Rare earth phthalocyanine sandwich layered structured negative electrode material and preparation method thereof

A technology of negative electrode material and sandwich layer, applied in the field of rare earth phthalocyanine sandwich layer structure compound, can solve problems such as battery performance degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

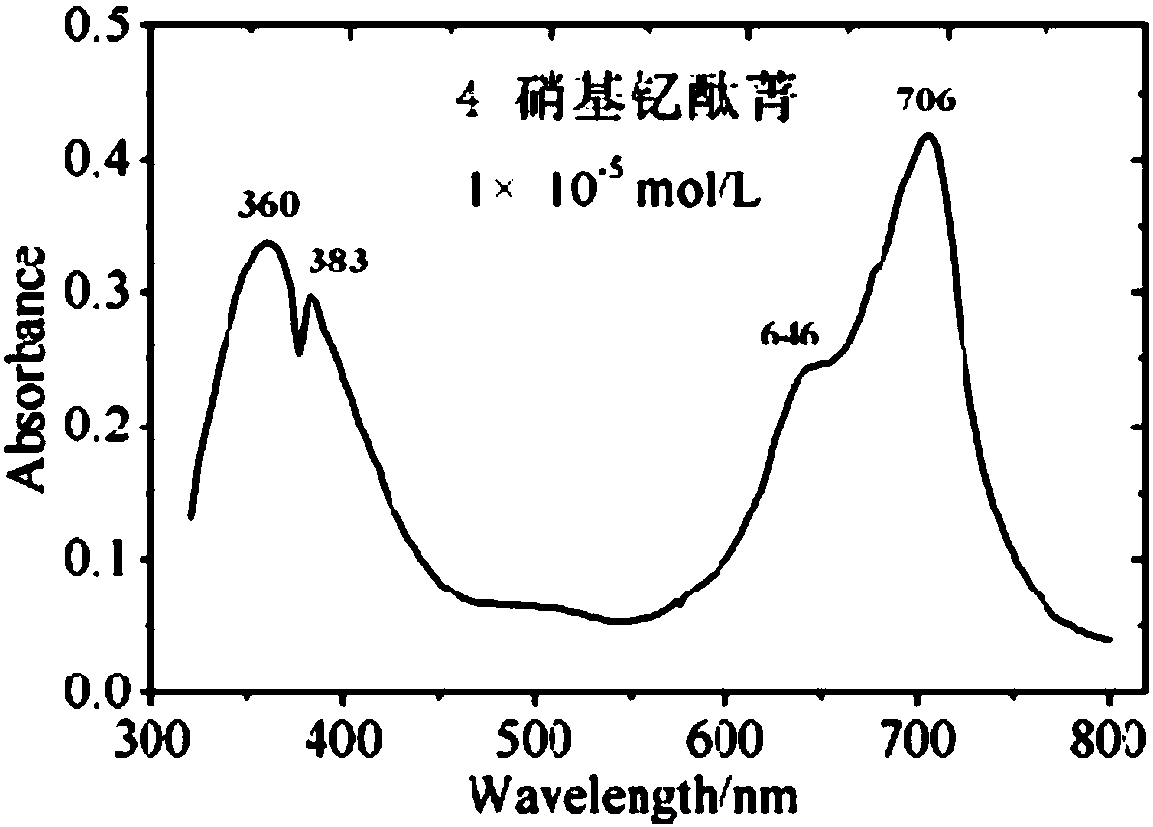

[0121] Synthesis Example 1: Solid phase synthesis of 4-nitroyttrium phthalocyanine

[0122] (1) Weigh 4-nitrophthalic anhydride (0.1mol), anhydrous YCl 3 (0.0125mol), ammonium molybdate (0.002mol) and urea (4mol), grind them into fine particles with a mortar, and then mix them together, and continue grinding until the powder particles of each component are mixed uniformly to obtain a mixed raw material , and finally transferred to a 500ml beaker;

[0123] (2) Cover the beaker containing the mixed raw materials with a glass cover, place it in an oven and heat it slowly to 150°C, and keep it warm for 30 minutes. At this time, there will be bubbles inside the beaker;

[0124] (3) After no bubbles are generated in the beaker, the temperature of the system is raised to 190° C., and the reaction is carried out at a constant temperature for 5 hours. After cooling, a blue-black solid product is obtained in the beaker;

[0125] (4) Scrape the black solid from the beaker, crush it wit...

Embodiment 2

[0135] Synthesis Example 2: Liquid phase synthesis of 4-nitroyttrium phthalocyanine

[0136] (1) The 4-nitrophthalonitrile that takes 0.1mol joins in the there-necked flask that fills 200ml n-amyl alcohol, feeds N 2 And keep stirring, raise the temperature to 60°C, and keep it warm for 3h;

[0137] (2) Weigh 0.0125mol anhydrous YCl 3 Quickly add it into the three-necked bottle, then draw 1,8-diazabicycloundec-7-ene (DBU) catalyst with a disposable dropper, and drop 5 drops into the three-necked bottle, continue to pass through the N 2 Stir for 30min;

[0138] (3) Slowly raise the temperature to 140°C, and reflux at this temperature for 36 hours, the mixed solution gradually turns into a blue solution;

[0139] (4) After the reaction solution is cooled, it is poured into ethanol and stirred for 30 min, left to settle, filtered, and dried to obtain a blue-black solid phthalocyanine compound.

[0140] (5) The black phthalocyanine solid powder obtained above was recrystallized...

Embodiment 3

[0143] Synthesis Example 3: Solid Phase Synthesis of 4-Nitroeuropium Phthalocyanine

[0144] (1) Weigh 4-nitrophthalic anhydride (0.1mol), anhydrous EuCl 3 (0.0167mol), ammonium molybdate (0.003mol) and urea (6mol), grind them into fine particles with a mortar, and then mix them together, and continue grinding until the powder particles of each component are mixed uniformly to obtain a mixed raw material , and finally transferred to a 500ml beaker;

[0145] (2) Cover the beaker containing the mixed raw materials with a glass cover, place it in an oven and heat it slowly to 160°C, and keep it warm for 20 minutes. At this time, there will be bubbles inside the beaker;

[0146] (3) After no bubbles are generated in the beaker, the temperature of the system is raised to 200° C., and the reaction is carried out at a constant temperature for 8 hours. After cooling, a blue-black solid product is obtained in the beaker;

[0147] (4) The black solid was scraped out from the beaker, c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com