Rope-guiding hydraulic winch

A hydraulic winch and rope pulling technology, applied in the direction of hoisting device, spring mechanism, etc., can solve the problems of easy rope, many layers, etc., achieve orderly arrangement, improve the effect of rope arrangement, and avoid the effect of disordered arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

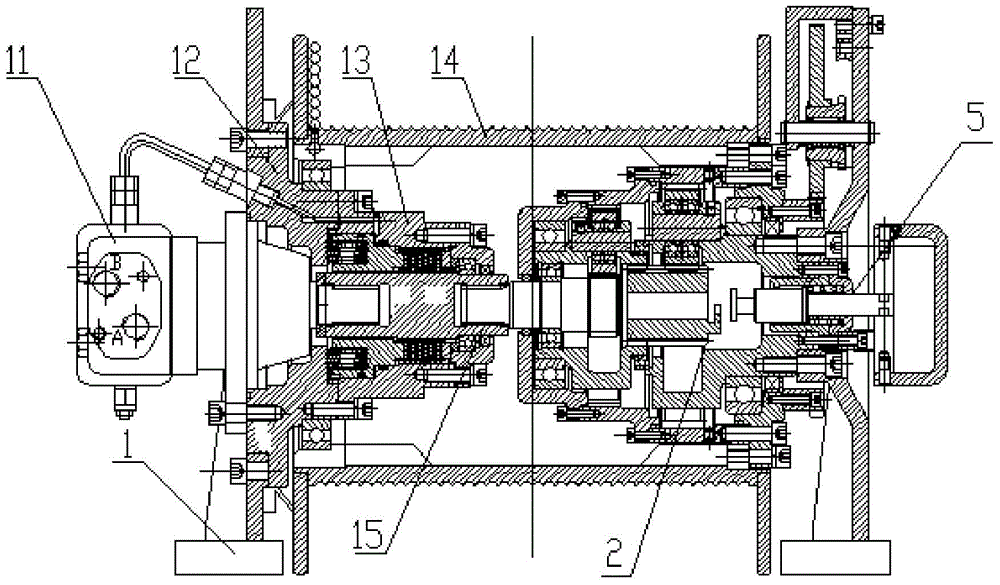

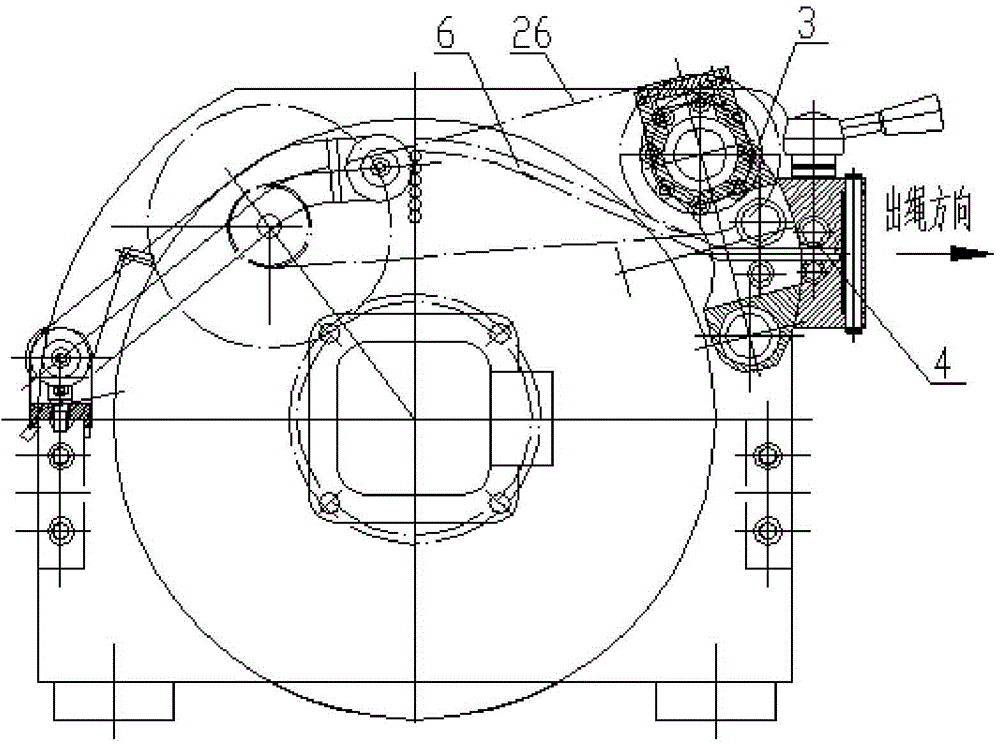

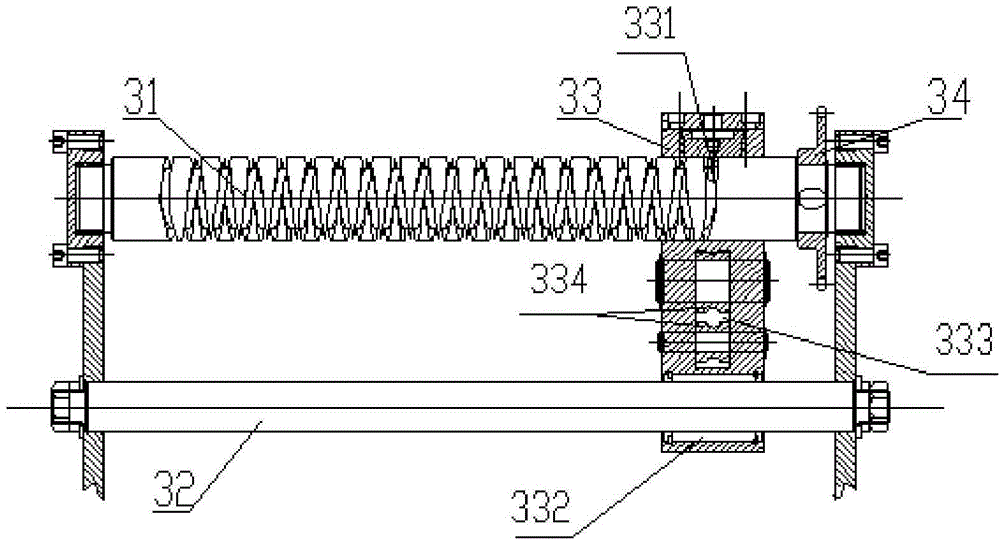

[0026] Such as Figure 1 to Figure 9 As shown, a rope hydraulic winch includes a bracket 1 and a drum 14 mounted on the bracket 1. A hydraulic motor 11 and a brake 13 are provided on the first side of the inner cavity of the drum 14 in the axial direction. A planetary gear reduction device 2 is provided on the second side of the axial direction. The output shaft of the hydraulic motor 11 is connected with the input shaft 211 of the planetary gear reduction device 2. The planetary gear reduction device 2 drives the drum 14 to rotate, and the rope hydraulic winch There is also an automatic rope arrangement 3. The hydraulic motor 11 is mounted on the motor connecting plate 12, and the motor connecting plate 12 is provided with an axial flange which extends into the inside of the drum 14 between the axial flange and the inner ring of the drum. A bearing is provided, and the output end of the hydraulic motor 11 is installed in the inner cavity of the motor connecting plate 12. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com