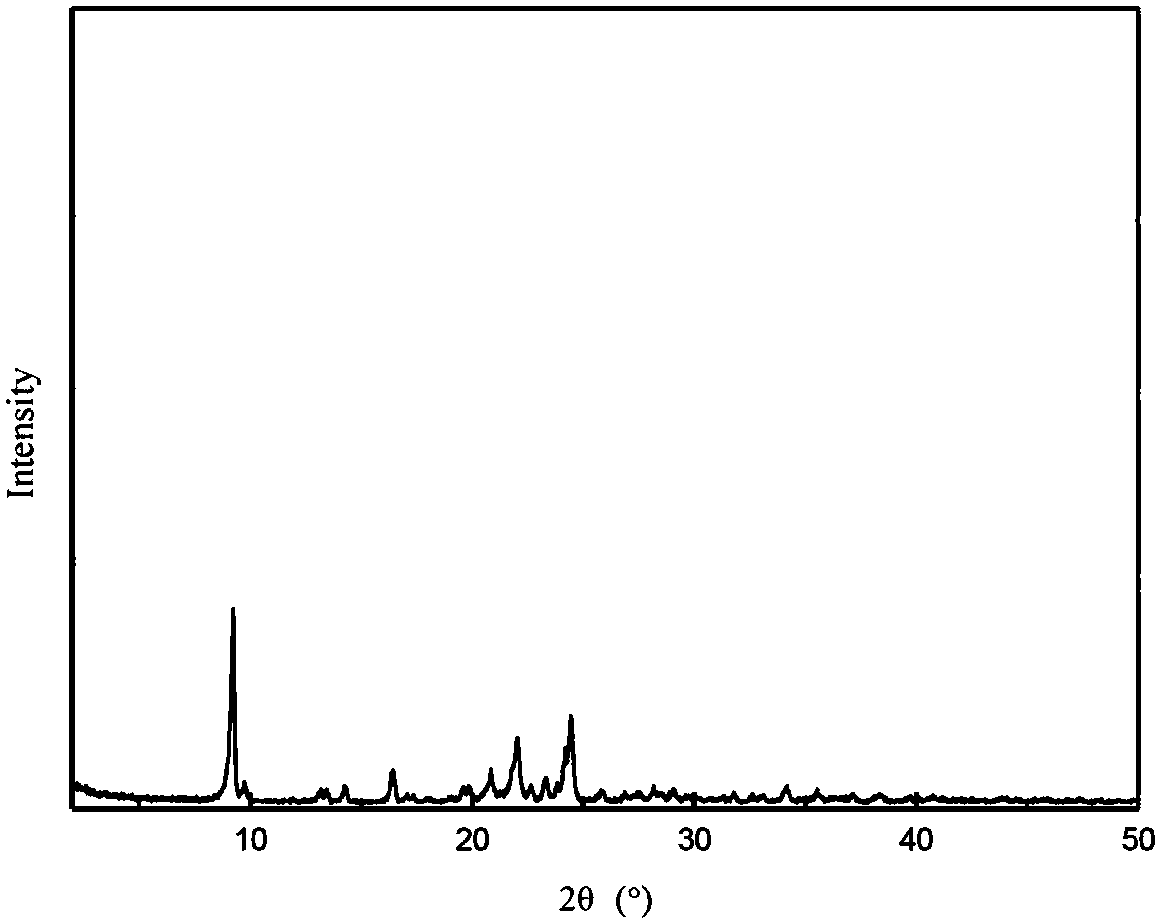

Preparation method of cefotaxime sodium spherical crystals

A technology of cefotaxime sodium and spherical crystals, which is applied in the field of preparation of cefotaxime sodium spherical crystals, can solve the problems of unfavorable industrialization, low bulk density, product burrs, etc., and achieve reduced industrialization costs, high bulk density, and uniform particle size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Step 1, at 10°C, prepare a mixed solution of water-isopropanol solvent, the mass ratio of water and isopropanol solvent is 1:1; add anhydrous sodium acetate and cefotaxime acid for salt-forming reaction, until The solution was clarified, and a mixed solution of cefotaxime sodium-water-isopropanol solvent with a concentration of cefotaxime sodium of 0.3 g / mL was prepared.

[0026] Step 2, keep the temperature at 10°C, add toluene, the ratio of the amount of toluene added to the volume of the solute (cefotaxime sodium) is 1:1, add cefotaxime sodium seed crystals, the amount of seed crystals added is based on the content of cefotaxime sodium 1% by mass, stirring for 5 minutes.

[0027] Step 3, keep the temperature at 10°C, add isopropanol solvent dropwise, the mass ratio of the dripping amount of isopropanol solvent to the content of isopropanol solvent in the mixed solvent is 0.5:1, and the rate of addition of isopropanol solvent is 0.1% / min, keep stirring until the crys...

Embodiment 2

[0031] Step 1, at 15°C, prepare a water-n-butanol mixed solution, the mass ratio of water and n-butanol is 1:2; add anhydrous sodium acetate and cefotaxime acid for salt-forming reaction until the solution is clear , to prepare the mixed solution of cefotaxime sodium-water-n-butanol whose concentration of cefotaxime sodium is 0.2g / mL.

[0032] Step 2, keep the temperature at 15°C, add dichloromethane, the ratio of the amount of dichloromethane added to the volume of the solute (cefotaxime sodium) is 1:2, add cefotaxime sodium seed crystals, the amount of seed crystals added is based on cefotaxime sodium The mass percent of oxime sodium content is 5%, and stirred for 15 minutes.

[0033] Step 3, keep temperature 15 ℃, drop n-butanol, the mass ratio of the amount of n-butanol added and the content of n-butanol in the mixed solvent is 1:1, and the rate of addition of n-butanol is 1% / min, Continue to stir until the crystals appear, and keep stirring for 1 hour after the dropwise ...

Embodiment 3

[0037] Step 1. Prepare a mixed solution of water-isobutanol at 25°C. The mass ratio of water and isobutanol is 1:3; add anhydrous sodium acetate and cefotaxime acid to perform a salt-forming reaction until the solution is clear , to prepare the mixed solution of cefotaxime sodium-water-isobutanol whose concentration of cefotaxime sodium is 0.25g / mL.

[0038] Step 2, keep the temperature at 25°C, add heptane, the ratio of heptane addition amount to solute (cefotaxime sodium) volume is 1:2, add cefotaxime sodium seed crystals, the seed crystal addition amount is based on cefotaxime sodium The mass percentage of the content is 10%, stirring for 30min.

[0039] Step 3, keep the temperature at 25°C, add isobutanol dropwise, the mass ratio of the amount of isobutanol added to the content of isobutanol in the mixed solvent is 1.5:1, and the rate of addition of isobutanol is 3% / min , keep stirring until the crystals appear, and keep stirring for 3 hours after the dropwise addition to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com