Zirconium phosphate matrix sub-conductor material and application thereof in fuel cell

A proton conductor, zirconium phosphate-based technology, used in fuel cells, circuits, electrical components, etc., can solve the problems of corrosion of materials and leaching of acid molecules, achieving low cost, mild reaction conditions, and avoiding the reduction of electrical power density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] H 3 PO 4 , ZrCl 4 , (NH 2 ) 2 CO and [BMMim]Cl were placed in a 10mL polytetrafluoroethylene reactor at a molar ratio of 2.04:0.64:2.5:1.33, sealed, heated to 180°C, heated for 12 hours, and then cooled to room temperature at 6°C / h, the product Washing alternately with a large amount of boiling water and ethanol until the impurities are completely removed, washing the obtained crystal product with ethanol, and drying at room temperature to obtain an inorganic ZrP material.

[0037] The structure of ZrP was determined by single crystal X-ray diffraction, and its structural information is summarized in Table 1.

[0038] Table 1 Structural information of ZrP

[0039]

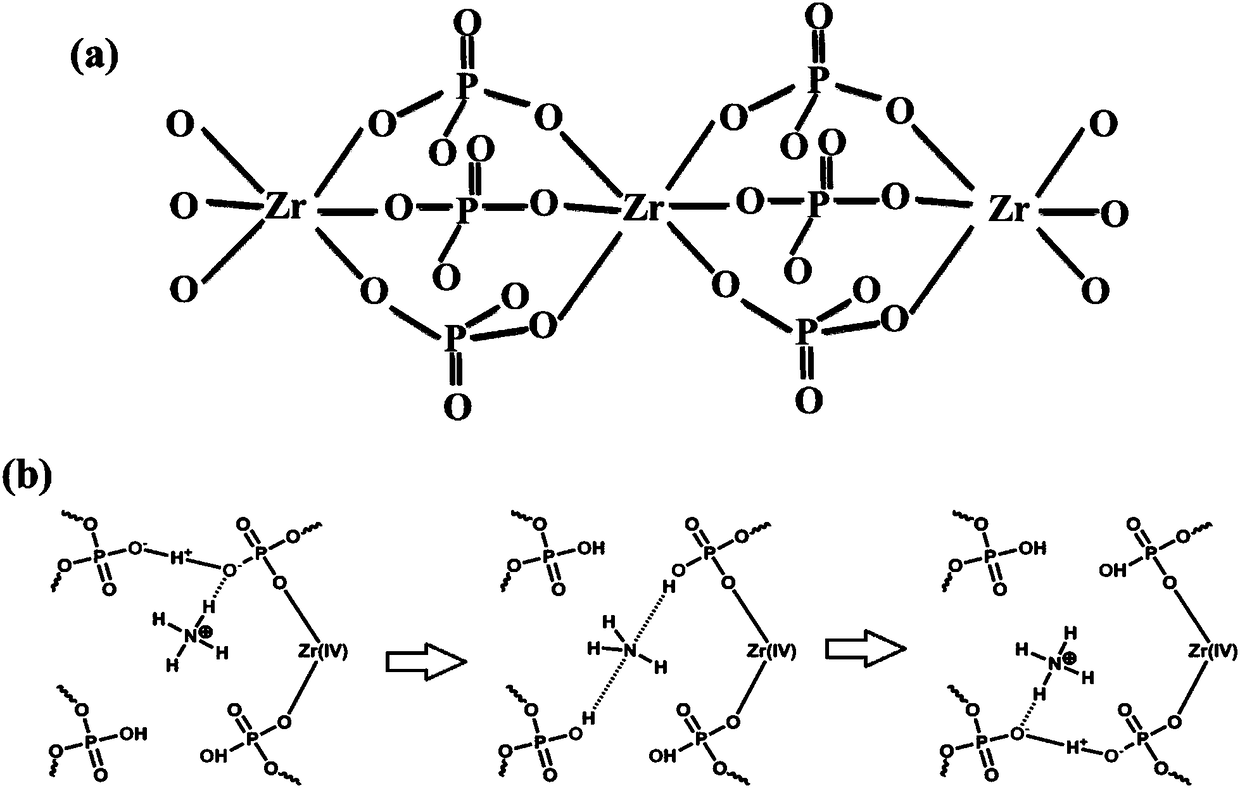

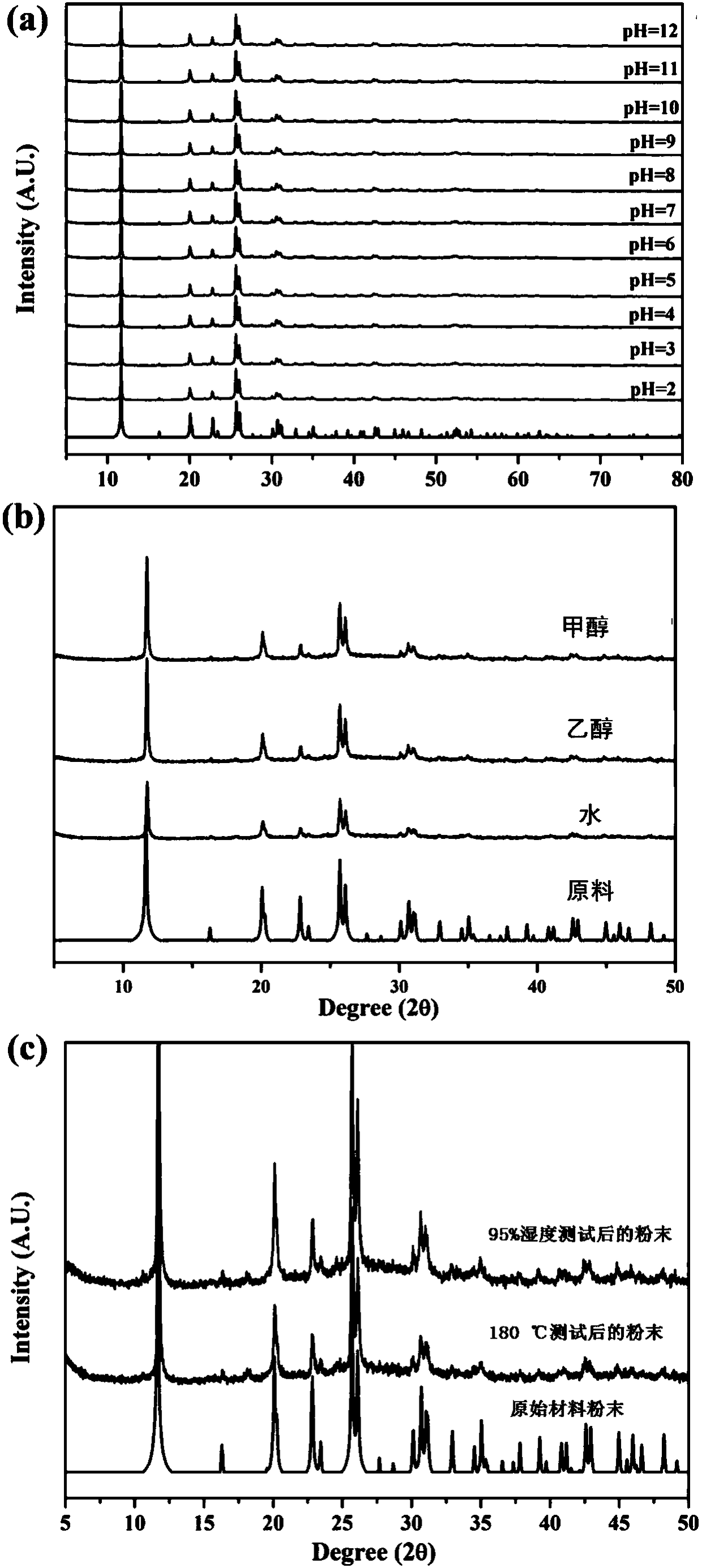

[0040] figure 1 a is a schematic diagram of the one-dimensional chain structure of the ZrP crystal structure, figure 1 b is a schematic diagram of the intrinsic proton hydrogen transfer along the c-axis inside the ZrP crystal structure. The ZrP structure of the present invention consists of a seri...

Embodiment 2

[0043] Preparation and Testing of Inorganic Zirconium Phosphate Crystalline Material (ZrP) Proton Conducting Sheet

