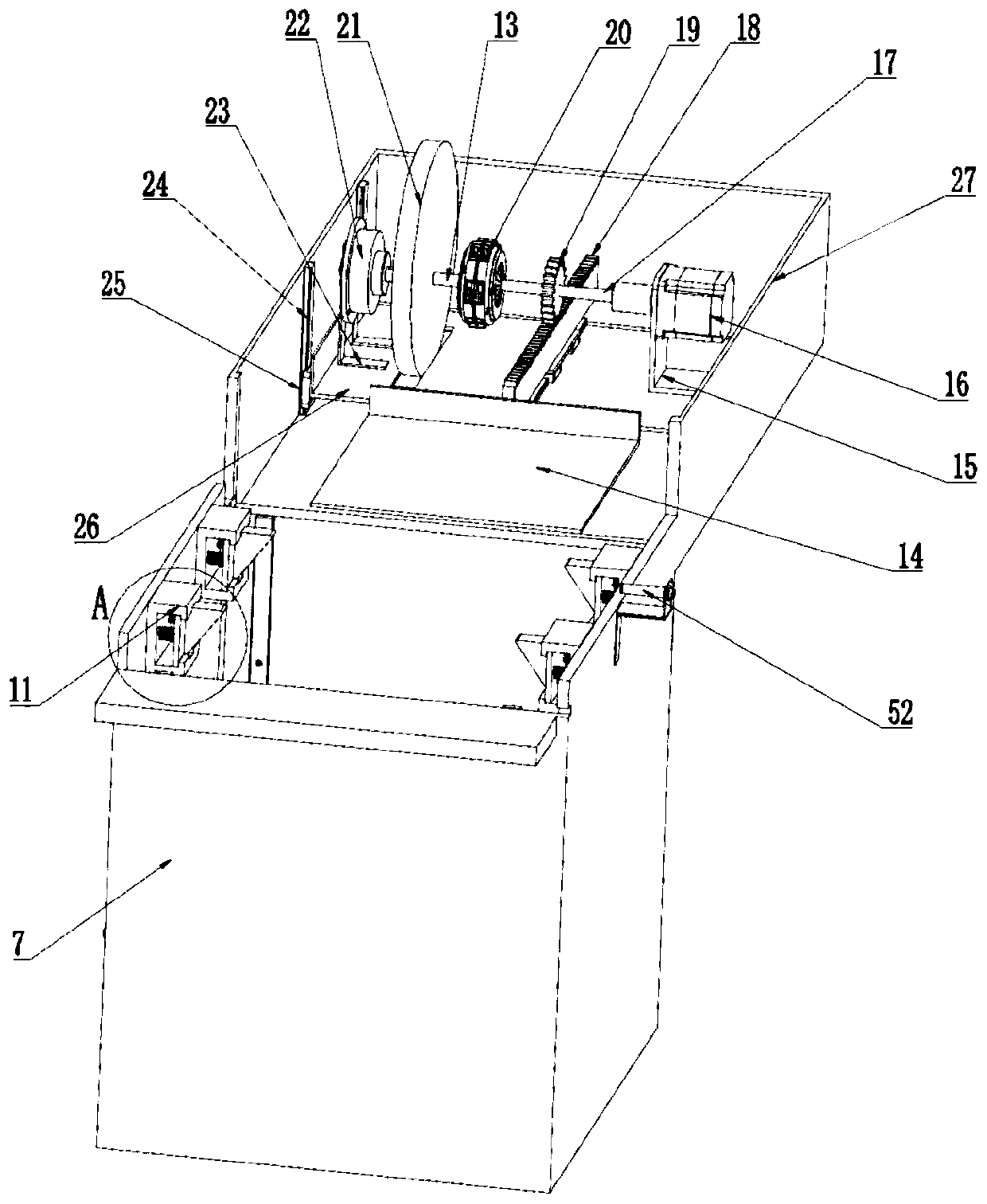

[0044] Such as figure 1 , 2 , 3 and 4, the upper plate mechanism 1 includes a top plate assembly, a push plate assembly 8 and a seedling raising plate. The top plate assembly includes a support plate 6, a storage box 7, a cylinder 9, a seedling plate storage plate 10, a limit button 11, a top p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com