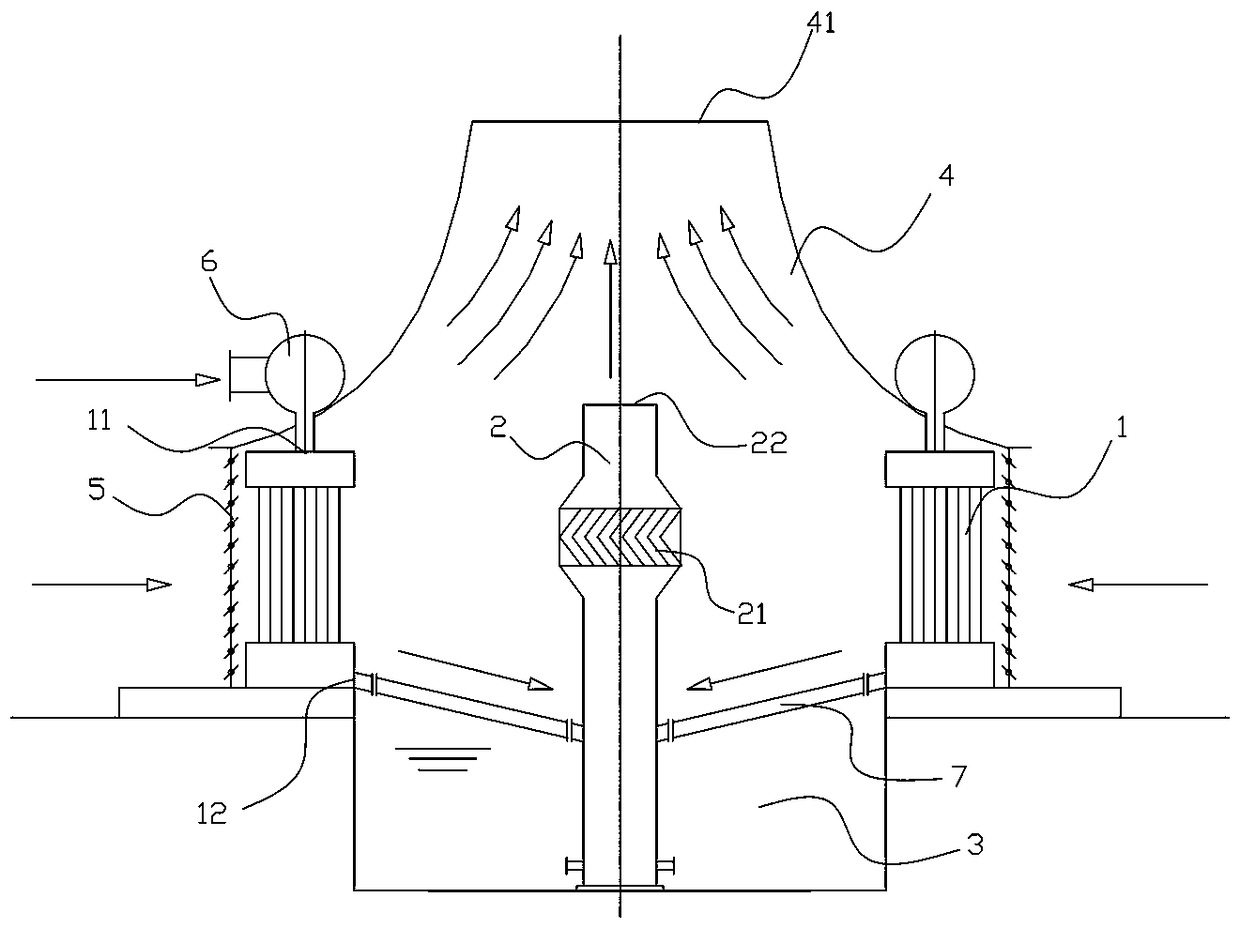

Double-curve natural ventilation, condensation, water lifting and white smoke elimination integral device

A natural ventilation and hyperbolic technology, applied in gas treatment, chemical instruments and methods, lighting and heating equipment, etc., can solve the problems of large water consumption, high cost, complex structure, etc., to avoid pollution and reduce absolute moisture content , Eliminate the effect of visual pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] In the first embodiment, the condenser 1 and the chimney 2 are provided with an air regulating baffle 5 on the side opposite to the chimney 2. By adjusting the opening of the air regulating baffle 5, the air intake of the hyperbolic ventilation tower 4 can be adjusted, thereby adjusting the water lift of the flue gas. The ventilation tower 4 extends to one side of the air regulating baffle 5, and the two ends of the air regulating baffle 5 are respectively connected with the ventilation tower 4 and the ground. The lower end of the chimney 2 extends under the liquid level in the reservoir 3 , the lower end of the chimney 2 is provided with an opening, and the opening runs through the inside of the chimney 2 and the reservoir 3 . The mist formed by the flue gas in the condenser 1 forms a liquid flow on the inner surface of the chimney 2 and the surface of the mist eliminator 21, flows or falls below the chimney 2, and enters the reservoir 3, and the liquid surface of the r...

Embodiment 2

[0028] In the second embodiment, a smoke distributor 6 is installed at the smoke inlet 11 of the condenser 1 , and the smoke passes through the smoke distributor 6 and then evenly distributes into the smoke condenser 1 . There is at least one set of deflectors inside the smoke distributor 6, and the deflectors are made of anti-corrosion materials such as carbon steel lining anti-corrosion scales or fiber-reinforced composite materials. The flue gas is cooled by the cold air in the flue gas condenser 1, the temperature drops, the water vapor condenses, and then enters the chimney 2. The resistance of the condenser 1 can be controlled by the flue gas flow rate. The diameter of the heat exchange tube of the condenser 1 is within Between 30-40mm, adjusting the pipe diameter can change the flue gas flow rate, and the flue gas flow rate in the pipe is 10-15 m / s. The cold air in the external environment passes through the condenser 1 after passing through the air regulating baffle 5,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com