One-way high-heat-conductivity Cf/Al composite material preparing method

A composite material, high thermal conductivity technology, applied in metal material coating process, ion implantation plating, coating and other directions, can solve the problems of low thermal conductivity, high thermal resistance, limited high thermal conductivity applications, etc., to improve thermal conductivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

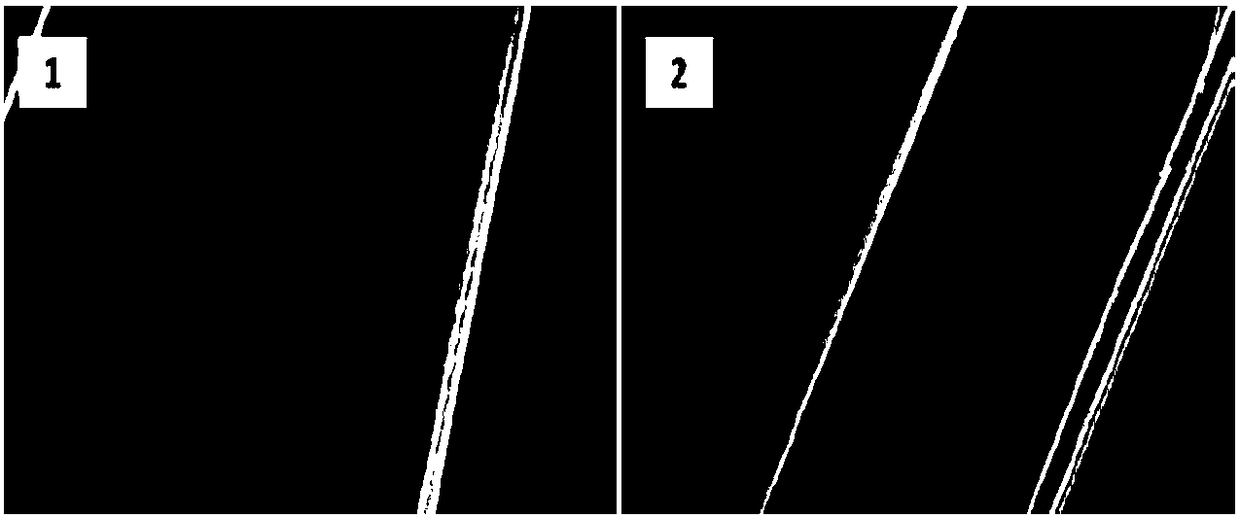

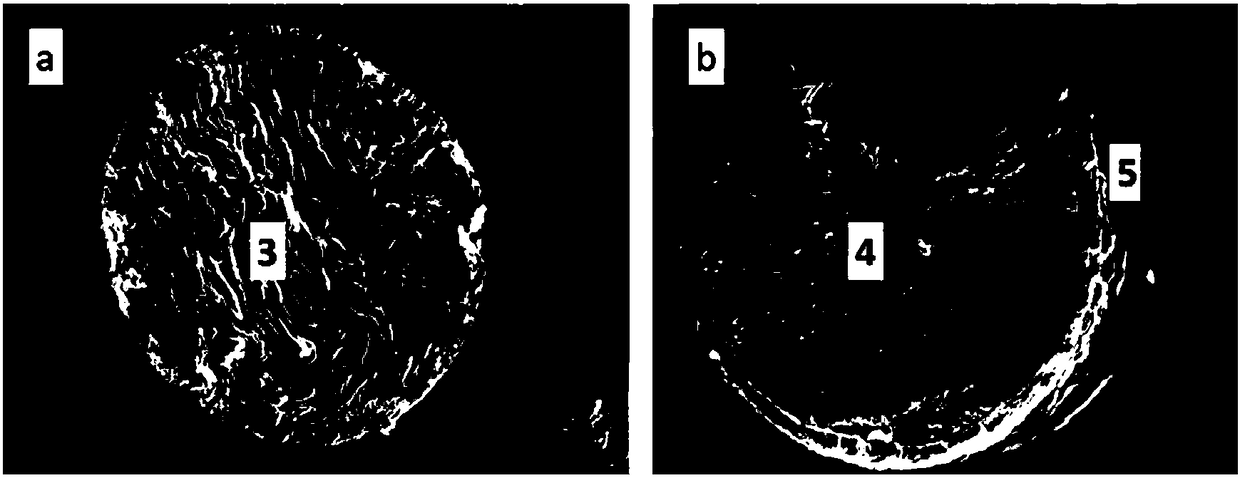

[0015] A unidirectional high thermal conductivity C f / Al composite material preparation method, using aluminum wire to roughen, figure 1 are the morphology of carbon fiber before and after roughening: 1 before roughening; 2 after roughening. The flattened high thermal conductivity mesophase pitch-based carbon fiber continuous filaments are fixed into a unidirectional fabric, and the high thermal conductivity mesophase pitch-based carbon fiber unidirectional fabric is coated with aluminum by physical vapor deposition. The evaporation rate of metal aluminum is 0.05 μm / min, and the single The rotation speed of the cloth is 2r / min, and the vacuum degree in the vacuum chamber is 5×10 -3 Pa, so that there is a layer of 0.1 μm-1 μm aluminum film on the surface of the carbon fiber, and the “carbon fiber unidirectional cloth pre-deposition material” is prepared. The above-mentioned "carbon fiber unidirectional cloth pre-deposition material" and aluminum powder are laminated and vacu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com