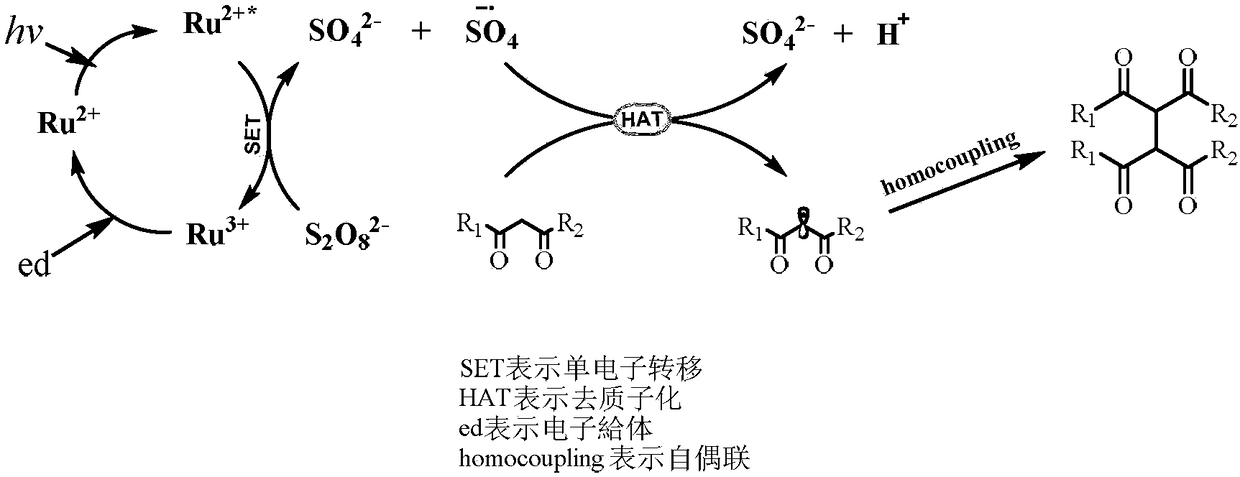

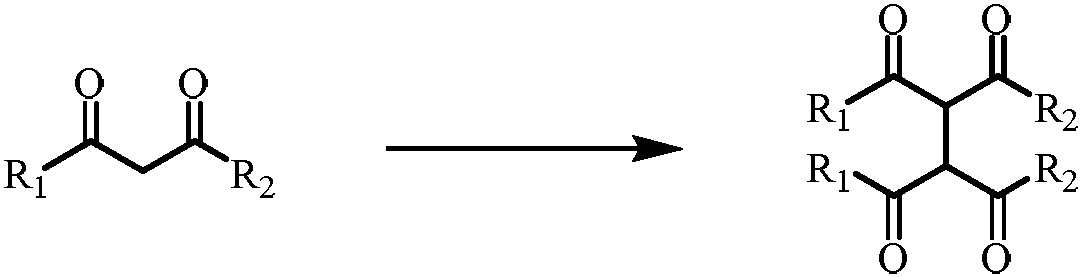

Method of dehydrogenation self-coupling of 1,3-dicarbonyl compound with visible light catalysis

A compound, dicarbonyl technology, applied in the field of organic catalysis, can solve problems such as easy occurrence of by-products, tedious preparation work, large yield loss, etc., and achieve the effects of reducing solvent polarity, improving energy utilization rate, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

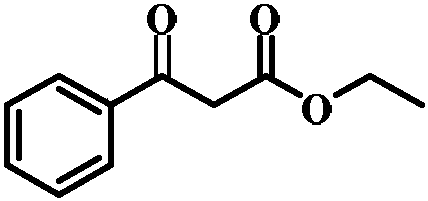

Embodiment 1

[0039] Weigh terpyridyl ruthenium(II) chloride hexahydrate (0.006mmol, 2% equiv) and potassium persulfate (0.45mmol, 1.5equiv) into the reactor, add ethyl benzoyl acetate (0.3mmol, 1equiv) , 1,4-dioxane (0.15mmol, 0.5equiv), mixed with solvent acetonitrile / water (V / V=1mL / 1mL). Put the reaction bottle into an oil bath at 25°C, and react for 24 hours under the irradiation of a 26W LED lamp. After the reaction, separation and purification were carried out to obtain product 1 (the reaction yield was 88%).

Embodiment 2

[0041] Weigh terpyridyl ruthenium (II) chloride hexahydrate (0.006mmol, 2% equiv) and potassium persulfate (0.45mmol, 1.5equiv) into the reactor, add ethyl p-fluorobenzoyl acetate (0.3mmol, 1equiv), 1,4-dioxane (0.15mmol, 0.5equiv), mixed into the solvent acetonitrile / water (V / V=1mL / 1mL). Put the reaction bottle into an oil bath at 25°C, and react for 24 hours under the irradiation of a 26W LED lamp. After the reaction, separation and purification were carried out to obtain the product 2 (the reaction yield was 82%).

Embodiment 3

[0043] Weigh terpyridyl ruthenium (II) chloride hexahydrate (0.006mmol, 2% equiv) and potassium persulfate (0.45mmol, 1.5equiv) into the reactor, add ethyl p-chlorobenzoyl acetate (0.3mmol, 1equiv), 1,4-dioxane (0.15mmol, 0.5equiv), mixed into the solvent acetonitrile / water (V / V=1mL / 1mL). Put the reaction bottle into an oil bath at 25°C, and react for 24 hours under the irradiation of a 26W LED lamp. After the reaction, separation and purification were carried out to obtain the product 3 (the reaction yield was 78%).

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com