Slip-resistant and noise-reducing foam porous concrete and preparation method thereof

A technology of porous foam and concrete, applied in the field of construction engineering materials, can solve the problems of low noise insulation rate, insufficient surface roughness, and reduced strength of foamed concrete, and achieve good permeability resistance, strong cation exchange adsorption capacity, and reduced surface tension effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

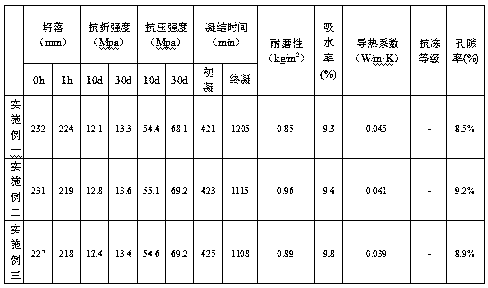

Embodiment 1

[0018] This embodiment provides a kind of anti-slip and noise-reducing foam porous concrete. The mass percentage of each raw material component in the concrete is: Portland cement 30%, fine sand 6%, crushed stone 20%, fly ash 10% %, vermiculite powder 10%, hydroxyapatite 2%, mullite 3%, linear alkylbenzene sulfonate sodium 2%, fatty alcohol sulfonate air-entraining agent 2%, sodium carbonate 2%, acetic acid 2%, water reducing agent 5%, water 6%.

[0019] In this embodiment, the fineness modulus of the fine sand is 1.5, the maximum particle size of the gravel cannot exceed 2.2 cm, and the water reducing agent is amino water reducing agent and polycarboxylate water reducing agent. The composite water reducer of the agent, the composite ratio of the amino water reducer and the polycarboxylate water reducer is: amino water reducer: polycarboxylate water reducer = 2:3, the bulk density of the fly ash 920kg / m 3 , the laser particle size parameter D50≤1.8μm, the water demand ratio ...

Embodiment 2

[0025] This embodiment provides a kind of anti-slip and noise-reducing foam porous concrete. The mass percentage of each raw material component in the concrete is: Portland cement 30%, fine sand 6%, crushed stone 20%, fly ash 19% %, vermiculite powder 8%, hydroxyapatite 1%, mullite 2%, linear alkylbenzene sulfonate sodium 1%, fatty alcohol sulfonate air-entraining agent 2%, sodium carbonate 1%, acetic acid 1%, water reducing agent 5%, water 6%.

[0026] In this embodiment, the fineness modulus of the fine sand is 1.8, the maximum particle size of the gravel cannot exceed 2.2 cm, and the water reducing agent is amino water reducing agent and polycarboxylate water reducing agent. The composite water reducer of the agent, the composite ratio of the amino water reducer and the polycarboxylate water reducer is: amino water reducer: polycarboxylate water reducer = 2:3, the bulk density of the fly ash 930kg / m 3 , the laser particle size parameter D50≤1.8μm, the water demand ratio o...

Embodiment 3

[0032] This embodiment provides a kind of anti-slip and noise-reducing foam porous concrete. The mass percentage of each raw material component in the concrete is: Portland cement 30%, fine sand 8%, crushed stone 20%, fly ash 12% %, vermiculite powder 8%, hydroxyapatite 1%, mullite 2%, linear alkylbenzene sulfonate sodium 1%, fatty alcohol sulfonate air-entraining agent 2%, sodium carbonate 1%, acetic acid 2%, water reducing agent 5%, water 8%.

[0033] In this embodiment, the fineness modulus of the fine sand is 1.6, the maximum particle size of the gravel cannot exceed 2.2 cm, and the water reducing agent is amino water reducing agent and polycarboxylate water reducing agent. The composite water reducer of the agent, the composite ratio of the amino water reducer and the polycarboxylate water reducer is: amino water reducer: polycarboxylate water reducer = 2:3, the bulk density of the fly ash 925kg / m 3 , the laser particle size parameter D50≤1.8μm, the water demand ratio o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com