Molybdenum disulfide/carbon composite hydrogen evolution electro-catalyst and preparation method thereof

A technology of molybdenum disulfide and carbon composite materials, which is applied in the field of electrocatalytic hydrogen evolution, can solve the problems of reducing the number of active sites and electrocatalytic activity, limiting charge transfer and kinetics, and poor conductivity of molybdenum disulfide, achieving uniform size, The effect of regular shape and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Preparation of carbon: Dissolve 0.40 g of zinc acetate and 50 g of dimethylimidazole in 200 mL of deionized water respectively, mix the above two solutions and stir at room temperature for 1 h, separate the solid, and obtain the metal organic framework material ZIF -8. Gained ZIF-8 powder was loaded into a porcelain boat, and then transferred to a temperature-programmed tube furnace. Under the protection of argon, the o C / min heat up to 750 o C and keep warm for 3 h. After naturally cooling to room temperature, a black powder was obtained, which was washed with 35% HCl, deionized water, and dried to obtain a carbon material.

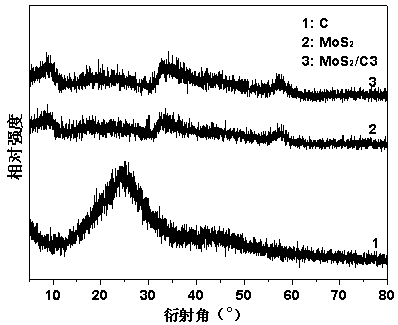

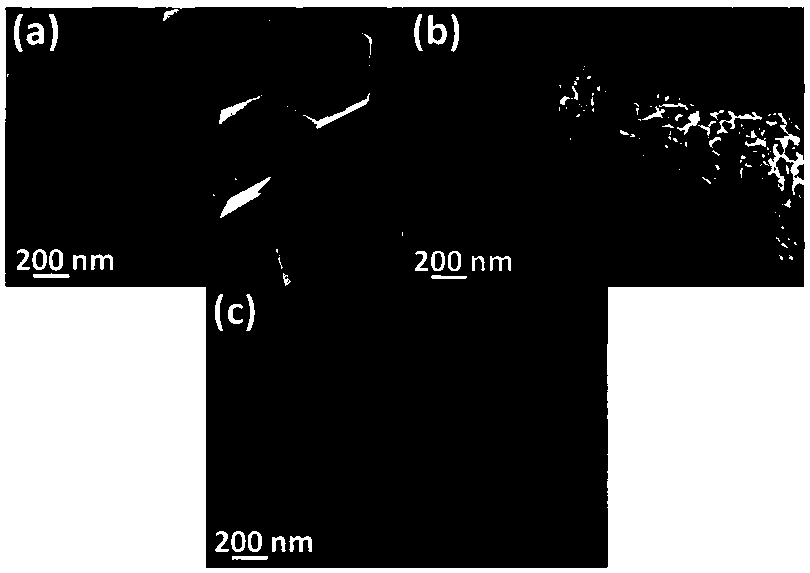

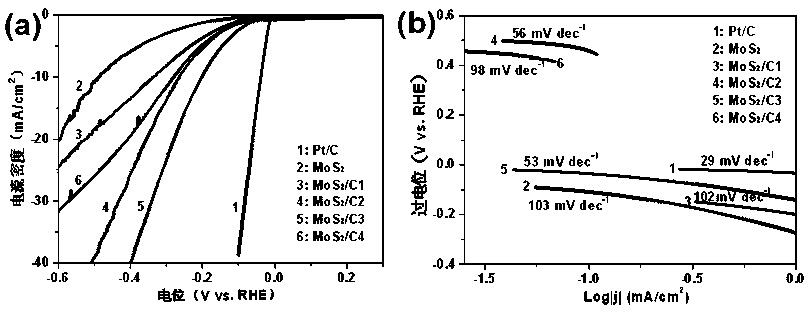

[0025] (2) Preparation of molybdenum disulfide / carbon composites by hydrothermal method: Dissolve 150 mg sodium molybdate tetrahydrate and 310 mg thiourea in 25 mL deionized water, pour the solution into a 50 mL reaction kettle, and then add 10 mg of carbon prepared in step (1), mix well, and seal. at 180 o C hydrothermal reaction for 48 ...

Embodiment 2

[0027] (1) Carbon preparation: 1.20 g of zinc sulfate and 16 g of dimethylimidazole were dissolved in 200 mL of deionized water, respectively, and the above two solutions were mixed and stirred at room temperature for 1 h to prepare the metal organic framework material ZIF-8. Gained ZIF-8 powder was loaded into a porcelain boat, and then transferred to a temperature-programmed tube furnace. Under the protection of argon, the o C / min heating up to 850 o C and keep warm for 0.5 h. After naturally cooling to room temperature, a black powder was obtained, which was washed with 35% HCl, deionized water, and dried to obtain a carbon material.

[0028] (2) Preparation of molybdenum disulfide / carbon composites by hydrothermal method: Dissolve 150 mg sodium molybdate tetrahydrate and 310 mg thiourea in 25 mL deionized water, pour the solution into a 50 mL reaction kettle, and then add 25 mg of carbon prepared in step (1), mix well, and seal. at 200 o C hydrothermal reaction for 24 ...

Embodiment 3

[0030] (1) Carbon preparation: 0.72 g of zinc nitrate and 30 g of dimethylimidazole were dissolved in 200 mL of deionized water, respectively, and the above two solutions were mixed and stirred at room temperature for 1 h to prepare the metal organic framework material ZIF-8. Gained ZIF-8 powder was loaded into a porcelain boat, and then transferred to a temperature-programmed tube furnace. Under the protection of argon, the o C / min heating up to 800 o C and keep warm for 1 h. After naturally cooling to room temperature, a black powder was obtained, which was washed with 35% HCl, deionized water, and dried to obtain a carbon material.

[0031] (2) Preparation of molybdenum disulfide / carbon composites by hydrothermal method: Dissolve 150 mg sodium molybdate tetrahydrate and 310 mg thiourea in 25 mL deionized water, pour the solution into a 50 mL reaction kettle, and then add 50 mg of carbon prepared in step (1), mix well, and seal. at 200 o C hydrothermal reaction for 24 h,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com