Aqueous sodium ion battery na 0.58 mn 2 o 4 1.38h 2 oMaterials and their preparation methods and applications, electrodes

A na0.58mn2o4·1.38h2o, sodium ion battery technology, applied in battery electrodes, secondary batteries, active material electrodes, etc., to achieve the effect of low cost, simple process and good controllability of conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

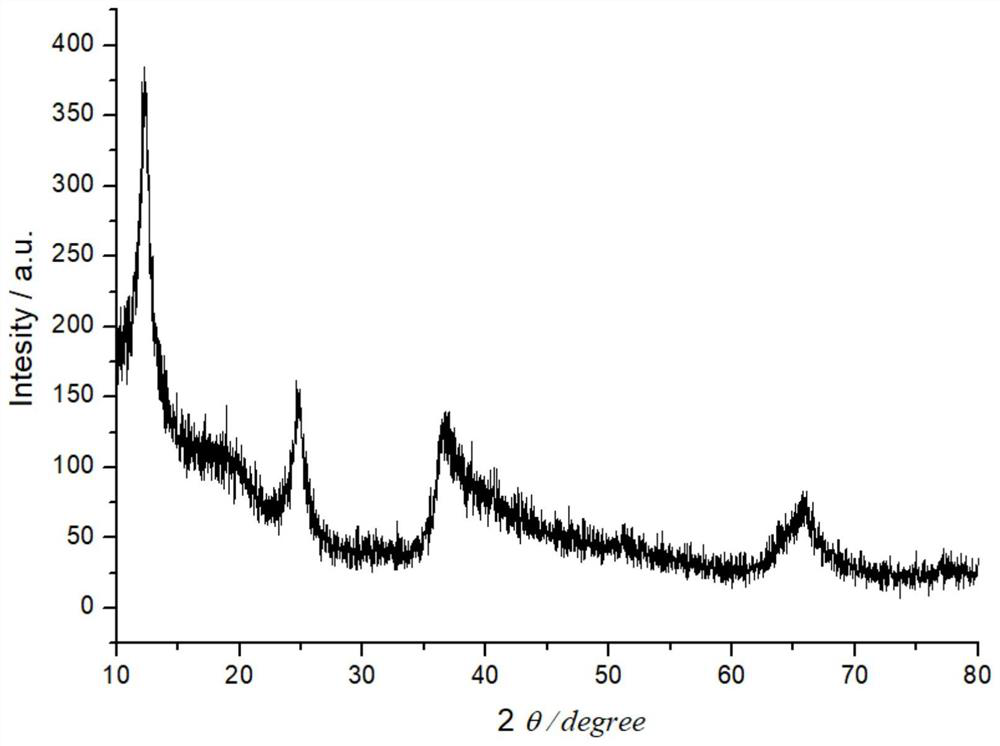

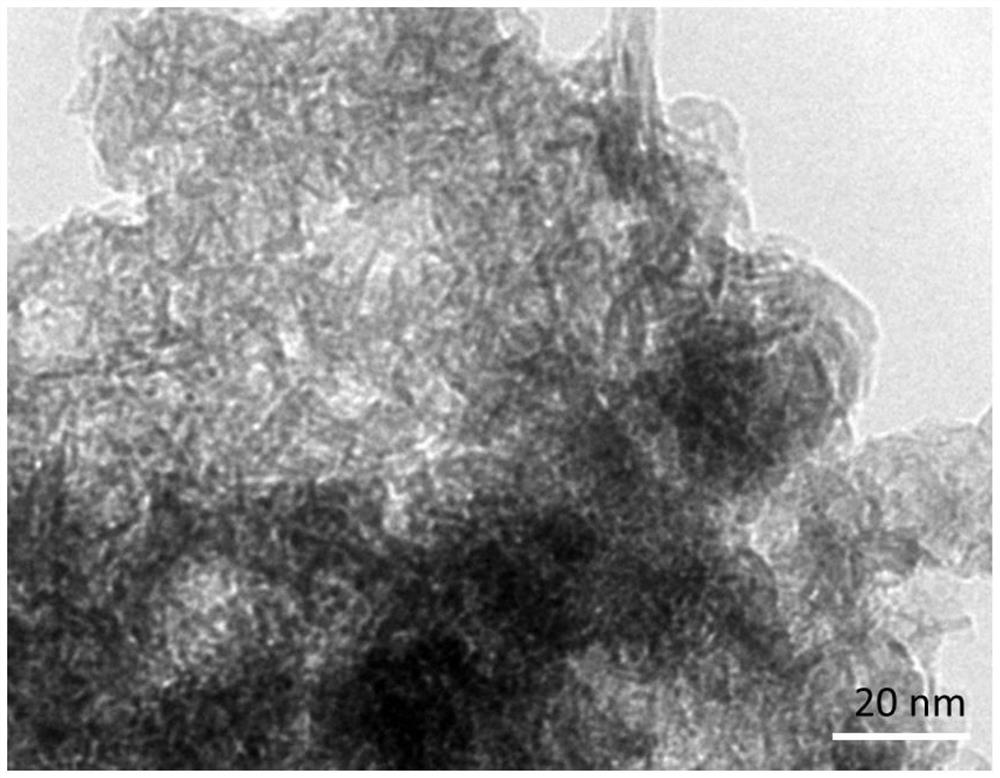

[0025] The aqueous sodium ion battery Na of the embodiment of the present invention 0.58 mn 2 o 4 1.38H 2 The O material is the flower-like Na 0.58 mn 2 o 4 1.38H 2 O material. The preparation method may include, for example, the following steps: mixing potassium permanganate solution, divalent manganese salt and carbon quantum dot mixed solution, collecting the precipitate, soaking in the soaking solution, separating, collecting the solid, and obtaining the positive electrode material of the aqueous sodium ion battery Flower Na 0.58 mn 2 o 4 1.38H 2 O material.

[0026] Wherein, the soaking solution includes a mixture of NaOH and alcohol and water. Soak in the soaking solution to play the role of ion exchange, so as to obtain Na through the method of low temperature redox combined with ion exchange 0.58 mn 2 o 4 1.38H 2 O material.

[0027] In the embodiment of the present invention, the mixed solution of potassium permanganate solution, divalent manganese sa...

Embodiment 1

[0039] Configuration A solution: 0.1mol / L potassium permanganate solution; B solution: 0.1mol / L manganese chloride + 1mg / mL carbon quantum dot solution.

[0040] Under the stirring condition of 500r / min, add solution B dropwise to 50mL of solution A, the mass ratio of potassium permanganate in solution A, divalent manganese salt in solution B and carbon quantum dots is 10:20:1 in turn, half an hour finished adding.

[0041] The precipitate obtained by the reaction was cleaned by suction filtration and soaked in a mixed solution of NaOH propanol and water for 24 hours, centrifuged at 2000r / min for 3min, washed and dried to obtain an aqueous sodium ion battery Na 0.58 mn 2 o 4 1.38H 2 O material.

Embodiment 2

[0043] The difference between this embodiment and embodiment 1 is: the divalent manganese salt in the B solution is the MnSO of 0.1mol / L 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com