Synchronous powder spreading type metal laser 3D printing powder feeding device

A technology of 3D printing and powder feeding device, which is applied in the field of laser 3D printing, can solve problems such as the disturbance of molten pool liquid level and the influence of cladding layer structure, so as to improve the utilization rate of powder, improve the consistency and directionality of the structure, Eliminates the effects of shocks and disturbances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing, the present invention is described in further detail:

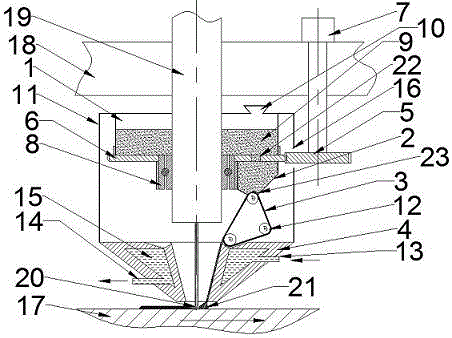

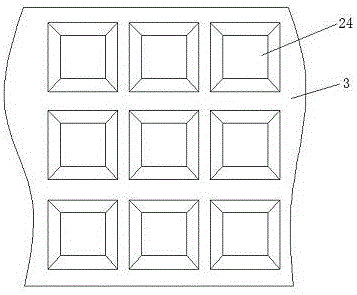

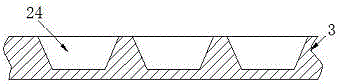

[0022] The structure of a powder feeding device for synchronous powder-spreading metal laser 3D printing in this embodiment is as follows: figure 1 As shown, it includes a powder storage bin 1, a powder feeding bin 2, a powder feeding belt 3, a powder spreading head 4, a main transmission gear 5, a slave transmission gear 6, a driving motor 7, a beam 18, a cladding head 19 and a casing 11.

[0023] In this embodiment, the metal powder 9 is Inconel 625 superalloy powder, which is spherical and has a particle size of 40-100 μm. A sample with a size of 50mm×50mm×50mm is prepared by laser 3D printing. The scanning path adopts an "S" shape, the laser spot diameter is 3mm, the overlap rate is 50%, the scanning speed is 300mm / min, and the laser power is 1000W.

[0024] Such as figure 1 As shown, the metal powder 9 is loaded into the powder storage bin 1 from the powder inl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com