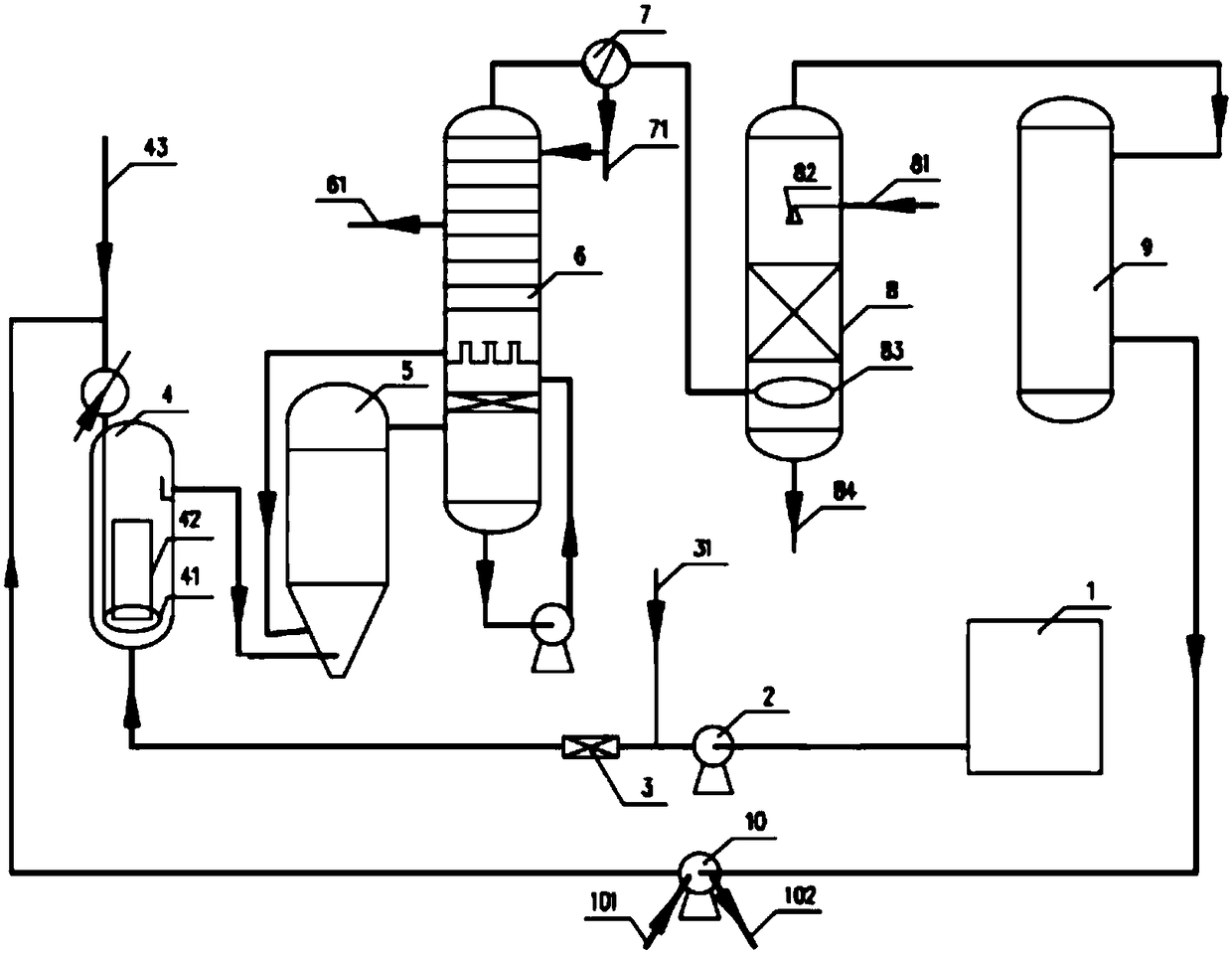

Adiponitrile production system

A production system and adiponitrile technology, applied in the chemical industry, can solve the problems of coke formation, poor mixing effect, side reactions, etc., and achieve the effect of prolonging the operation period, avoiding decomposition and coking, and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036]The molten adipic acid with a flow rate of 2400kg / h is sent from the adipic acid buffer tank 1, and the liquid phosphoric acid catalyst of 4.8kg / h is uniformly mixed through the mixer 3 at the outlet of the adipic acid feed pump, and then sent to the ammoniation reaction device 4. The reactor is fed with ammonia gas of 2236kg / h through the ammonia gas inlet 43 (the molar ratio of adipic acid is 8:1, that is, the excess of ammonia gas is 3 times), and the reaction is carried out under the conditions of 160°C and 90KPa, and the adipic acid The acid ammoniation rate is 95%. The ammoniated material enters the nitrilation reactor 5, and is heated to 260°C with VP-1 heat conduction oil steam with good thermal stability and low liquid phase viscosity to dehydrate to form adiponitrile, and cyclopentanone, ICCP will be produced at the same time. And other by-products and intermediate products such as cyanovaleric acid and cyanovaleramide. The adiponitrile containing the interme...

Embodiment 2

[0039] After flow is the molten adipic acid of 2400kg / h and the liquid phosphoric acid catalyst of 7.2kg / h by the circulation line of mixer and feed pump after uniform mixing, feed the ammonia gas of 2794kg / h (with the mol ratio of adipic acid 10:1, that is, the excess of ammonia is 4 times), wherein the fresh ammonia is about 485kg / h, and the circulating ammonia is about 2309kg / h. Under the conditions of 170° C. and 90 KPa, the ammoniation rate of adipic acid in the ammoniation reactor 4 is 96.5%. The ammoniated material enters the nitrilation reactor, and is dehydrated at 270°C by using VP-1 heat transfer oil steam to generate adiponitrile; the reaction will also generate cyclopentanone, ICCP and other by-products, cyanovaleric acid, cyano Intermediate products such as pentamide. The adiponitrile containing the intermediate product can also continue to enter the lower half of the separation tower for separation, and at the same time, a part of the circulating liquid is sent...

Embodiment 3

[0041] After flow is the molten adipic acid of 2400kg / h and the liquid ammonium phosphate catalyst of 16.2kg / h by the circulation line of mixer and feed pump after evenly mixing, pass into the ammonia gas of 4471kg / h (with the mole of adipic acid The ratio is 16:1, that is, the excess of ammonia is 7 times) to react, wherein the fresh ammonia is about 776kg / h, and the circulating ammonia is about 3695kg / h. Under the conditions of 180° C. and 90 KPa, the ammoniation rate of adipic acid in the ammoniation reactor 4 is 98.5%. The ammoniated material enters the nitrilation reactor, and is dehydrated at 290°C by using VP-1 heat transfer oil steam to generate adiponitrile; the reaction will also generate cyclopentanone, ICCP and other by-products, cyanovaleric acid, cyano Intermediate products such as pentamide. The adiponitrile containing the intermediate product can also continue to enter the lower part of the separation tower for separation, and the pipeline at the bottom of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com