Preparation method of crystalline organic thin film transistor controlled through crystalline solvent

A thin-film transistor and solvent-regulated technology, which is applied in semiconductor/solid-state device manufacturing, electric solid-state devices, semiconductor devices, etc., can solve problems such as waste of energy, amorphous films, cumbersome processing operations, etc., to improve efficiency and film-forming performance Good, time and energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

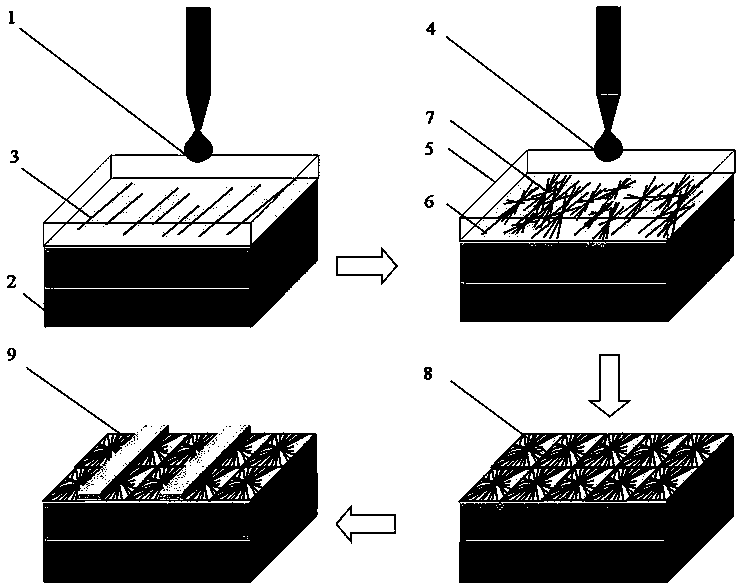

[0008] Si / SiO with a size of 1.5 cm × 1.5 cm 2 The base substrate (2) is first wiped with a cotton ball wetted with acetone solution, rinsed with acetone solution after wiping, then wiped with a cotton ball wetted with ethanol solution, rinsed with ethanol solution after wiping, and then rinsed with distilled water. Washed Si / SiO 2 Substrate The substrate (2) was blown dry with nitrogen gas, and dried in an oven at a temperature of 120°C. Treated Si / SiO 2 The base substrate (2) was taken out, and TCB was dissolved in chloroform solvent at a volume fraction of 1% to form a TCB solution (1) and added dropwise to Si / SiO 2 The substrate (2) is placed on the substrate until the solution covers the substrate. After 15 s, when TCB just started to form a small amount of crystals (3), 40 μL of rubrene solution (4) dissolved in chloroform solvent was added dropwise. With the volatilization of the chloroform solvent (5), the TCB first forms a uniform and directional substrate modific...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com