Synthesis method of lithium ion battery composite cathode material LiMn1-xFexPO4/C

A composite cathode material, lithium ion battery technology, applied in battery electrodes, positive electrodes, secondary batteries, etc., can solve problems such as poor performance, achieve short lithium ion diffusion paths, high packing density, and improve energy density and rate. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

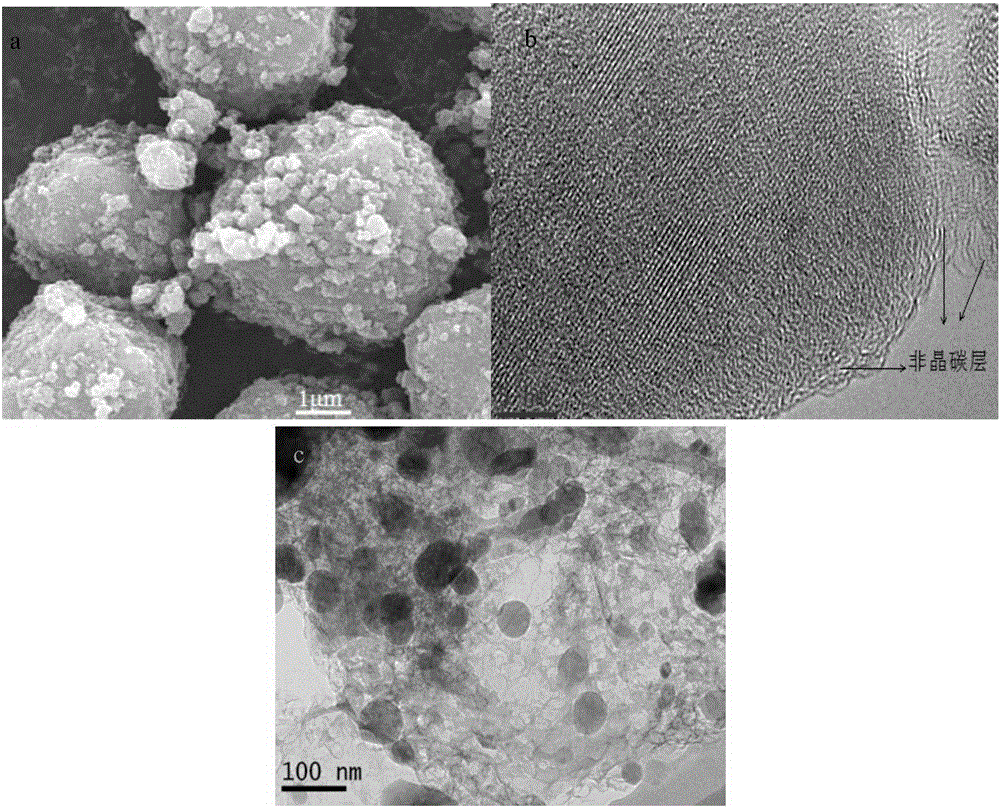

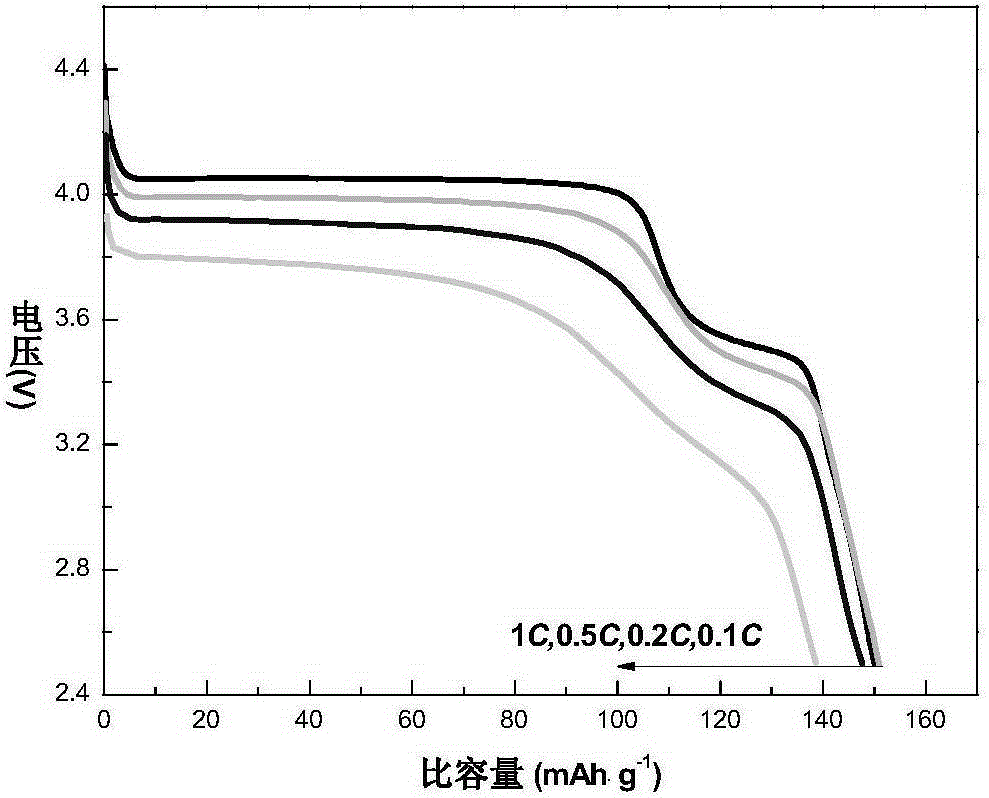

[0028] Weigh trimanganese tetroxide, ferric iron tetroxide and ammonium dihydrogen phosphate according to the Mn:Fe:P molar ratio of 0.8:0.2:1, and add 5wt% polyvinyl alcohol of the product material, mix through octagonal ball milling for 4h, and rotate at 100r / min. The mixture was reacted at 600°C for 5 h under the protection of argon atmosphere to obtain a gray product. Then the mechanically pulverized gray pyrophosphate, lithium carbonate and superconducting carbon were mixed in proportion, wherein Li:P molar ratio was 1:1 to weigh lithium carbonate, and the superconducting carbon was added in an amount of 1.5wt% of the product. Place in a high-speed fusion machine and mix for 3 hours at a speed of 700r / min. Then it was calcined at 650 °C for 8 h under the protection of argon and cooled to room temperature to obtain LiMn 0.8 Fe 0.2 PO 4 / C composite cathode material (XRD figure sees embodiment figure 1 a, topography see embodiment figure 2 a, 2b). It can be seen fr...

Embodiment 2

