Slow-release immobilized chlorine dioxide particles and preparation method of particles

A chlorine dioxide, slow-release technology, applied in chemical instruments and methods, botanical equipment and methods, separation methods, etc., can solve the problems of short service cycle, single use, difficult to store, etc., and achieve long service life of finished products. The finished product is safe and reliable, and the effect of improving the shelf life of the finished product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The preparation method of a kind of sustained-release type immobilized chlorine dioxide particle of the present invention is as follows:

[0029] (1) Prepare a mineral acid solution containing a surfactant. The surfactant is one or a mixture of perfluorononoxybenzene sodium sulfonate (OBS), sodium dodecylbenzenesulfonate, sodium lauryl sulfate, cocamidopropyl betaine, The addition amount is 1000-5000 mg / L of the total weight of the acid solution; the inorganic acid is one or a mixture of hydrochloric acid, sulfuric acid, and nitric acid, and the concentration is 0.5-5 mol / L; The acid-modified zeolite particles are obtained by suction filtration after immersing in an acid solution added with a surfactant at a ratio of 1:10 to 1:20 by weight to volume. The crystal structure of natural zeolite consists of three parts: aluminosilicate framework, the pores and cavities of exchangeable cations in the framework, and water molecules in the potential phase; this structure of na...

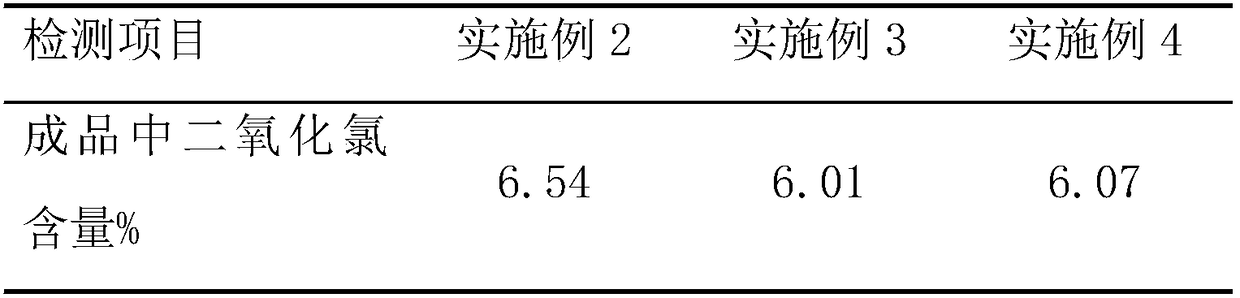

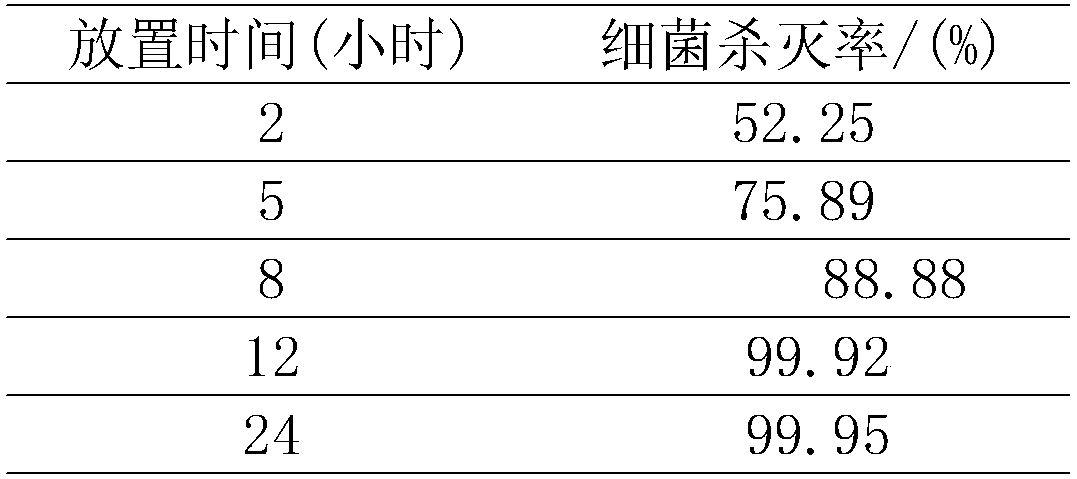

Embodiment 2

[0037] A kind of preparation method of slow release type immobilized chlorine dioxide particle is as follows:

[0038] (1) Prepare a solution containing 1000 mg / L of perfluorononoxybenzene sulfonate (OBS) and 3 mol / L of hydrochloric acid as a surfactant; soak 0.5-1mm natural zeolite at a ratio of 1:10 by weight and volume of solid to liquid After adding the surfactant to the acid solution for 1-2 hours, the acid-modified zeolite particles are obtained by suction filtration;

[0039] (2) Prepare a nitrate compound solution, which contains 0.2mol / L iron nitrate, 0.2mol / L manganese nitrate, and 0.1mol / L copper nitrate. Soak the acid-modified zeolite and the nitrate solution for 12 hours at a solid-to-liquid weight-to-volume ratio of 1:15, drain the supernatant, and roast at 500°C for 4 hours to obtain transition metal-loaded zeolite particles;

[0040] (3) Prepare coating agent. Mix sodium chlorite powder, silica gel powder and diatomaceous earth in a V-type mixer in a weight r...

Embodiment 3

[0046] A kind of preparation method of slow release type immobilized chlorine dioxide particle is as follows:

[0047] (1) Prepare a mixed solution containing surfactant sodium dodecylbenzenesulfonate, sodium dodecylsulfate, sulfuric acid, nitric acid, the concentration of sodium dodecylbenzenesulfonate is 2000mg / L, dodecylbenzenesulfonate The concentration of sodium sulfate is 1000mg / L, the concentration of sulfuric acid is 0.5mol / L, and the concentration of nitric acid is 0.5mol / L; soak 2-3mm natural zeolite in the mixed solution according to the ratio of solid-liquid weight to volume 1:15 2 hours, suction filtration to obtain acid-modified zeolite particles;

[0048] (2) Prepare a nitrate solution containing 0.1mol / L cerium nitrate, 0.2mol / L manganese nitrate, and 0.2mol / L copper nitrate, and mix the acid-modified zeolite and the nitrate solution in a ratio of 1:15 by solid-liquid weight-volume ratio After soaking for 20 hours, draining the supernatant, and roasting at 800...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com