A rapid powder spreading device for powder plate rolling and compounding

A technology of rolling compounding and powder spreading device, which is applied in the field of sliding bearing bush processing, can solve the problems of loose powder, uneven powder spreading, reduced powder spreading effect, etc. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

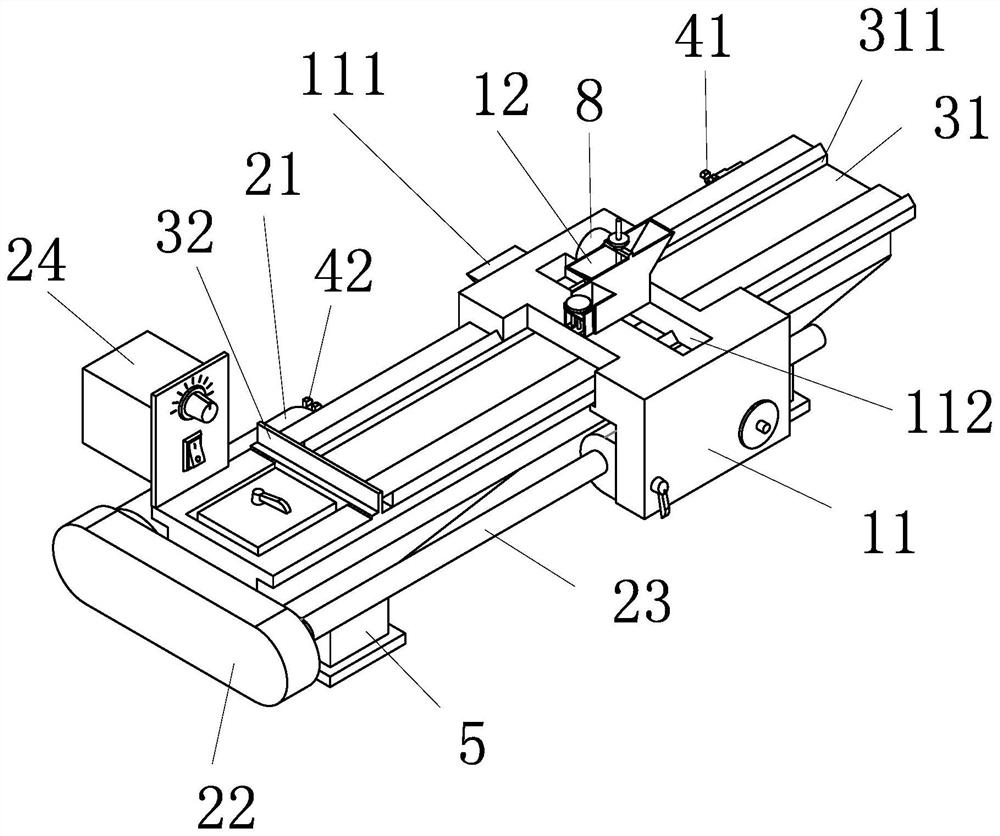

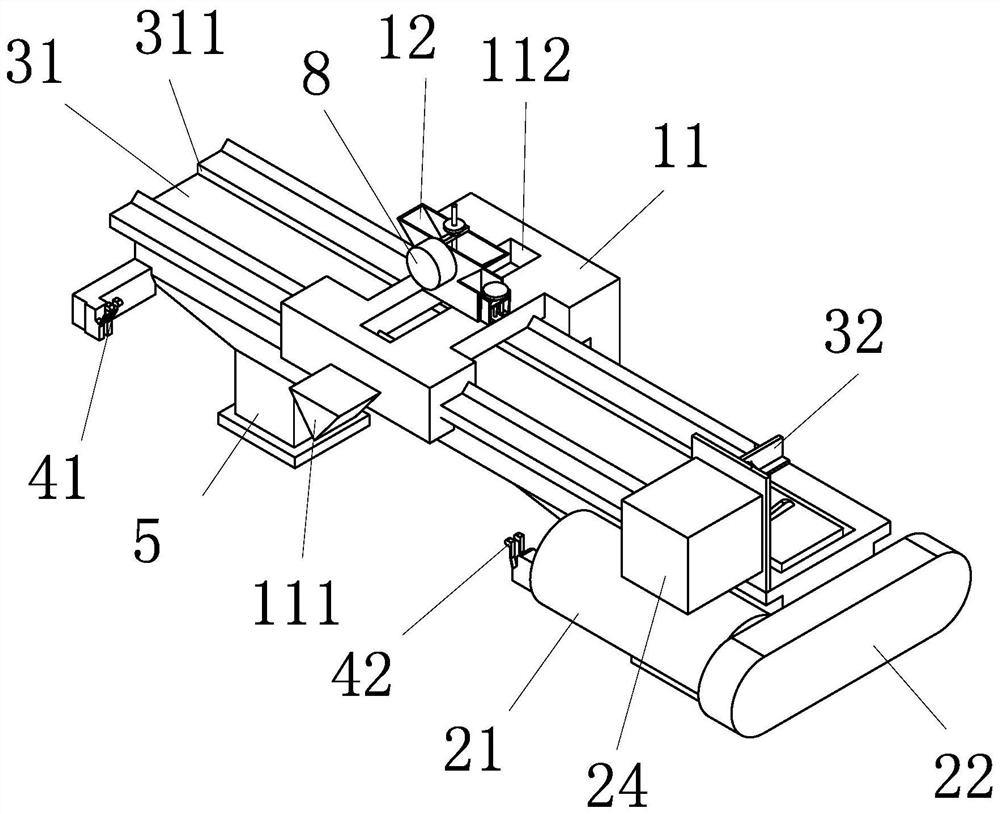

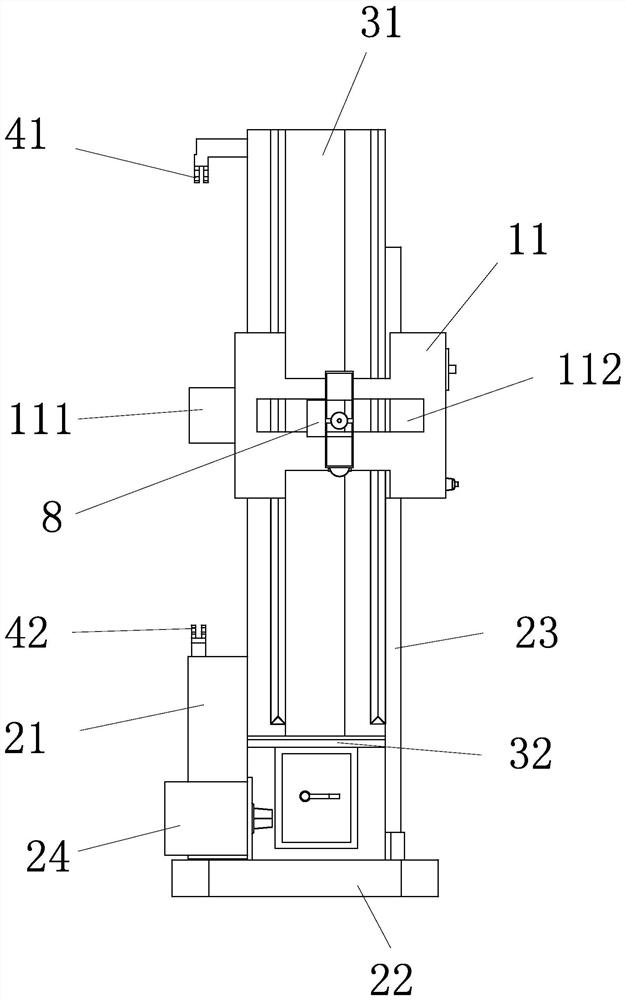

[0038] Such as Figure 1 to Figure 5 As shown, a fast powder spreading device for powder plate rolling and compounding includes a frame 5, a powder spreading device, a vibrating motor 8, a driving device and a control device. The powder spreading device is used for filling powder and discharging powder, and spreading The duster is set above the metal plate and is slidably connected to the frame 5. There is a powder outlet at the bottom of the powder spreader. The vibration motor 8 is fixedly connected to the powder spreader. The vibration motor 8 is provided with a frequency modulation switch. connection, the frequency modulation switch controls the vibration frequency of the vibrating motor 8, the powder in the powder spreader can be dispersed evenly by vibrating the powder spreader, and the powder flows out from the powder outlet and spreads on the metal plate automatically, avoiding the The uneven distribution of powder during the powder spreading process causes the problem...

Embodiment 2

[0041] The structure of this embodiment is basically the same as that of Embodiment 1, the difference is that:

