Quick-charging type lithium-ion battery and preparation method thereof

A lithium-ion battery and electrolyte technology, which is applied in the manufacture of electrolyte batteries, battery electrodes, secondary batteries, etc., can solve the problems of low charging rate and poor cycle performance, and achieve improved rate charge and discharge performance, low equipment requirements, The effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0057] In one embodiment, the preparation method of the fast-charging lithium-ion battery at least includes the following steps:

[0058] Step S01. Make the positive electrode carbon layer material and the first solvent into the first slurry, and apply the first slurry on the surface of the positive electrode current collector, dry it, and prepare it for use; prepare the negative electrode carbon layer material with the second solvent Form the second slurry, and apply the second slurry on the surface of the negative electrode current collector, dry it, and set it aside;

[0059] Step S02. The material of the positive electrode material layer and the third solvent are made into a positive electrode slurry, and coated on the surface of the positive electrode current collector obtained in step S01, and dried, rolled, and cut to obtain a positive electrode sheet; the negative electrode material layer The material and the fourth solvent are used to make negative electrode slurry, a...

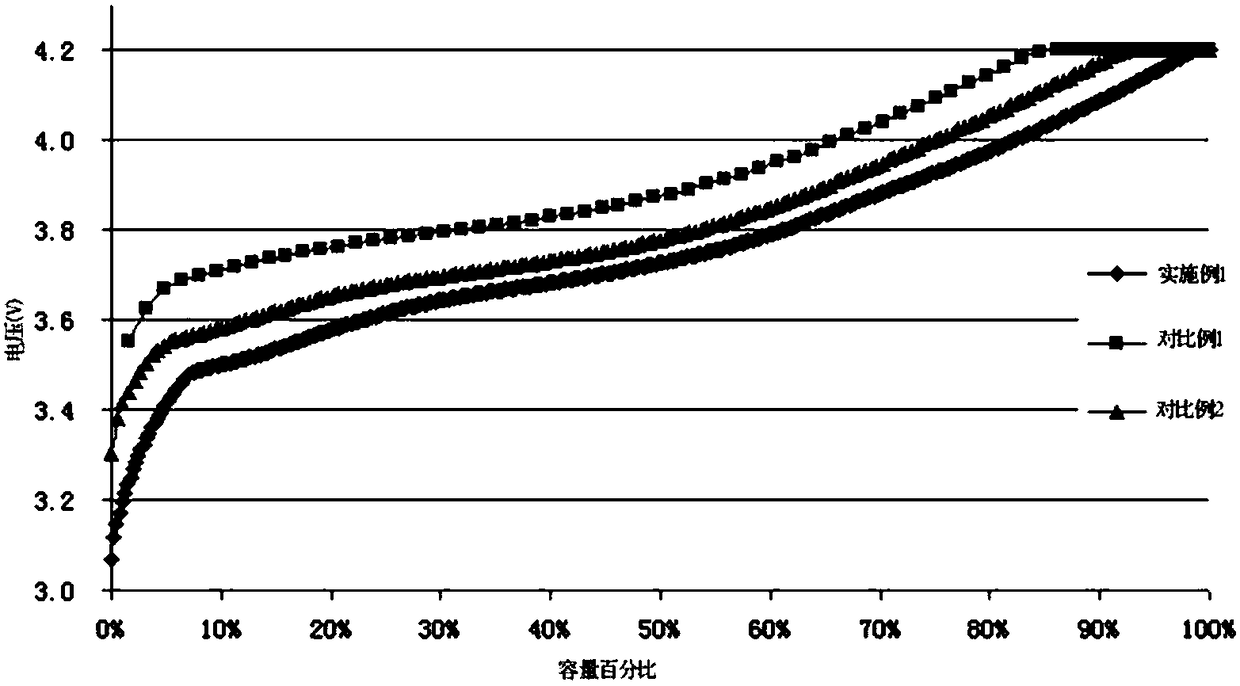

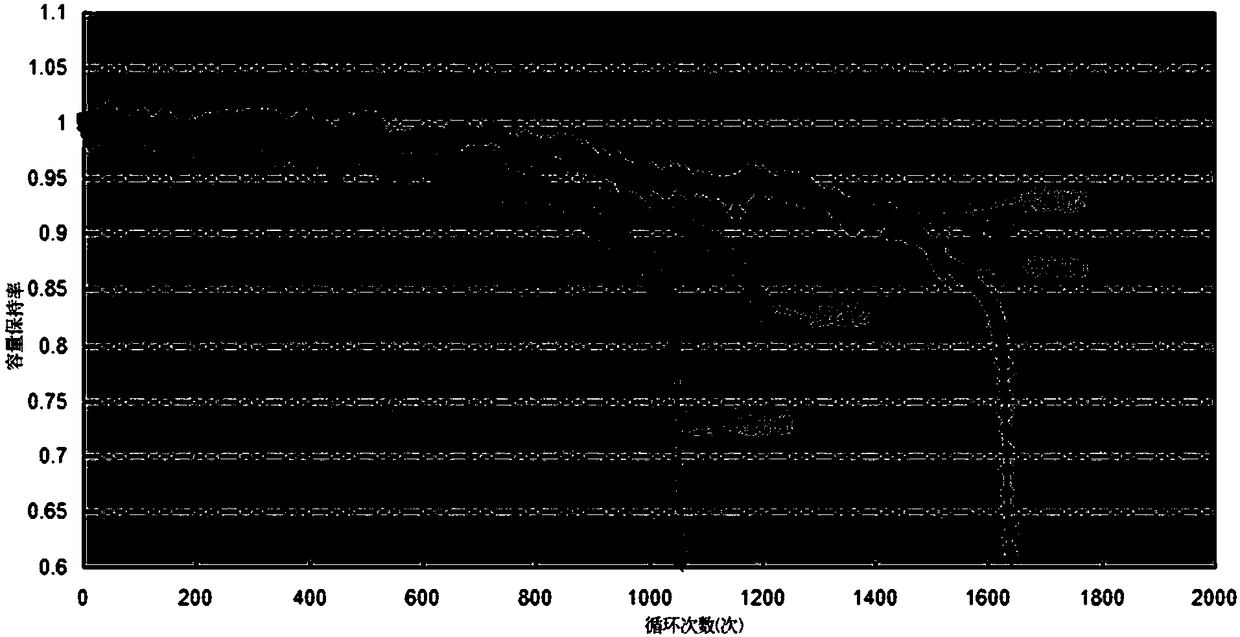

Embodiment 1

[0078] A fast charging type lithium ion battery and preparation method thereof, wherein, the parameters of the fast charging type lithium ion battery are as follows:

[0079] The positive active material is LiNi 0.5 co 0.2 mn 0.3 o 2 , D50 is 5μm, specific surface area ≥ 0.83m 2 / g, the surface coating accounted for 0.3% Al of the positive electrode active material mass percentage 2 o 3 , the positive electrode conductive agent is a mixture of conductive carbon black, carbon nanotubes, and graphene grown by chemical vapor deposition, wherein the number of layers of graphene is ≤ 5 layers, and, according to the mass ratio, it is conductive carbon black: carbon nanotubes : graphene=1:1:0.15. The positive current collector is aluminum foil, and the surface of the aluminum foil is coated with a layer of conductive carbon black layer, and the thickness of the conductive carbon black layer is 1.0 μm.

[0080] Negative electrode active material is artificial graphite, D50 is 8...

