Catalytically cracked oil slurry furfural extracted oil hydrogenation catalyst, and preparation method and applications thereof

A technology for catalytic cracking of oil slurry and furfural extraction of oil, which is applied in physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve problems such as no extraction of oil, and achieve high hydrodesulfurization and active metal utilization. , the effect of large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

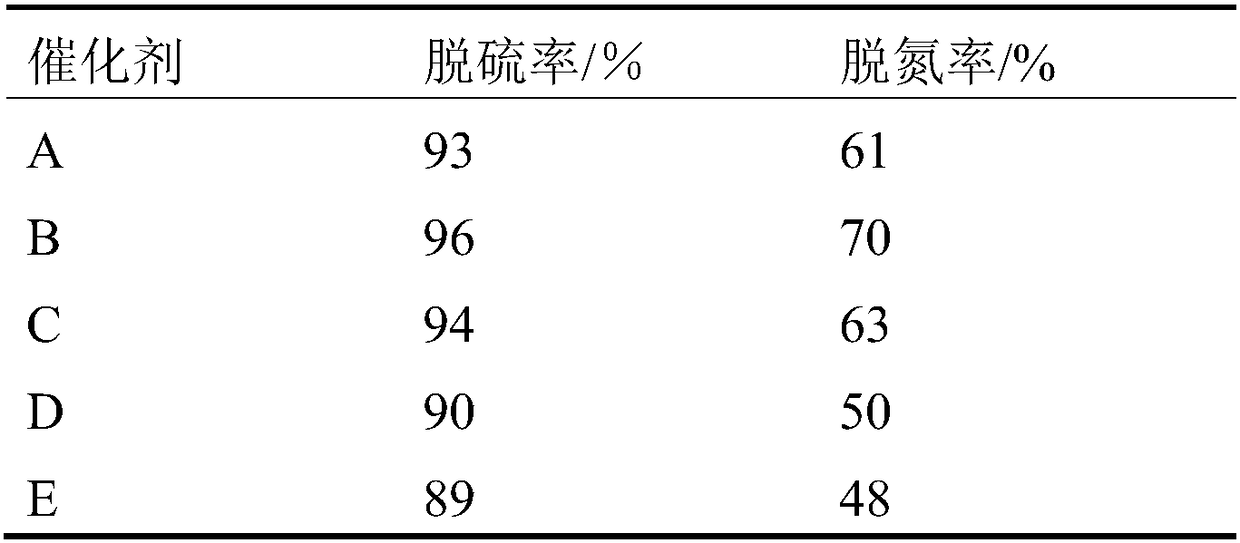

Embodiment 1

[0033]Take 100g of pseudoboehmite, 11.2g of TS-1 molecular sieve, 1.4g of zirconia, and 1.4g of graphene, and mix them evenly. Add 2.8g of scallop powder, mix evenly, dropwise add an aqueous solution containing 2.8g of nitric acid and 2.8g of citric acid, knead, extrude into a clover shape of 1.5mm, freeze-dry, and then roast at 550°C for 4h to make a carrier. Reuse Mn 6 [WMn 3 (H 2 O) 2 (ZnW 9 o 34 ) 2 ] The prepared impregnating solution was impregnated with equal volume (see Table 1 for the amount of active components supported in the catalyst), freeze-dried, and calcined at 300°C for 6h to obtain catalyst A.

Embodiment 2

[0035] Take 100g of pseudoboehmite, 105g of TS-1 molecular sieve, 35g of zirconia, and 17.5g of graphene, and mix them evenly. Add 17.5g of scallop powder, mix evenly, add dropwise an aqueous solution containing 17.5g of nitric acid and 17.5g of citric acid, knead, extrude into a clover shape of 1.5mm, freeze-dry, and then roast at 550°C for 4h to make a carrier. Reuse Co 6 [WCo 3 (H 2 O) 2 (ZnW 9 o 34 ) 2 ] The prepared impregnating solution was impregnated with equal volume (see Table 1 for the amount of active components supported in the catalyst), freeze-dried, and calcined at 300° C. for 5 h to obtain catalyst B.

Embodiment 3

[0037] Take 100g of pseudoboehmite, 35g of TS-1 molecular sieve, 12.25g of zirconia, and 5.25g of graphene, and mix them evenly. Add 7g of scallop powder, mix evenly, dropwise add an aqueous solution containing 7g of nitric acid and 7g of citric acid, knead, extrude into a clover shape of 1.5mm, freeze-dry, and then roast at 550°C for 4h to make a carrier. Use Ni again 6 [WNi 3 (H 2 O) 2 (ZnW 9 o 34 ) 2 ] The prepared impregnating solution was impregnated with equal volume (see Table 1 for the amount of active components supported in the catalyst), freeze-dried, and calcined at 550°C for 2h to obtain catalyst C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com