Preparing process of high-performance TiB2/A356 composite panel

A composite material and preparation process technology, which is applied in the field of preparation technology of in-situ particle TiB2 reinforced A356 composite material sheet, can solve the problems of low bonding strength between particles and materials, uneven distribution of rolled plate structure, unstable material properties, etc. The grains are small and round, the particles are evenly dispersed, and the plasticity is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0010] TiB 2 Particle reinforced A356 composite material, its main component is: TiB 2 Particles: 2.5~3%wt, Si: 6.5~7.5%wt, Mg: 0.3~0.45%wt, Ti≤0.2%wt, Fe≤0.12%wt, Mn≤0.05%wt, Cu≤0.1%wt, Zn≤ 0.05%wt, balance Al.

[0011] Process steps: (1) Potassium fluorotitanate and potassium fluoroborate are dried and mixed evenly for later use. (2) Put the A356 alloy into a graphite crucible, heat it to 800~850°C through an induction cooker, and let it stand for 1~2min to ensure that the alloy melts. (3) Add the dried and uniformly mixed reaction powder into the molten A356 according to the weight of 8% of the matrix mass, and add the powder at one time. (4) After the reaction powder is added, stir at 800~850°C. The stirring method is: manual stirring for 2 minutes, then mechanical stirring for 10 minutes, and standing for 2 to 3 minutes. After standing, continue manual stirring for 3 minutes. Finally, stir mechanically for 4~8min, and continue to stand still for 1~2min. (5) After the...

Embodiment example 2

[0013] TiB 2 Particle reinforced A356 composite material, its main component is: TiB 2 Particles: 2.5~3%wt, Si: 6.5~7.5%wt, Mg: 0.3~0.45%wt, Ti≤0.2%wt, Fe≤0.12%wt, Mn≤0.05%wt, Cu≤0.1%wt, Zn≤ 0.05%wt, balance Al.

[0014] Process steps: (1) Potassium fluorotitanate and potassium fluoroborate are dried and mixed evenly for later use. (2) Put the A356 alloy into a graphite crucible, heat it to 800~850°C through an induction cooker, and let it stand for 1~2min to ensure that the alloy melts. (3) Add the dried and uniformly mixed reaction powder into the molten A356 according to the weight of 8% of the matrix mass, and add the powder at one time. (4) After the reaction powder is added, stir at 800~850°C. The stirring method is: manual stirring for 2 minutes, then mechanical stirring for 10 minutes, and standing for 2 to 3 minutes. After standing, continue manual stirring for 3 minutes. Finally, stir mechanically for 4~8min, and continue to stand still for 1~2min. (5) After the...

Embodiment example 3

[0016] TiB 2 Particle reinforced A356 composite material, its main component is: TiB 2 Particles: 2.5~3%wt, Si: 6.5~7.5%wt, Mg: 0.3~0.45%wt, Ti≤0.2%wt, Fe≤0.12%wt, Mn≤0.05%wt, Cu≤0.1%wt, Zn≤ 0.05%wt, balance Al.

[0017]Process steps: (1) Potassium fluorotitanate and potassium fluoroborate are dried and mixed evenly for later use. (2) Put the A356 alloy into a graphite crucible, heat it to 800~850°C through an induction cooker, and let it stand for 1~2min to ensure that the alloy melts. (3) Add the dried and uniformly mixed reaction powder into the molten A356 according to the weight of 8% of the matrix mass, and add the powder at one time. (4) After the reaction powder is added, stir at 800~850°C. The stirring method is: manual stirring for 2 minutes, then mechanical stirring for 10 minutes, and standing for 2 to 3 minutes. After standing, continue manual stirring for 3 minutes. Finally, stir mechanically for 4~8min, and continue to stand still for 1~2min. (5) After the ...

PUM

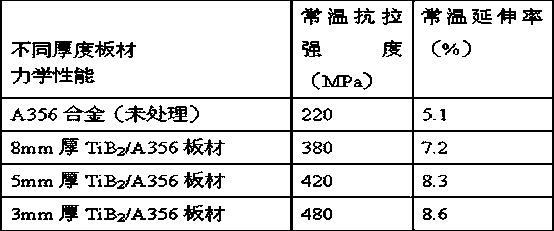

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com