Preparation technology of papaya fermented vinegar

A preparation process and technology of fermented vinegar, which is applied in the processing of papaya vinegar and the field of preparation process of papaya fermented vinegar, can solve the problems of flavor deterioration, low nutritional value of papaya vinegar, oxidative browning, etc., and achieve strong and soft vinegar taste, Resistant to oxidative browning, helps digestion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A preparation process of papaya fermented vinegar, comprising the following steps:

[0027] (1) Take the papaya raw material, remove the residual fruit, remove the core, add water at a ratio of 1.5g:1mL, squeeze the juice with a colloid mill, and obtain papaya juice with a moisture content of 85.3%, and inoculate it with wine at a ratio of 0.3g / 100ml Active dry yeast, stirred evenly, left to ferment, the fermentation temperature is 28°C, the fermentation time is 3 weeks, after the fermentation is completed, the lees are filtered to obtain papaya fruit wine;

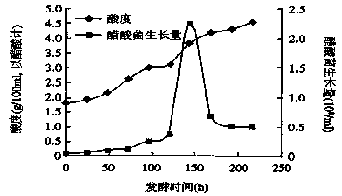

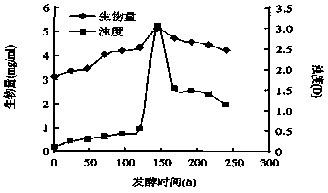

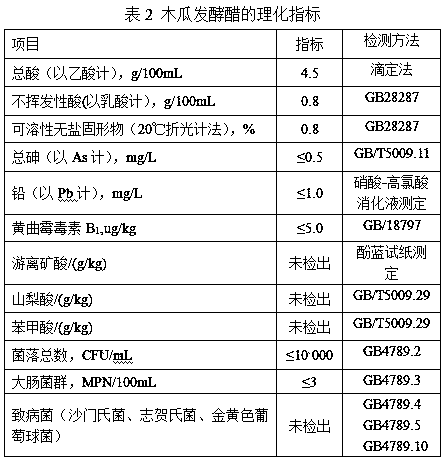

[0028] (2) Take the papaya fruit wine obtained in step (1), adjust the alcohol content to 2.3%, adjust the acidity to 1.5g / 100mL, inoculate the secondary culture solution of acetic acid bacteria according to the proportion of 5% of its volume ratio, carry out shaking table fermentation, shake The bed speed is 160r / min, the fermentation temperature is 24°C, and the total acid of the fermentation broth is measured ev...

Embodiment 2

[0039] A preparation process of papaya fermented vinegar, comprising the following steps:

[0040] (1) Take the papaya raw material, remove the residual fruit, remove the core, add water at a ratio of 1.5g:1mL, and squeeze the juice with a colloid mill to obtain papaya juice with a water content of 85.3%, and inoculate it with wine at a ratio of 0.3g / 100ml Active dry yeast, stirred evenly, left to ferment, fermentation temperature 28 ℃, fermentation time 4 weeks, after the fermentation is completed, filter the lees to get papaya fruit wine;

[0041] (2) Take the papaya fruit wine obtained in step (1), adjust the alcohol content to 4.7%, adjust the acidity to 2.3 g / 100mL, inoculate the secondary culture solution of acetic acid bacteria according to the proportion of 21% of its volume ratio, carry out shaking table fermentation, shake The bed speed is 240r / min, the fermentation temperature is 38°C, and the total acid of the fermentation broth is measured every 24h. When the tota...

Embodiment 3

[0045] A preparation process of papaya fermented vinegar, comprising the following steps:

[0046](1) Take the papaya raw material, remove the residual fruit, remove the core, add water at the ratio of 1.5g:1mL, after the juice is squeezed by the colloid mill, the water content of the papaya juice is 85.3%, inoculate the wine with high Active dry yeast, stirred evenly, left to ferment, fermentation temperature 28 ℃, fermentation time 4 weeks, after the fermentation is completed, filter the lees to get papaya fruit wine;

[0047] (2) Take the papaya fruit wine obtained in step (1), adjust the alcohol content to 4.7%, adjust the acidity to 1.8 g / 100mL, inoculate the secondary culture medium of acetic acid bacteria according to the proportion of 11% of its volume ratio, carry out shaking table fermentation, shake The bed speed is 200r / min, the fermentation temperature is 35°C, and the total acid of the fermentation broth is measured every 24h. When the total acid is constant, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com