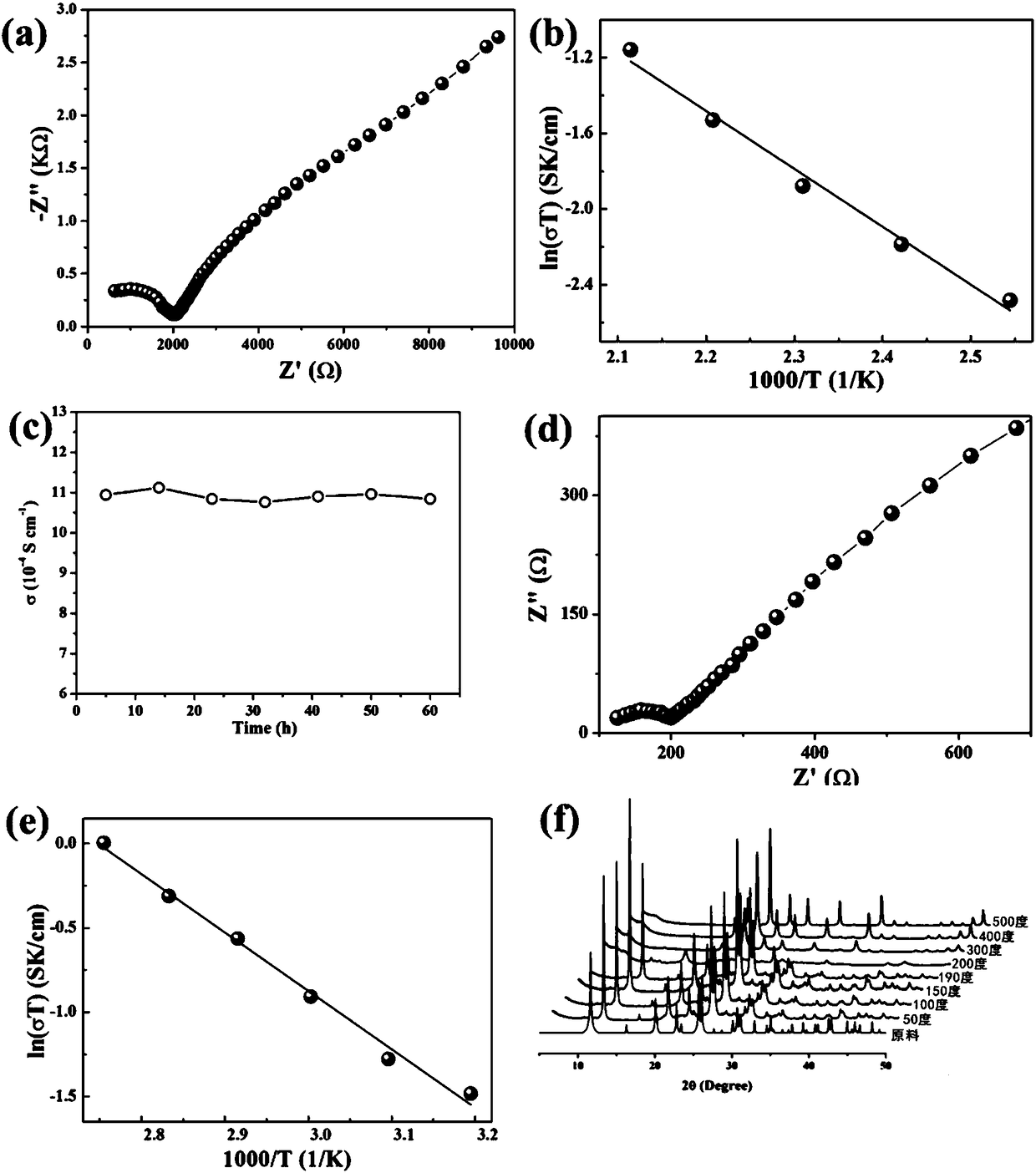

[0044] The ZrP crystal prepared in Example 1 was ground into a powder form with an agate mortar, and the powder was pressed into a proton conductive sheet with a diameter of 3 mm and a thickness ranging from 1 to 2 mm with a tablet press under a pressure of 1000 kg. The pressed proton conductive sheet was connected with a Solartron SI 1260 impedance / gain-phase analyzer with silver paste and gold wires for AC impedance measurement, with an AC voltage amplitude of 500mV and a frequency range of 5MHz to 1Hz. Under the test condition below 100°C, place the sample to be tested in a constant temperature-humidity box for AC impedance spectroscopy test; under the test condition above 100°C, place the sample to be tested in a tube furnace carry out testing. Proton conductivity was calculated by the following formula:

[0045] σ=L / RS

[0046] where S and L are the cros...

Embodiment 3

[0052] Preparation and Testing of Inorganic Zirconium Phosphate Crystalline Material (ZrP) Proton Exchange Membrane Fuel Cell (PEMFC)

[0053] Inorganic zirconium phosphate (ZrP) proton conduction membrane was prepared by hot pressing process. The ZrP crystalline material powder synthesized in Example 1 was physically mixed with 10 wt% polyvinylidene fluoride (PVDF) binder, and the PVDF was used to increase the density and strength of the zirconium phosphate battery sheet. The mixture was then hot-pressed at 180 °C for 0.5 h at 300 MPa. The obtained zirconium phosphate proton conducting membrane had a diameter of about 19 mm and a thickness of about 0.3 mm. A Pt / C anode, a zirconium phosphate proton-conducting membrane, and a Pt / C cathode constituted a single cell for electrochemical evaluation. Pt loading is 1.0mg / cm 2 Pt / C catalysts are used for the anode and cathode. Catalyst inks were prepared by mixing Pt / C powder with PTFE solution (3.1 wt% N,N-dimethylformamide) und...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com