[0042] Such as Figure 1 to Figure 5 As shown, the driving device includes a motor and a lead screw 23, the motor is fixed to the frame 5, and the lead screw 23 is axially arranged parallel to the powder spreading direction. Usually, the powder spreading direction is consistent with the length direction of the metal plate. The powder spreader is provided with a nut matching the lead screw 23, one end of the lead screw 23 is connected to the output shaft of the motor, the other end of the lead screw 23 is screwed to the nut, the motor drives the lead screw 23 to rotate, and the lead screw 23 drives the nut to carry the powder The device moves linearly along the lead screw 23, so that the powder spreader can move linearly above the metal plate along the length direction of the metal plate.

[0043] In addition to the lead screw 23 and the nut, the transmission of the...

Embodiment 3

[0046] The structure of this embodiment is basically the same as that of Embodiment 2, the difference is that:

[0047] Such as Figure 1 to Figure 5 As shown, the frame 5 is provided with a powder spreading platform 31 for carrying metal plates. The length direction of the powder spreading platform 31 is parallel to the axial direction of the lead screw 23. The powder spreading platform 31 is located below the powder spreading device and is slidably connected to the powder spreading device. The setting of the powder spreading platform 31 enables the metal sheet to be placed under the powder spreading device evenly, which is conducive to meeting the accuracy requirements of powder spreading.

[0048] Specifically, linear guide rails are provided on both sides of the powder spreading platform 31, and the linear guide rails are arranged along the powder spreading direction, and the powder spreader slides linearly along the linear guide rails. The setting of the linear guide rail ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com