A construction method for high ductility thermal insulation masonry wall

A technology of thermal insulation and construction method, applied in the direction of thermal insulation, walls, climate sustainability, etc., can solve problems such as energy consumption, achieve the effect of improving thermal insulation performance, improving thermal insulation performance, and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

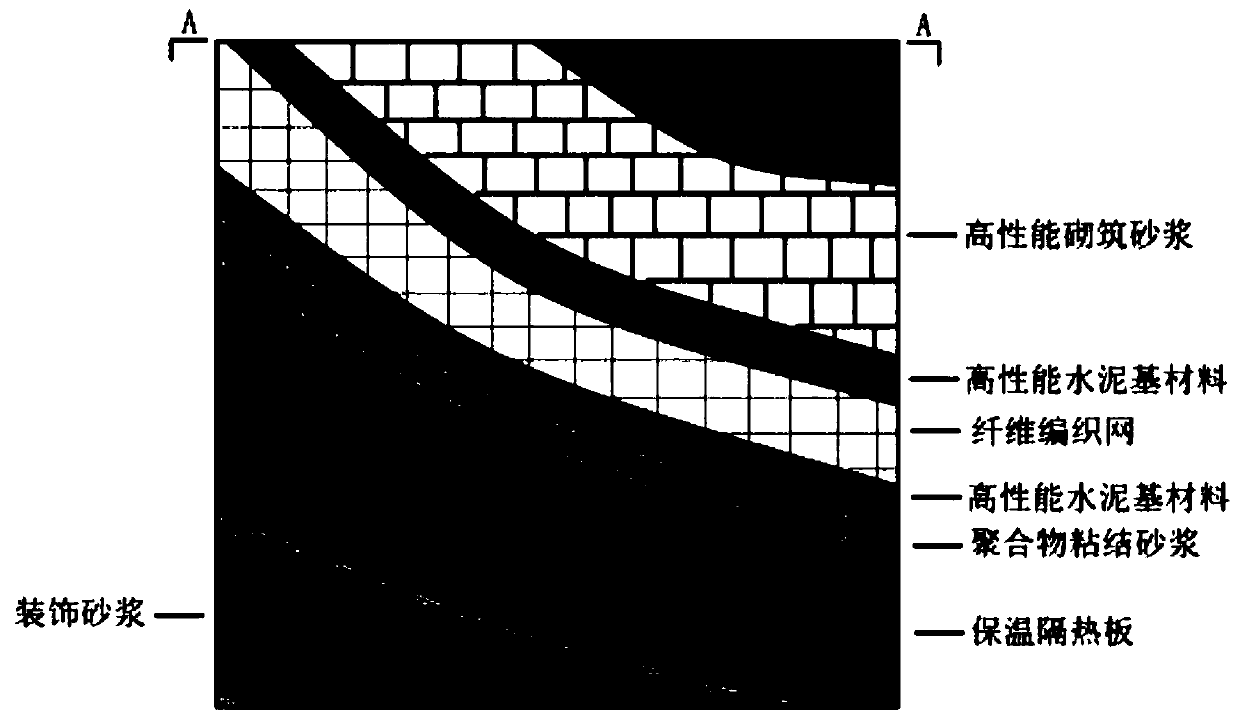

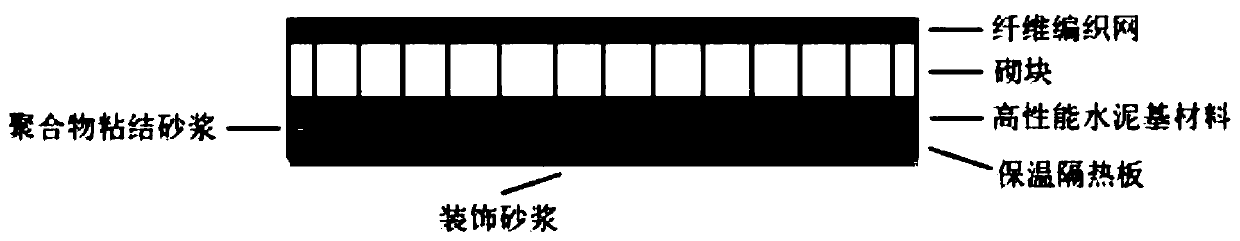

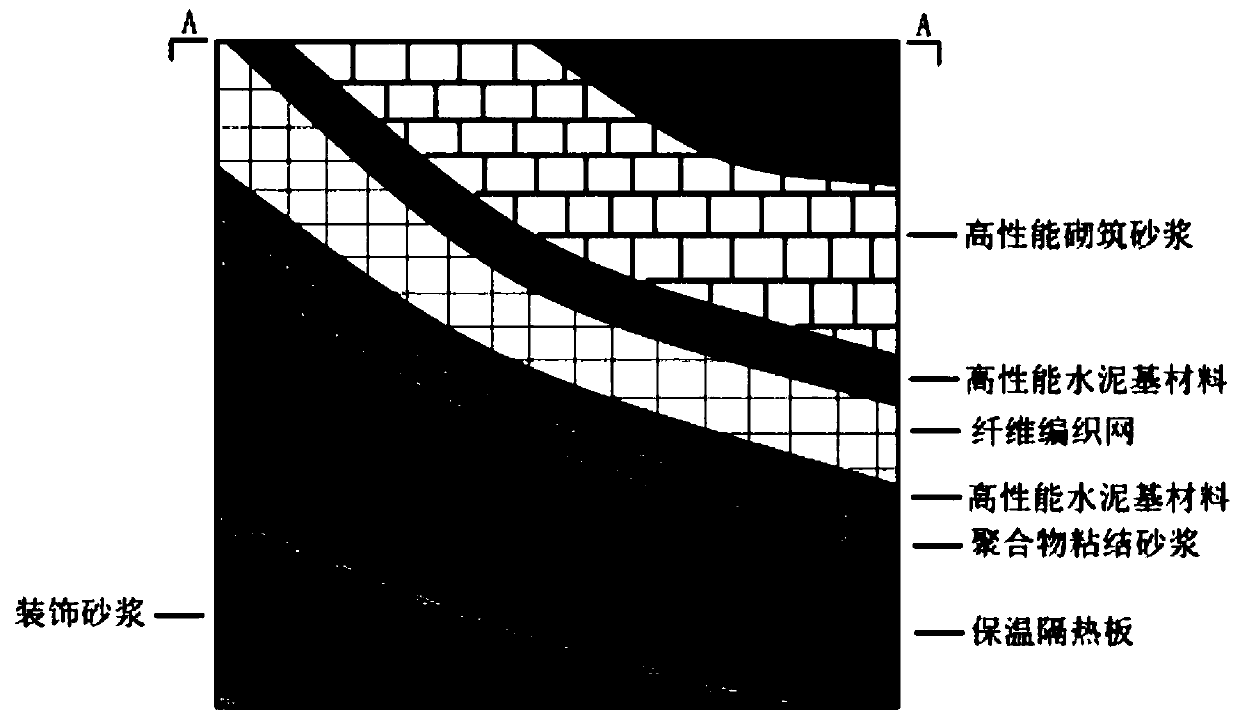

[0024] The present invention will be further described below in conjunction with the embodiment in the accompanying drawings:

[0025] The construction method of the high ductility thermal insulation masonry wall of the present invention, concrete steps are as follows:

[0026] 1) According to the design size of the cross-section of the masonry wall, apply a layer of high-performance masonry mortar with a thickness of 5 mm at the position where the masonry wall needs to be built; the position of the masonry wall should have basic flatness so that high Performance masonry mortar leveling; the high-performance masonry mortar includes: 42.5 ordinary Portland cement, Class I fly ash, silica sand, water and polycarboxylate superplasticizer, and its mass ratio is: 42.5 ordinary silicate Salt cement 500kg / m 3 , Class I fly ash 220kg / m 3 , 800kg / m of silica sand with a particle size of 0-0.6mm 3 , silica sand with a particle size of 0.6-1.2mm 400kg / m 3 , water 252kg / m 3 , polycar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com