Hydraulic jacking mechanism for liquid weighing container

A jacking mechanism and container technology, applied in fluid pressure actuation devices, weighing equipment testing/calibration, weighing equipment with special properties/forms of materials, etc., can solve the problem of affecting the measurement error of electronic scales and reduce electronic scales Problems such as service life and impact damage of weighing sensors can be solved to achieve the effect of improving verification accuracy, simple structure and low failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below with reference to the accompanying drawings.

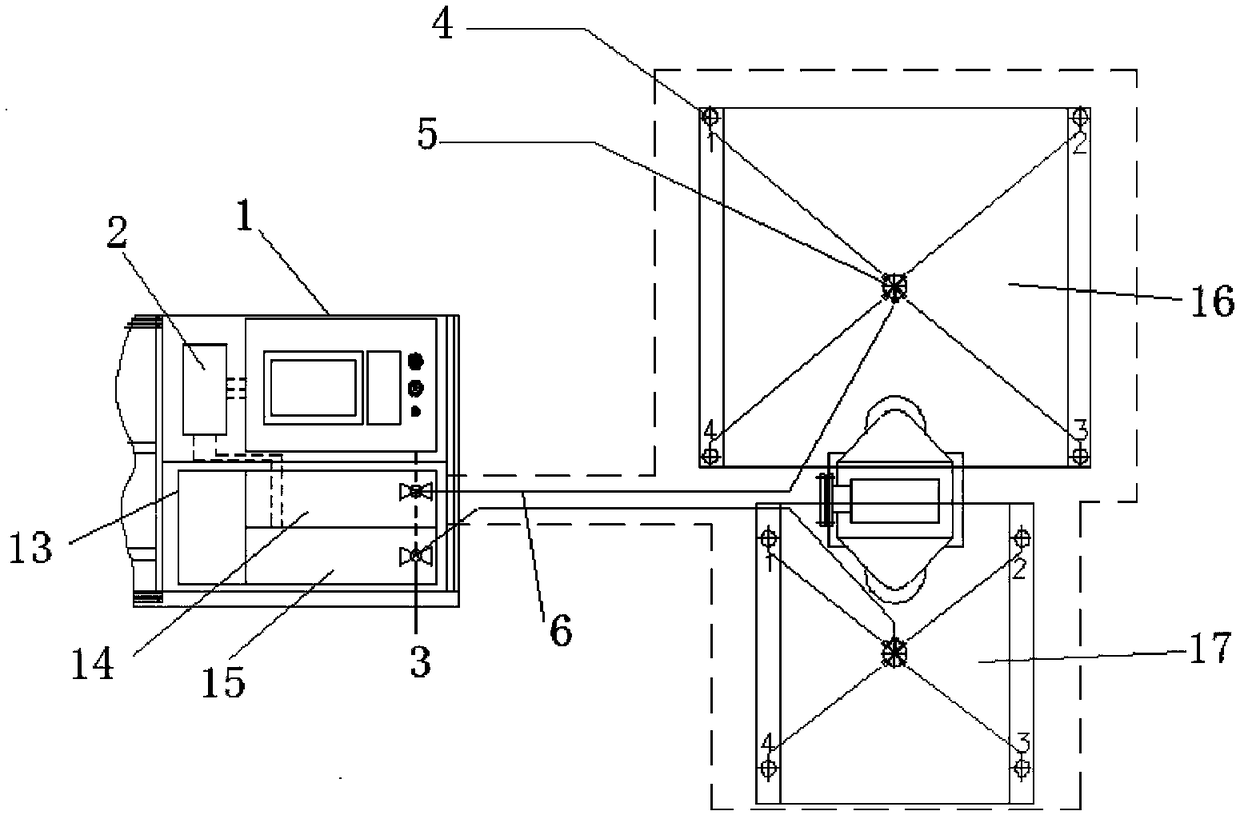

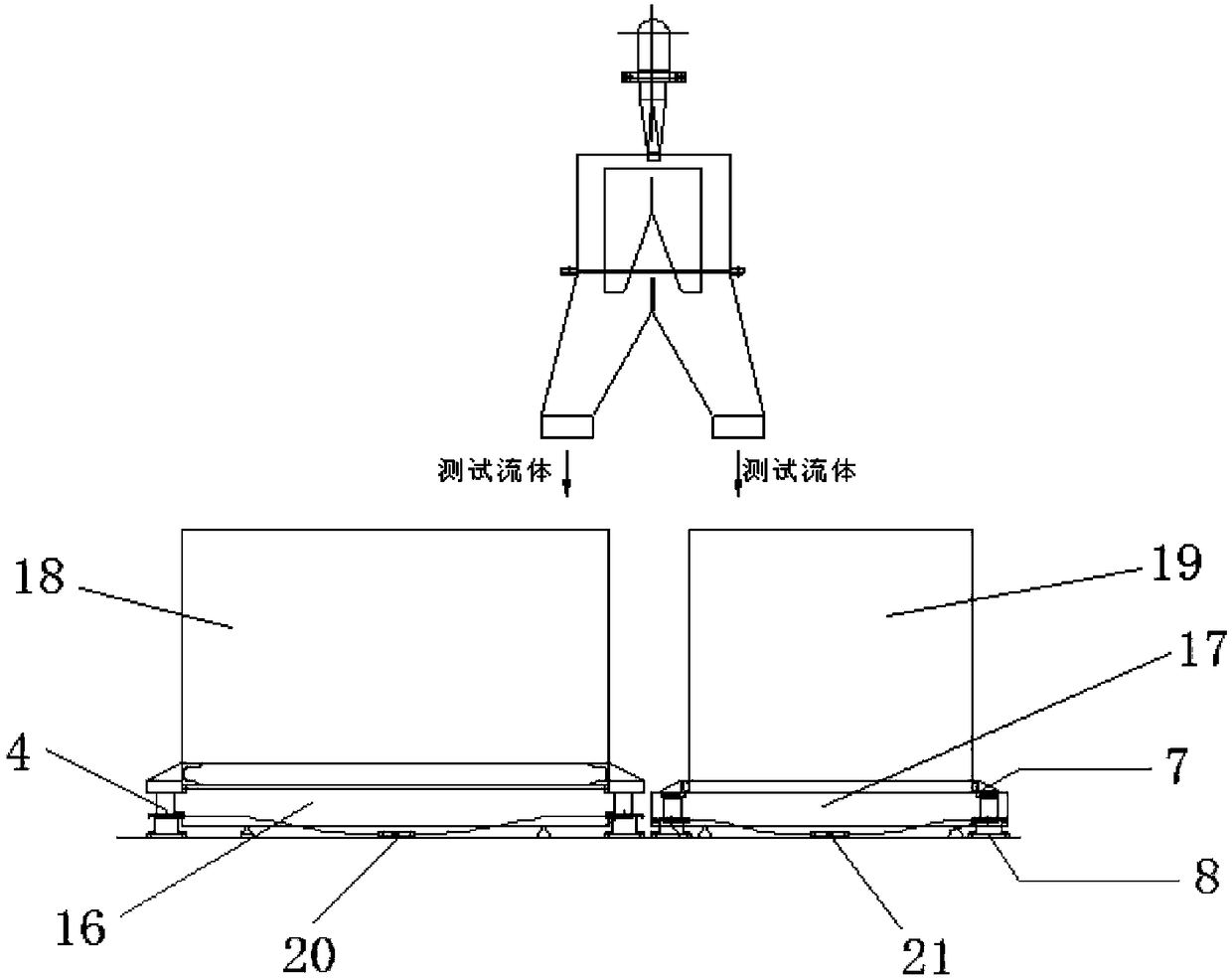

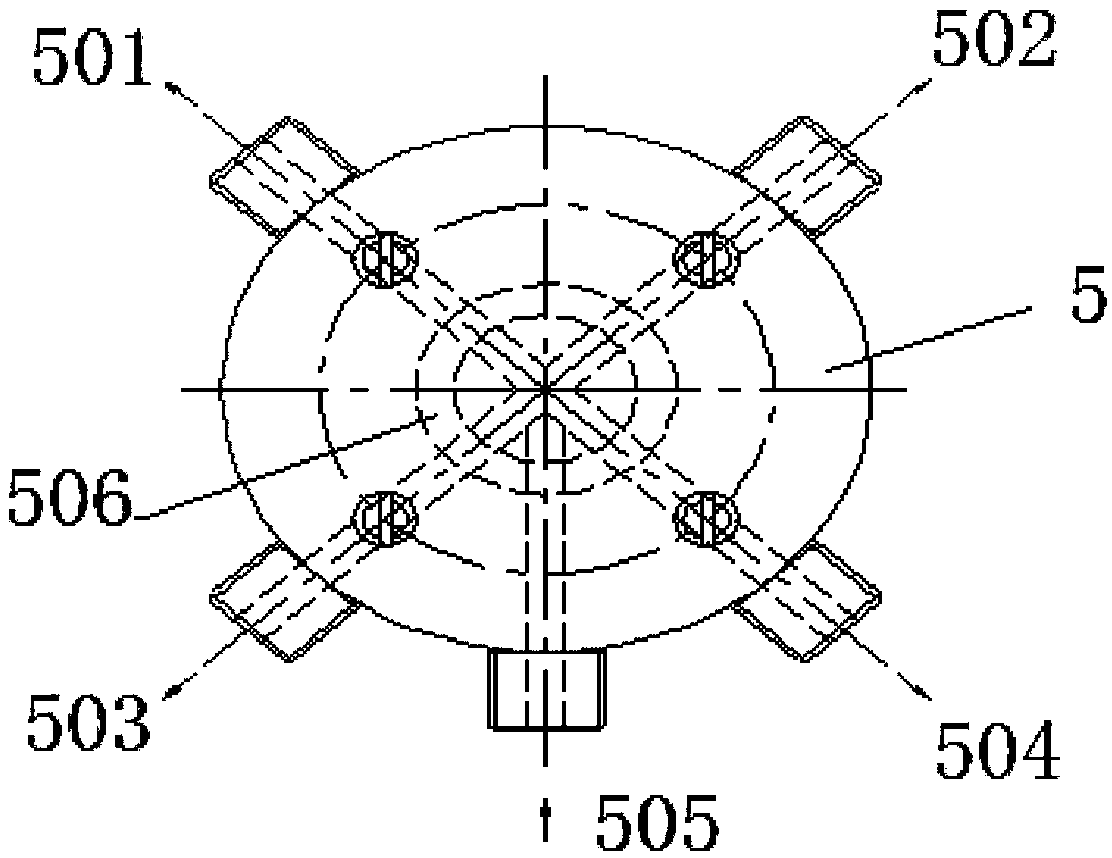

[0025] like figure 1 , 2 As shown, a hydraulic jacking mechanism for a liquid weighing container of the present invention includes a hydraulic system, a separate jack 4, a container skid 7 and a hydraulic synchronizing distributor 5, wherein the container skid is fixed at the bottom of the weighing container, A plurality of separate jacks are installed at the bottom of the container skid, and each separate jack is fixed on the ground through the jack fixing base 8; the hydraulic pipeline of the hydraulic system is connected with the hydraulic cylinder of each separate jack through the hydraulic synchronizing distributor; the electronic scale is located in Between the bottom of the container skid base and the fixed bases 8 of the separate jacks, the weighing container is separated and attached to the electronic scale under the action of the hydraulic cylinders of the sep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com