Wet-method recycling and harmless treatment process for antimony smelting arsenic alkali residue

A technology of harmless treatment and arsenic-alkali slag, applied in the direction of alkali metal compounds, process efficiency improvement, inorganic chemistry, etc., can solve the problems of easy blockage of equipment pipelines, landfill in another site, and high production costs, and achieves a solution Pipes and valves are easy to block, improve metal recovery and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

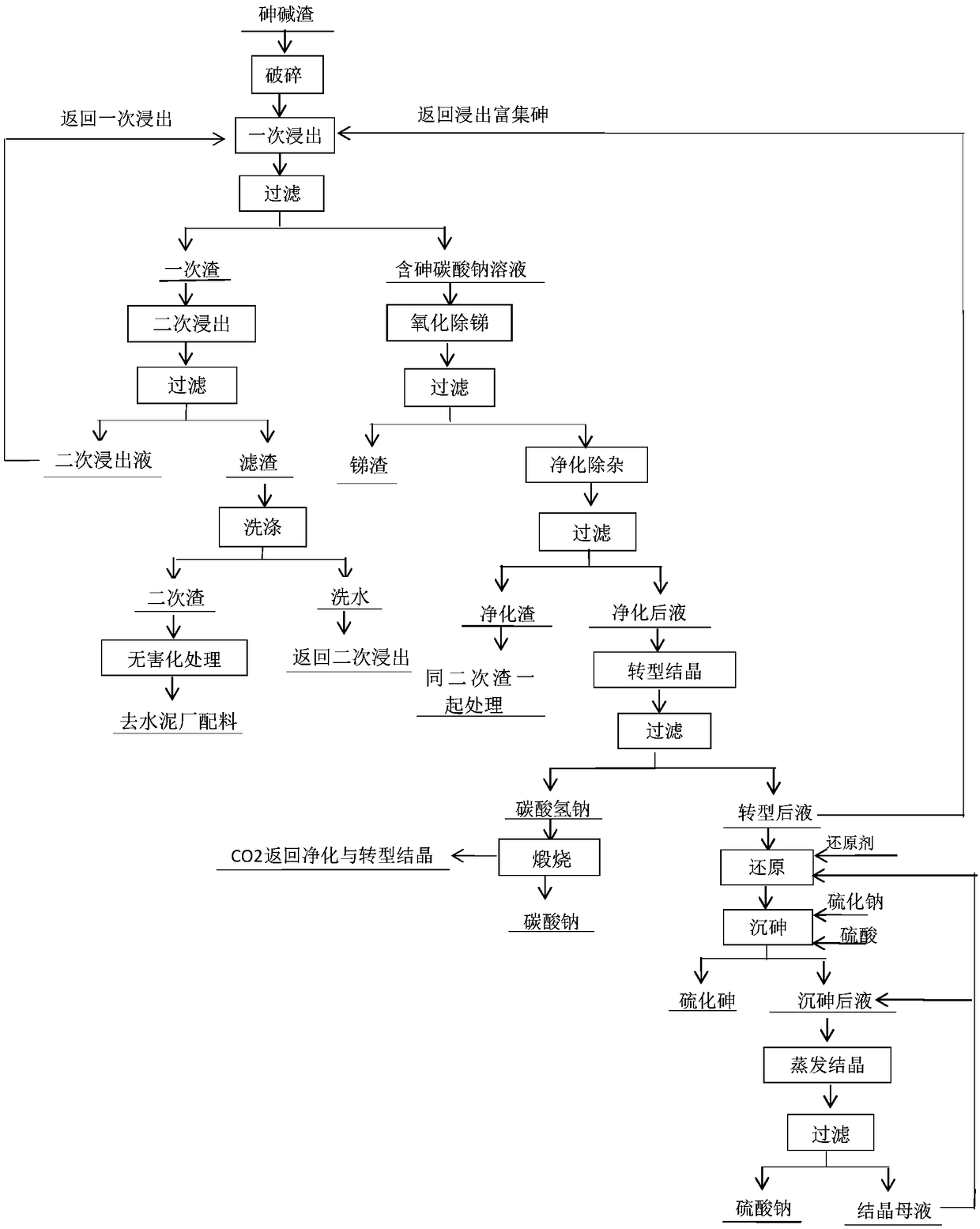

[0072] The wet recycling and harmless treatment process of antimony smelting arsenic-alkali slag, the process specifically includes the following steps:

[0073] (1) Crushing: crush the arsenic-alkali slag from different antimony smelting companies, and the particle size after crushing is less than 100 mesh;

[0074] (2) Dissolution and leaching: the arsenic-alkali slag is leached by two-stage countercurrent water leaching:

[0075] i. According to the liquid-solid ratio of water and arsenic-alkali slag of 3:1 for primary leaching, leaching at 70°C for 3 hours to ensure that the leaching slag has good filtration performance, and obtain primary slag and arsenic-containing sodium carbonate solution after filtration; The primary slag continues to be leached for the second time, and the arsenic-containing sodium carbonate solution goes to the next process to continue processing;

[0076] ii. Secondary leaching: according to the liquid-solid ratio of water and primary residue of 1...

Embodiment 2

[0085] The wet recycling and harmless treatment process of antimony smelting arsenic-alkali slag, the process specifically includes the following steps:

[0086] (1) Crushing: crush the arsenic-alkali slag from different antimony smelting companies, and the particle size after crushing is less than 100 mesh;

[0087] (2) Dissolution and leaching: the arsenic-alkali slag is leached by two-stage countercurrent water leaching:

[0088] i. According to the liquid-solid ratio of water and arsenic-alkali slag of 3.6:1 for primary leaching, leaching at 75°C for 4 hours to ensure that the leaching slag has good filtration performance, and obtain primary slag and arsenic-containing sodium carbonate solution after filtration; The primary slag continues to be leached for the second time, and the arsenic-containing sodium carbonate solution goes to the next process to continue processing;

[0089] ii. Secondary leaching: According to the liquid-solid ratio of water and primary residue of...

