Medical fabric

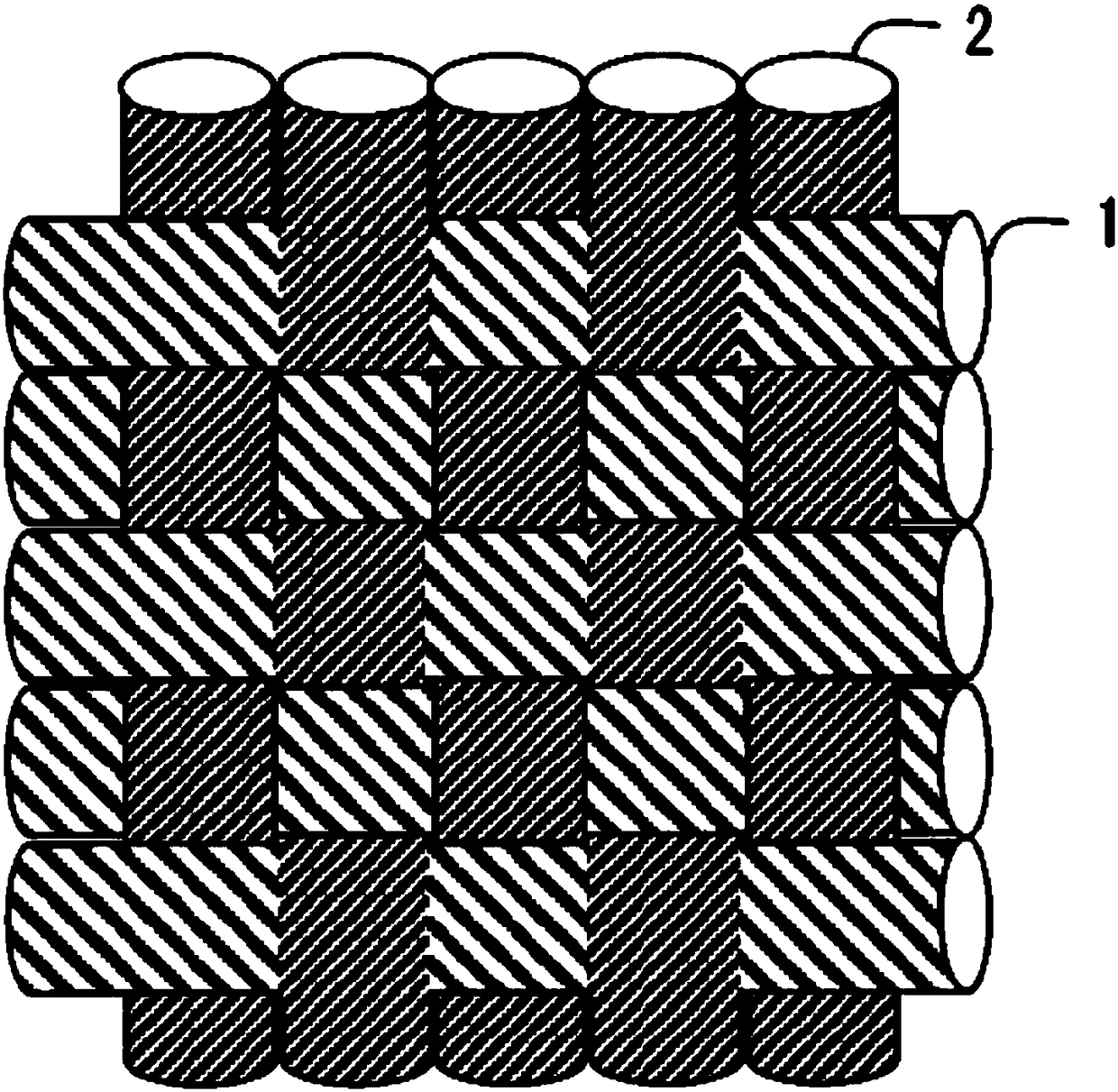

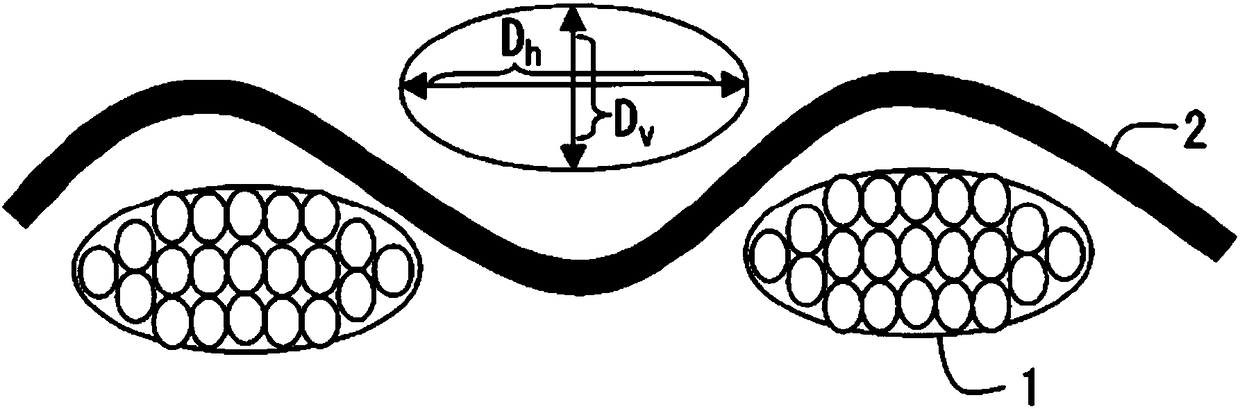

A medical and fabric technology, applied in the field of medical fabrics for implants, can solve the problems of low water permeability and tear strength, and achieve the effects of small water permeability, small diameter and thin thickness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0205]

[0206] Polyethylene terephthalate (PET) was used as a raw material, and melt spinning was performed to wind up an undrawn yarn of 65 decitex.

[0207] The properties of the raw material PET polymerized with the germanium catalyst are as follows.

[0208] Reduced viscosity (ηsp / c): 1.162dl / g

[0209] Titanium content: 2ppm

[0210] Diethylene glycol content: 0.8% by weight

[0211] Oligomer content: 1.2% by weight

[0212] The spinneret holes used were 5-layered spinneret holes with a hole diameter of 0.08 mmφ, the distance between the innermost jet nozzles was 1.7 mm, and the distance between all the rows was 8 mm. The cooling of the filaments basically used a cooling air jetting device having a jetting outlet at an elevation angle of 37°. In addition, under the spinning conditions (the surface temperature of the spinneret hole is 303°C, the temperature distribution of the spinneret hole is 3°C, the length of the hot zone is 36mm, the temperature of the cooling ai...

Embodiment 2

[0222]

[0223] Polyethylene terephthalate (PET) was used as a raw material, and melt spinning was performed to wind up an undrawn yarn of 140 decitex. Microfibers were produced under the same conditions as in Example 1.

[0224]

