Preparation method of functionalized carbon quantum dot modified composite nanofiltration membrane

A technology of composite nanofiltration membrane and functionalized carbon, which is applied in the direction of chemical instruments and methods, membrane, membrane technology, etc., can solve problems such as the performance impact of composite nanofiltration membrane, achieve excellent anti-pollution performance, good industrial production basis, good Effect of Salt Retention Capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A preparation method of a composite nanofiltration membrane modified by functionalized carbon quantum dots:

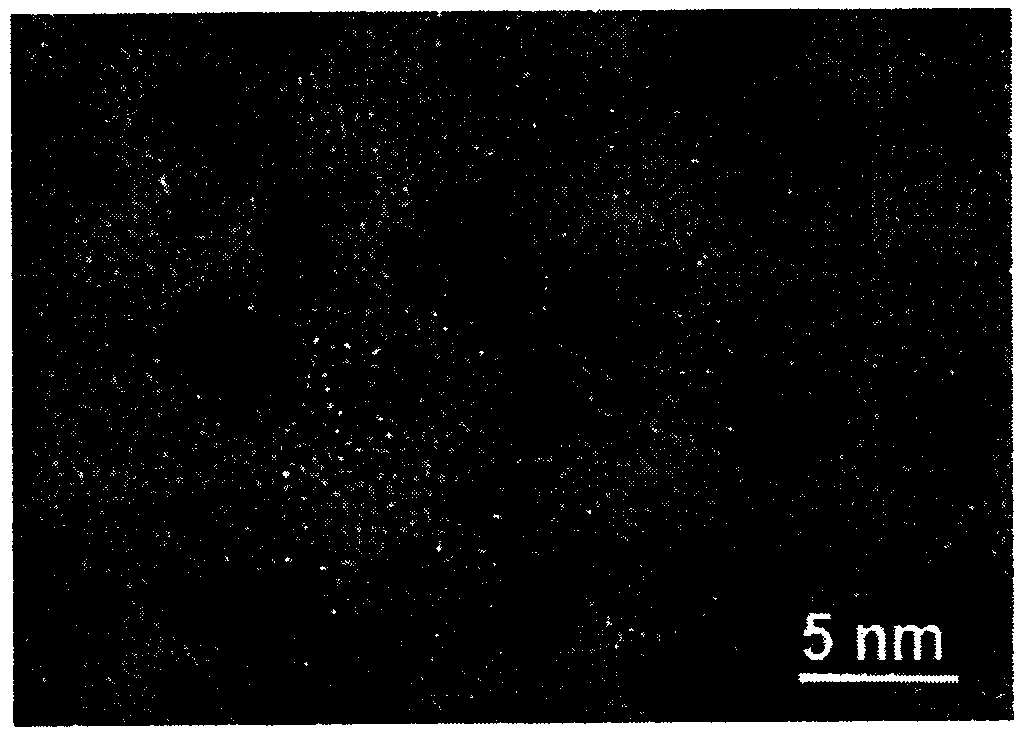

[0021] (1) Stir and dissolve citric acid and sodium polyethylene sulfonate (mass ratio is 2:1) in water, then remove the water to obtain a mixed powder of citric acid and polyethylene sulfonic acid; then, place the above mixed powder in Under a nitrogen atmosphere, pyrolyze at 200°C for 2 hours, wait for it to cool naturally, disperse the obtained brown product in water, purify by dialysis, and freeze-dry to obtain functionalized carbon quantum dots, such as figure 1 shown;