Embodiment 2

[0094] A fast charging type lithium ion battery and preparation method thereof, wherein, the parameters of the fast charging type lithium ion battery are as follows:

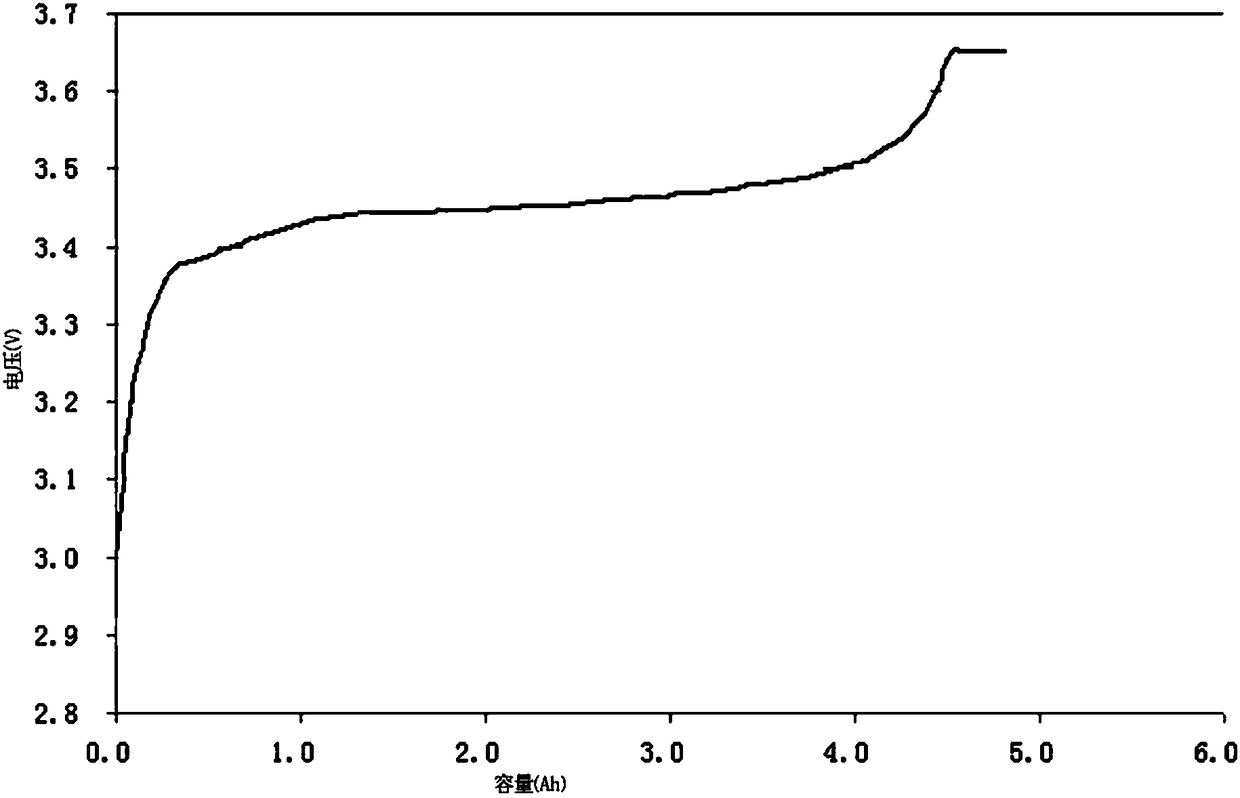

[0095] The positive electrode active material is lithium iron phosphate, D50 is 1μm, and the average specific surface area is ≥20.3m 2 / g, the surface is coated with a carbon layer that accounts for 1.5% of the mass percentage of the positive active material, and the positive conductive agent is a mixture of conductive carbon black, carbon nanotubes, and graphene grown by chemical vapor deposition, wherein graphene The number of layers is less than or equal to 5 layers, and the mass ratio is conductive carbon black: carbon nanotube: graphene = 1:1:0.3. The positive current collector is aluminum foil, and the surface of the aluminum foil is coated with a layer of conductive carbon black layer, the thickness of the conductive carbon black layer is 1.5 μm.

[0096] The negative electrode active material is a mixtu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| D50 | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com