[0225] By the above-mentioned spinning, a total fineness of 72.4 dtex / 450 filaments was produced as a weft.

[0226] The total fineness used in the warp yarn is 34.1 dtex / 24 filaments, the appropriate spinneret holes are selected, melt spinning is performed, and the draw ratio is set to produce.

[0227]

[0228] Using a known twister, warp yarns were twisted 500 times / m (S direction twist) and weft yarns were twisted 100 times / m (S direction twist) to produce twisted yarns.

[0229]

[0230] Using the above-mentioned warp and weft, under the same conditions as in Example 1, a flat-woven tubular seamless fabric with an inner diameter of 50 mm was produced. Furthermore, scouring and heat setting are performed on this fabric to perform finis...

Embodiment 3

[0232]

[0233] Microfibers were produced under the same conditions as in Example 1.

[0234]

[0235] By the above-mentioned spinning, a total fineness of 20.1 dtex / 155 filaments was produced as a weft. Spinning was performed under the same conditions as in Example 2. As the warp, a total fineness of 34.1 decitex / 24 filaments was produced.

[0236]

[0237] Using a known twister, warp yarns were twisted 500 times / m (S direction twist) and weft yarns were twisted 100 times / m (S direction twist) to produce twisted yarns.

[0238]

[0239] Using the above-mentioned warp and weft, under the same conditions as in Example 1, a flat-woven tubular seamless fabric with an inner diameter of 50 mm was produced. Furthermore, scouring and heat setting are performed on this fabric to perform finishing. The evaluation results of the obtained fabrics are shown in Tables 1 and 2 below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com