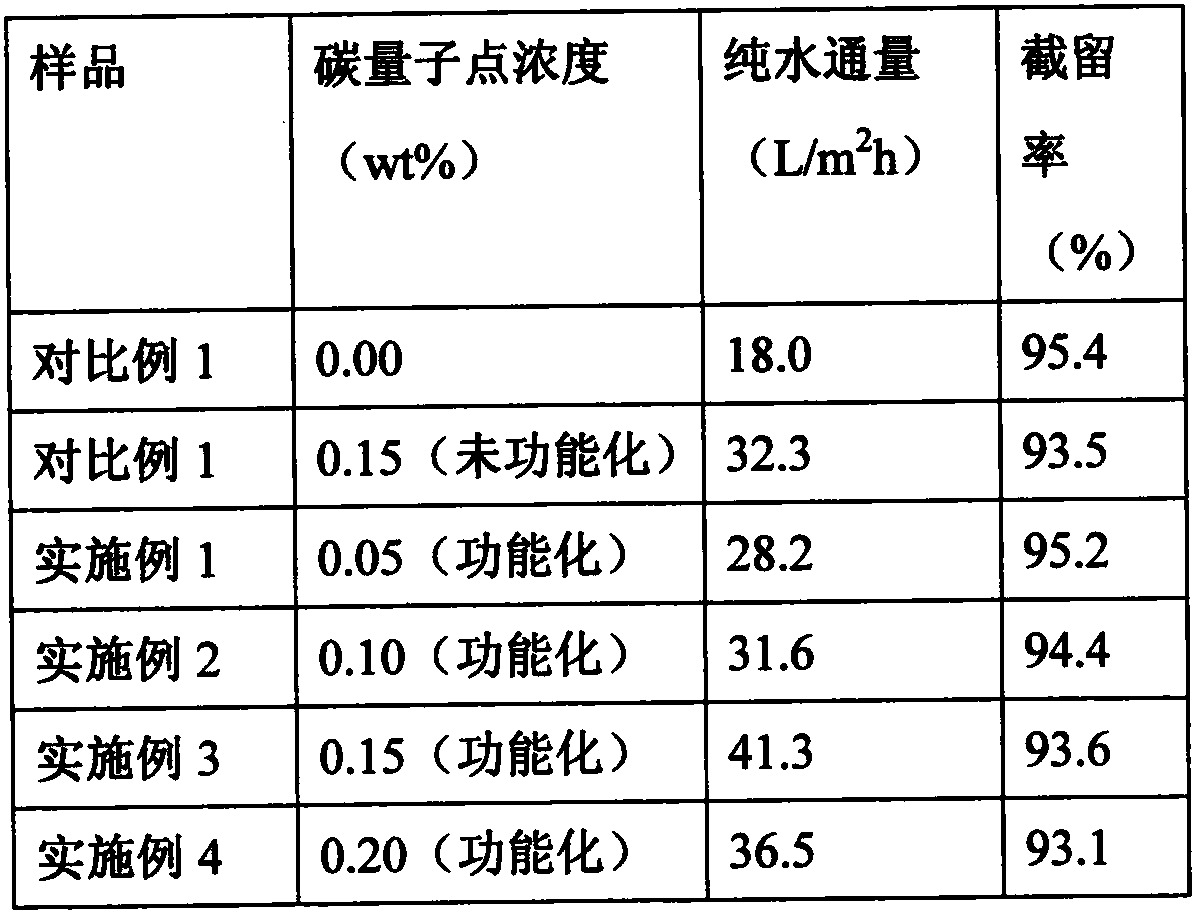

[0022] (2) Preparation of aqueous phase solution: Dissolve piperazine with a concentration of 1wt%, and 0.1wt% sodium hydroxide in deionized water, then add functionalized carbon quantum dots with a concentration of 0.05wt%, and ultrasonically disperse them evenly for 5 minutes ;Immerse the wet polysulfone support membrane into the aqueous phase solution for 10 minutes, take it out, roll t...

Embodiment 2

[0026] A preparation method of a composite nanofiltration membrane modified by functionalized carbon quantum dots:

[0027] (1) Stir and dissolve citric acid and sodium polyethylene sulfonate (mass ratio is 2:1) in water, then remove the water to obtain a mixed powder of citric acid and polyethylene sulfonic acid; then, place the above mixed powder in Under nitrogen atmosphere, pyrolyze at 200°C for 2 hours, wait for it to cool naturally, disperse the obtained brown product in water, purify by dialysis, and freeze-dry to obtain functionalized carbon quantum dots;

[0028] (2) Preparation of aqueous phase solution: Dissolve piperazine with a concentration of 1wt%, and 0.1wt% sodium hydroxide in deionized water, then add functionalized carbon quantum dots with a concentration of 0.1wt%, and ultrasonically disperse them evenly for 5 minutes ;Immerse the wet polysulfone support membrane into the aqueous phase solution for 10 minutes, take it out, roll the surface of the support me...

Embodiment 3

[0032] A preparation method of a composite nanofiltration membrane modified by functionalized carbon quantum dots:

[0033] (1) Stir and dissolve citric acid and sodium polyethylene sulfonate (mass ratio: 2:1) in water, then remove the water to obtain a mixed powder of citric acid and polyethylene sulfonic acid; then, place the above mixed powder in Under nitrogen atmosphere, pyrolyze at 200°C for 2 hours, wait for it to cool naturally, disperse the obtained brown product in water, purify by dialysis, and freeze-dry to obtain functionalized carbon quantum dots;

[0034] (2) Preparation of aqueous phase solution: Dissolve piperazine with a concentration of 1wt%, and 0.1wt% sodium hydroxide in deionized water, then add functionalized carbon quantum dots with a concentration of 0.15wt%, and ultrasonically disperse them evenly for 5 minutes ;Immerse the wet polysulfone support membrane into the aqueous phase solution for 10 minutes, take it out, roll the surface of the support mem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com