Treatment system and method for acrylic acid and ester waste oil of acrylic acid

An acrylic acid and oil treatment technology, applied in combustion methods, separation methods, liquid fuel pretreatment, etc., can solve the problems of poor fluidity, low operating energy consumption, etc., and achieve low energy consumption, lower flow resistance and high combustion efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

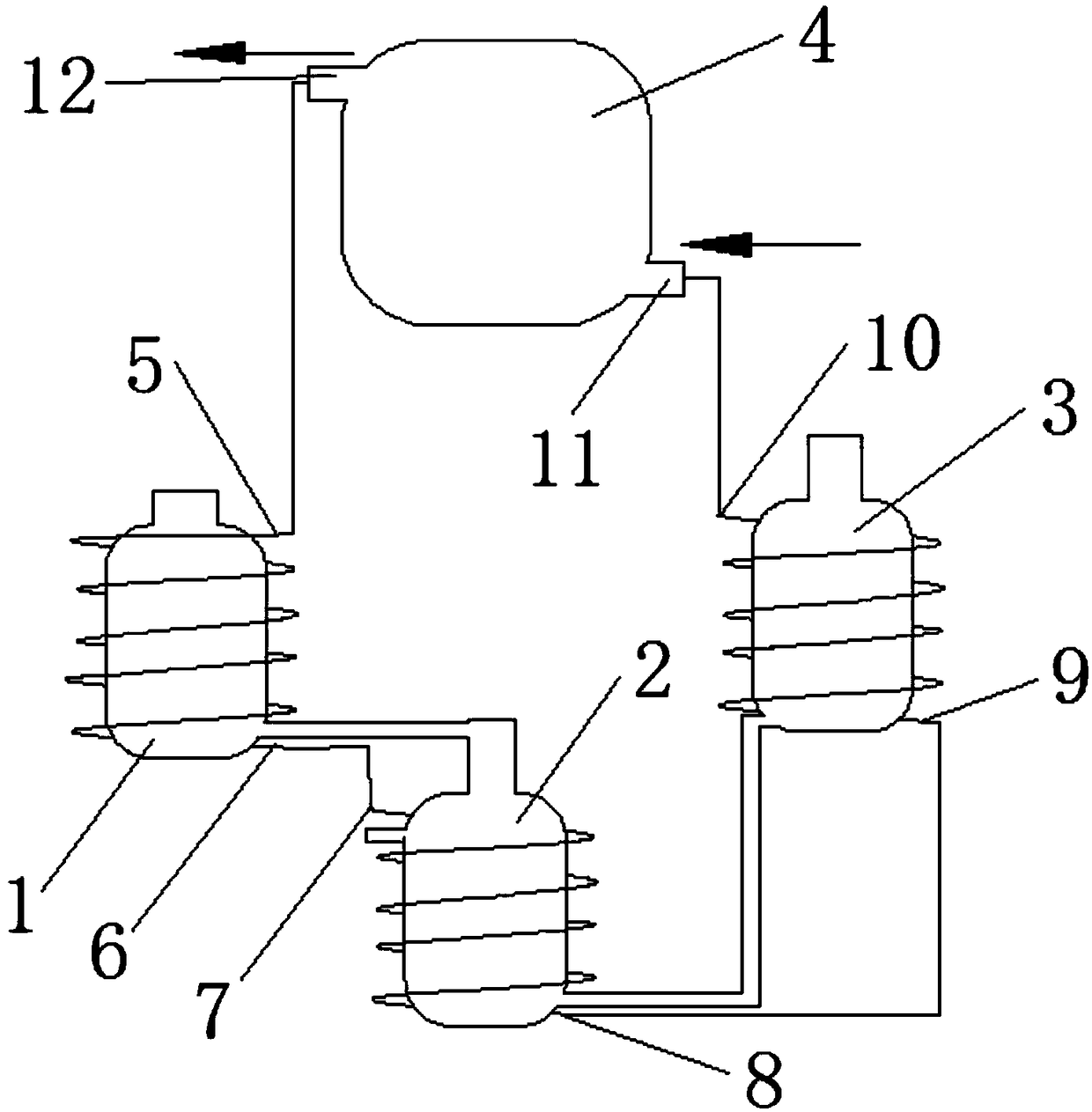

[0042] The process flow chart of this embodiment can be found in figure 1 , the present embodiment is to process 2000kg / h of acrylic acid and ester waste oil, the waste oil combustion calculation and atomization combustion process operating parameters are as shown in Table 2, the incineration process conditions are as shown in Table 3, and other process conditions are as shown in Table 4 Show.

[0043] Table 2 Waste oil atomization combustion process conditions

[0044]

[0045] Among them, the low calorific value of acetic acid waste liquid is ignored.

[0046] Table 3 Incineration process conditions

[0047] serial number

name

unit

value

1

combustion temperature

℃

1100.00

2

ambient temperature

℃

-20~30.00

3

Waste oil generates heat

kcal / h

14326252.47

4

Smoke volume of waste oil

N m 3 / h

34011

5

Flue gas volume of waste water

N m 3 / h

2416

6

Total amount ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com