Starting method of senseless permanent magnet synchronous motor

A magnetic synchronization and sensing technology, applied in the direction of synchronous generator control, generator control, motor generator control, etc., can solve the problems such as the unreliable start of the fan, the high energy consumption during the start-up process, and the longer start-up time. Fast closed-loop vector control, reduced start-up time, cost and size reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

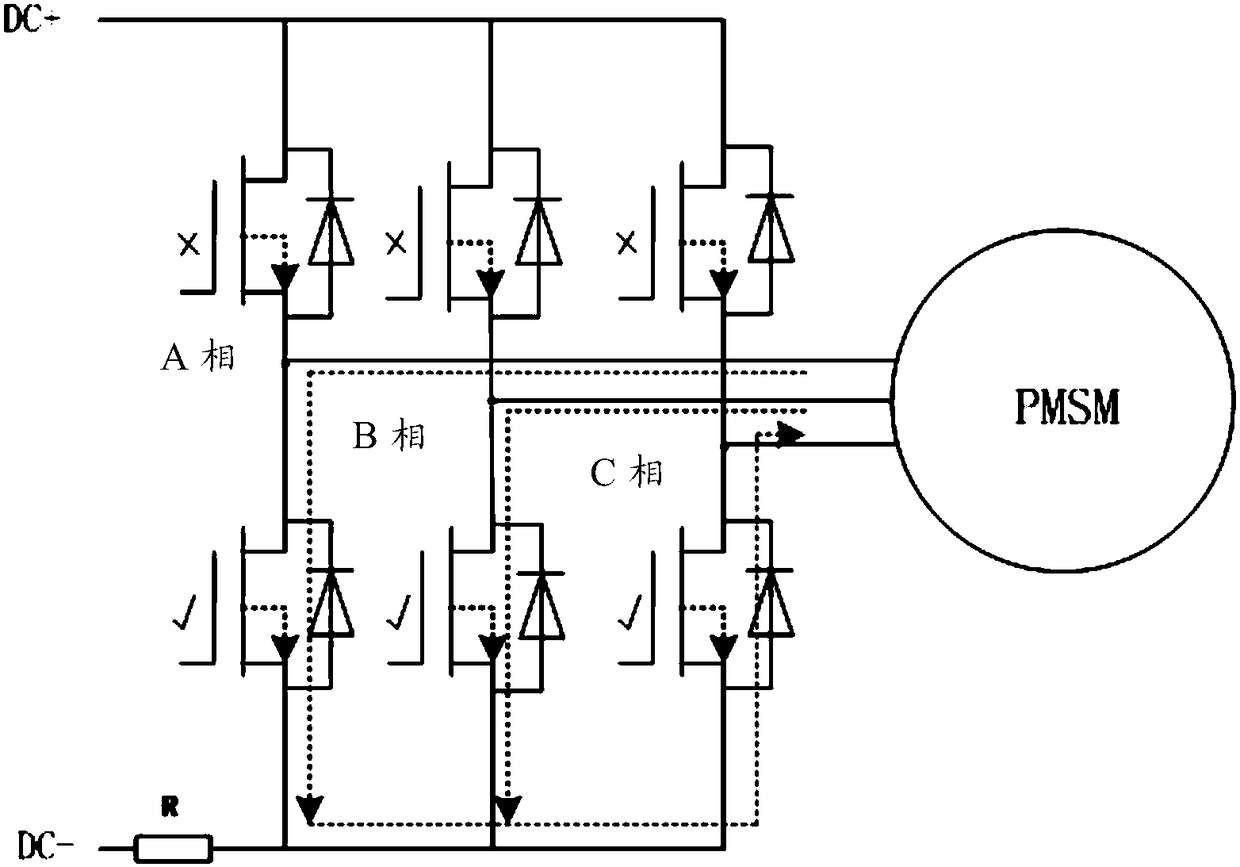

[0043] The embodiment of the present invention discloses a method for starting a sensorless permanent magnet synchronous motor. The sensorless permanent magnet synchronous motor is connected to a drive controller. The starting method includes the following steps: S10). The sampling module of the drive controller detects the induced current of the motor, and judges the rotation state of the motor based on the induced current of the motor; S20), determine whether the induced current of the motor is less than the predetermined value of the induced current, if yes, go to step S30), if not, go to step S40); S30), open-loop start control, switch to closed-loop vector control after the motor rotor is pulled into synchronization and reach the predetermined target speed; S40), determine whether the motor is in the forward or reverse state, if it is in the forward state, enter the step to enter Step S50), if not, go to step S60); S50), forward rotation closed-loop vector start control; S6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com