Embodiment 3

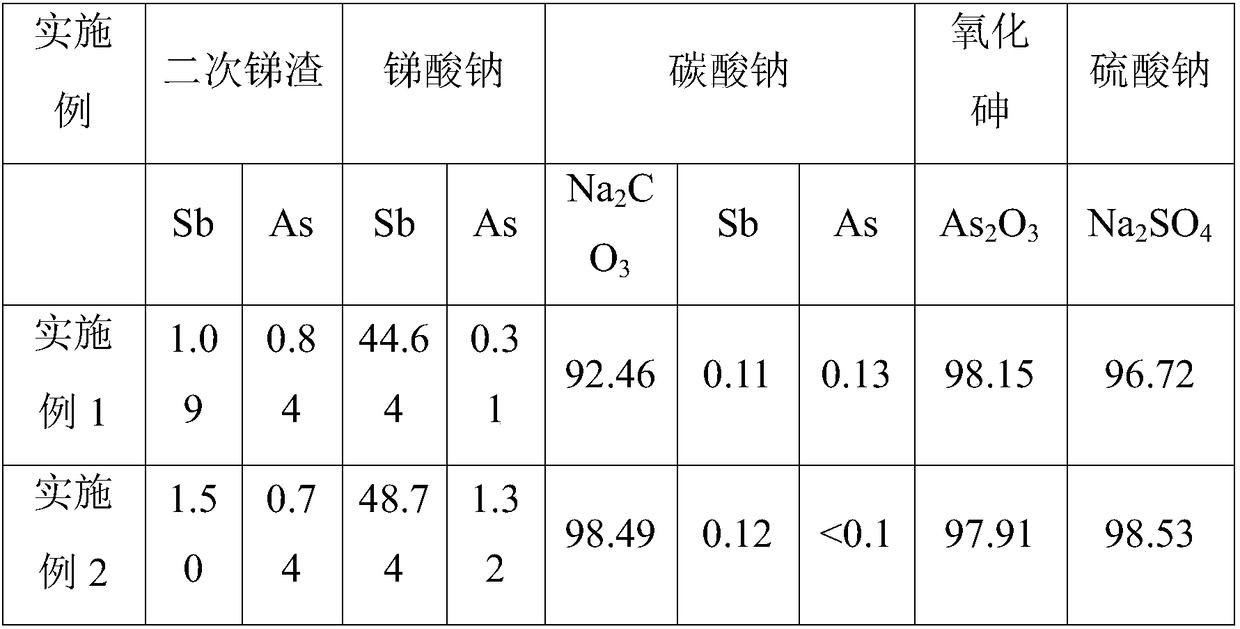

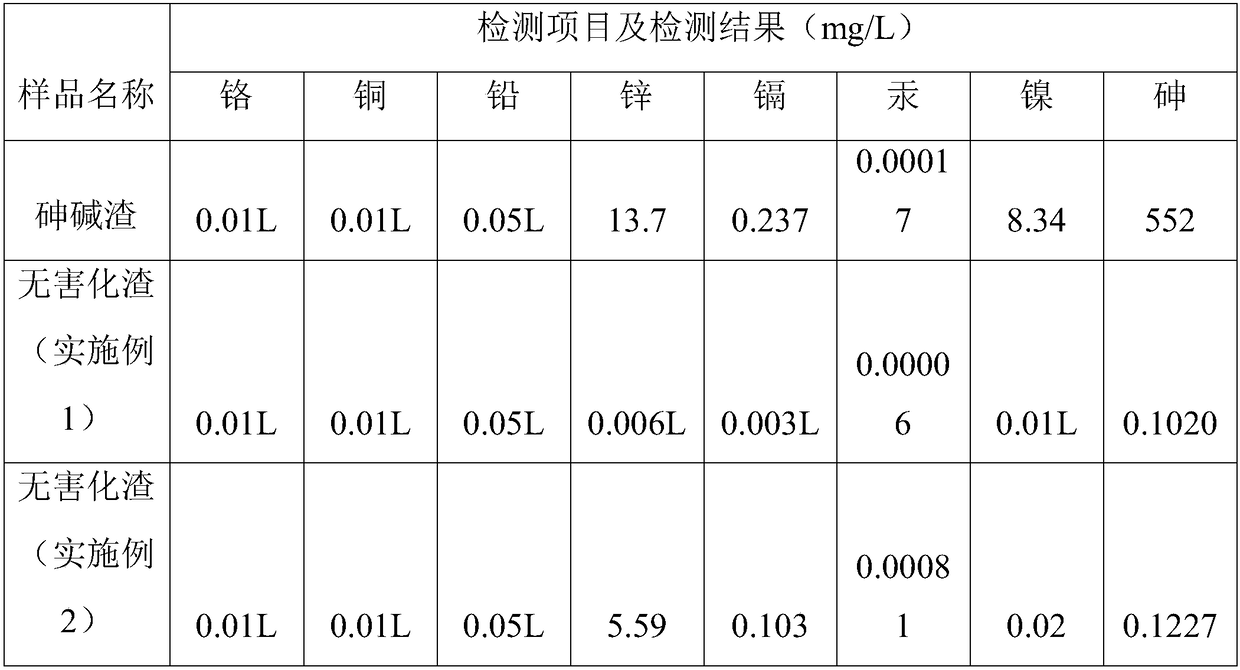

[0098] According to the processing technology of embodiment 1 and embodiment 2 to antimony smelting arsenic-alkali slag, the secondary antimony slag after step (2) dissolving and leaching, the sodium antimonate after step (3) oxidizing antimony, step (5) Substance contents such as the sodium carbonate obtained by the sodium bicarbonate calcining after transformation crystallization, step (7) gained sodium sulfate are detected, and detection result is as shown in table 1:

[0099] Table 1. Substance content (%) in the wet recycling and harmless treatment process of arsenic-alkali slag from antimony smelting

[0100]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com