[0030] Manganese ferrite (MnFe 2 o 4 ), diammonium hydrogen phosphate is weighed according to (Mn+Fe):P molar ratio 1:1, and the polypropylene of product 3wt% is added, mixes and disperses in the ball mill jar of planetary ball mill, passes through planetary ball mill ball mill 2h, rotating speed 400r / min, to obtain the precursor mixture. The mixture was reacted at 650 ° for 8h under the protection of argon atmosphere to obtain (Mn 1 / 3 Fe 2 / 3 ) 2 P 2 o 7 / C pyrophosphate precursor. Then the pyrophosphate precursor, lithium hydroxide and sucrose were mixed in proportion, Li:P molar ratio was 1:1 to weigh lithium hydroxide, and the added amount of sucrose was 7wt% of the product. Place in a high-speed mixer and mix for 5 hours at a speed of 1000r / min. Then it was calcined at 750 °C for 6 h under the protection of argon and cooled to room temperature to obtain LiMn 1 / 3 Fe 2 / 3 PO 4 / C composite cathode material. It is detected that the composite positive electrode mat...

Embodiment 3

[0032] Ammonium phosphate, manganese dioxide, and ferric oxide were weighed according to the Mn:Fe:P molar ratio of 0.9:0.1:1, and 9 wt% phenolic resin was added to the product material, mixed and passed through a V-type mixing ball mill for 3 hours at a speed of 200r / min. The mixture was reacted at 550 ° for 6h under the protection of argon atmosphere to obtain a gray (Mn 0.9 Fe 0.1 ) 2 P 2 o 7 / C, to detect the XRD structure see the embodiment figure 1 b. Then gray pyrophosphate, lithium carbonate and polypropylene are mixed in proportion, wherein Li:P molar ratio is 1:1 to weigh lithium carbonate, and the addition amount of polypropylene is 15wt% of the product. Place in a high-speed mixer and mix for 6 hours at a speed of 700r / min. Then calcined at 600 °C for 4 h under the protection of argon and cooled to room temperature to obtain LiMn 0.9 Fe 0.1 PO 4 / C composite positive electrode material (topographical figure sees embodiment figure 2 c). SEM shows that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com