Preparation method of micro-nano die profiled groove

A mold and micro-nano technology, which is applied in the field of micro-nano mold groove preparation, can solve the problems of not meeting the performance requirements, jagged edges, large roughness, etc., and achieve strong wear resistance, small thermal expansion coefficient, and thermal conductivity. The effect of high coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] A method for preparing a micro-nano mold groove, comprising the following steps:

[0031] Step 1. Coating: In a plasma-enhanced chemical vapor deposition coating machine, a Si sheet is used as a base material, and a SiC film is deposited on the surface of the base material;

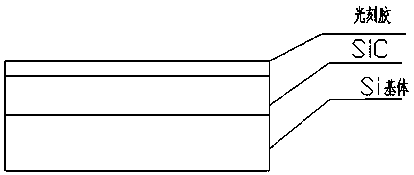

[0032] Step 2, photolithography: transfer the pattern of the mask to the SiC film layer by photolithography;

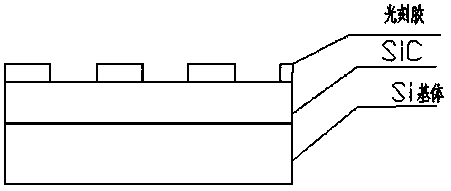

[0033] Step 3, etching: using an inductively coupled plasma etching machine to etch grooves on the SiC film layer.

[0034] The photolithography process of the present invention adopts a photoresist mask; the etching process adopts an ICP plasma etching process.

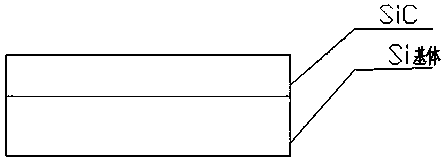

[0035] The present invention is realized in the following ways: Figure 1 to Figure 4 The steps of the fabrication process are illustrated.

[0036] Step 1, PECVD coating:

[0037] Such as figure 1 As shown, on the PECVD chemical vapor deposition coating machine, the SiC film layer is deposited on the surface of the Si subst...

Embodiment 1

[0053] A method for preparing a micro-nano mold groove, comprising the following steps:

[0054] (1) Coating: Deposit SiC thin film on the surface of Si base material on PECVD chemical vapor deposition coating machine;

[0055] (2) Photolithography: transfer the pattern of the mask to the SiC film layer by photolithography;

[0056] (3) Etching: use an etching machine to etch grooves on the SiC film layer.

[0057] In step (1), a 5 μm SiC thin film is deposited by PECVD chemical vapor phase method. SiH 4 、CH 4 The gas flow ratio is 6:1, the power setting is 300w, and the air pressure is 1Pa.

[0058] In step (3), an ICP etching machine is used to etch grooves on the SiC film layer. Etching gas using CF 4 , SF 6 , O 2 For etching gas, the flow rate ratio is 7:1:1, and the total flow rate is 40 sccm. The power of the upper / lower electrodes is set to 550 / 300W, and the air pressure is set to 1Pa.

[0059] The etched groove is "凵" type.

Embodiment 2

[0061] A method for preparing a micro-nano mold groove, comprising the following steps:

[0062] (1) Coating: Deposit SiC thin film on the surface of Si base material on PECVD chemical vapor deposition coating machine;

[0063] (2) Photolithography: transfer the pattern of the mask to the SiC film layer by photolithography;

[0064] (3) Etching: use an etching machine to etch grooves on the SiC film layer.

[0065] In step (1), a SiC film of 8 μm was deposited by PECVD chemical vapor phase method. SiH 4 、CH 4 The gas flow ratio is 2:1, the power setting is 300w, and the air pressure is 1Pa.

[0066] In step (3), an ICP etching machine is used to etch grooves on the SiC film layer. Etching gas using CF 4 , SF 6 , O 2 Etching gas, the flow rate ratio is 6:1:1, and the total flow rate is 30 sccm. The power of the upper / lower electrodes is set to 580 / 350W, and the air pressure is set to 3Pa.

[0067] The etched groove is "U" shape.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com