High-frequency steam vacuum drying box and achieving method thereof

A vacuum drying oven and steam technology, which is applied in the direction of wood drying, drying solid materials, drying gas arrangement, etc., can solve the problems of slow water discharge speed, pressure difference, and affecting drying effect, so as to facilitate cleaning and improve product quality rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

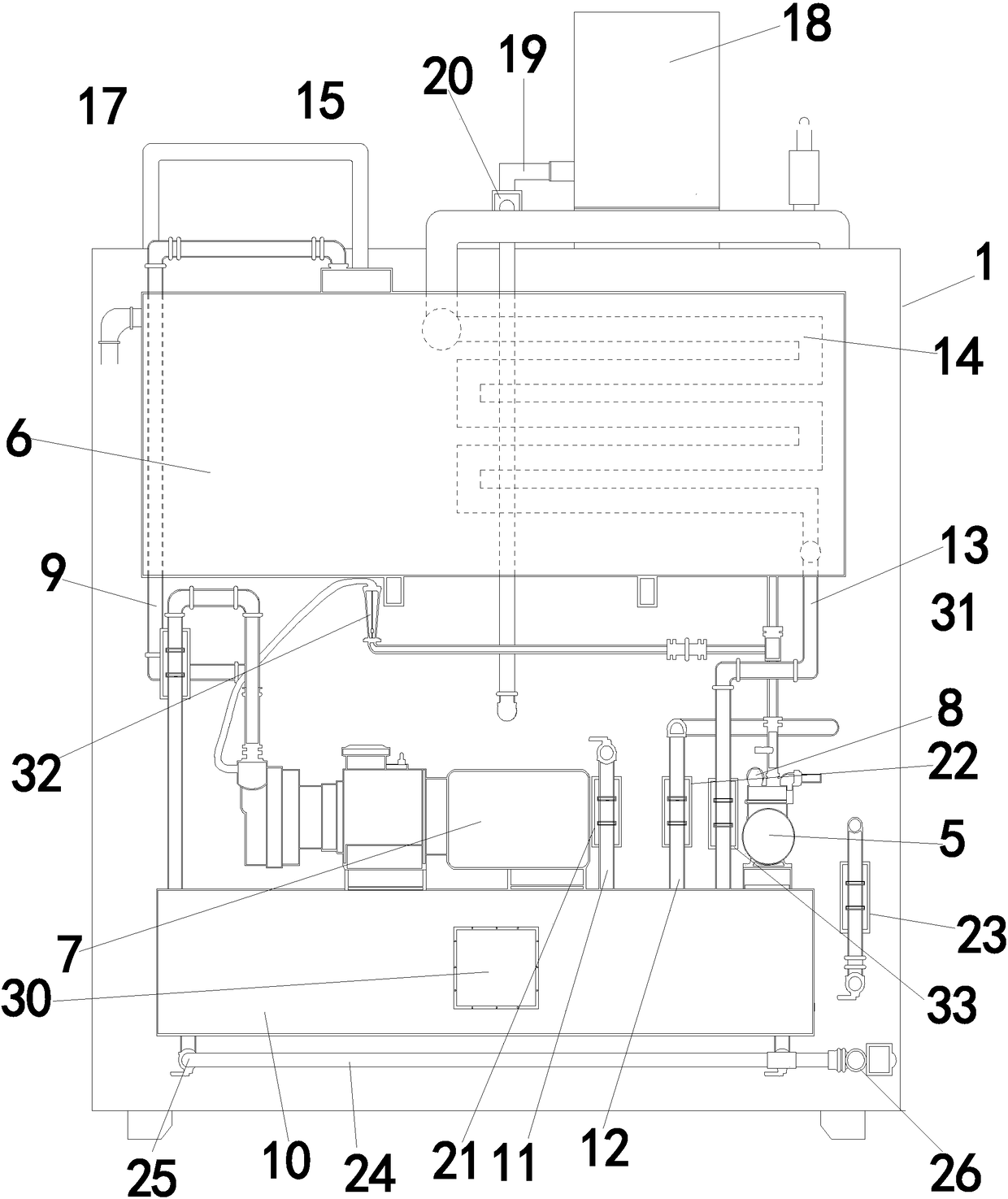

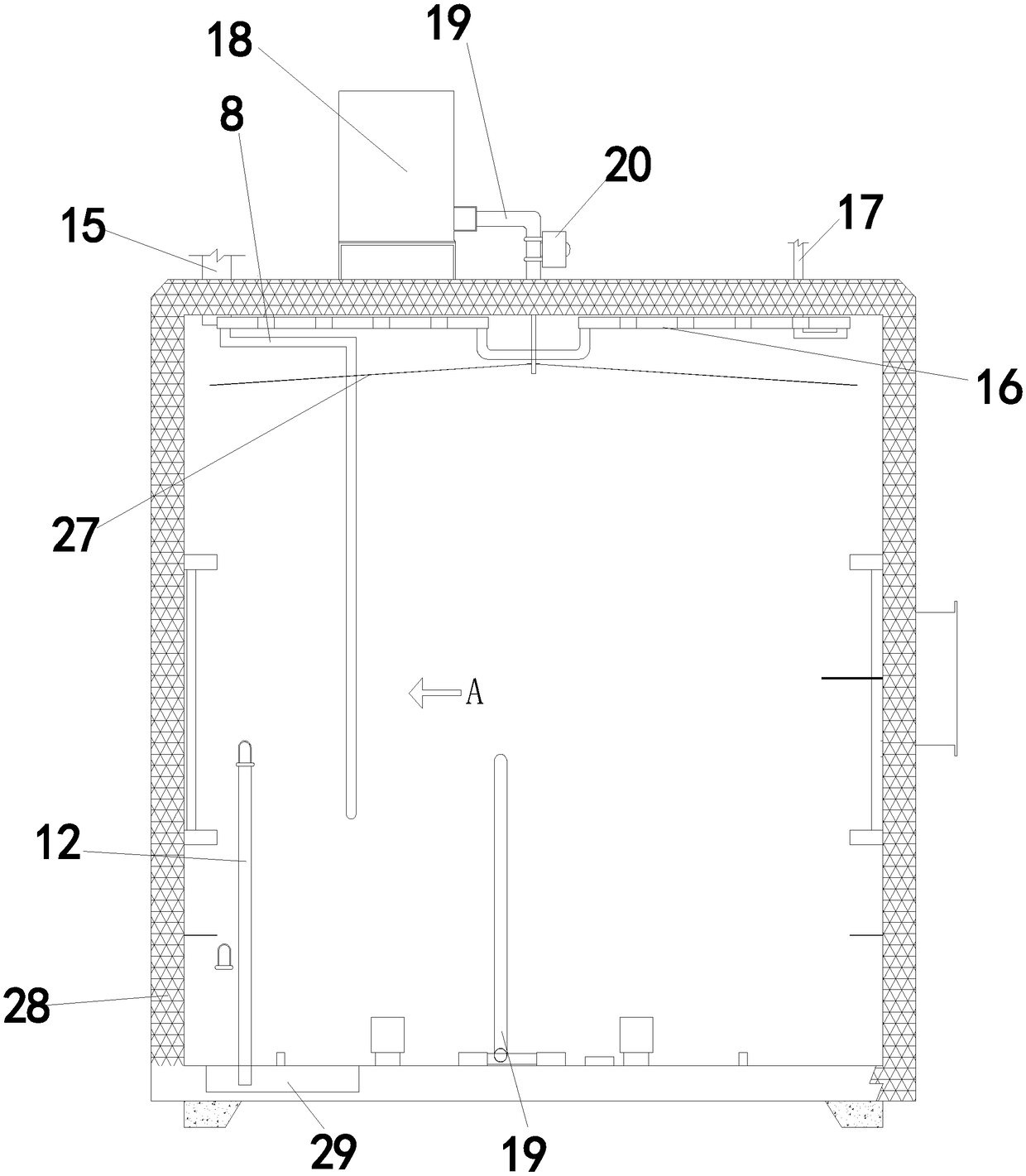

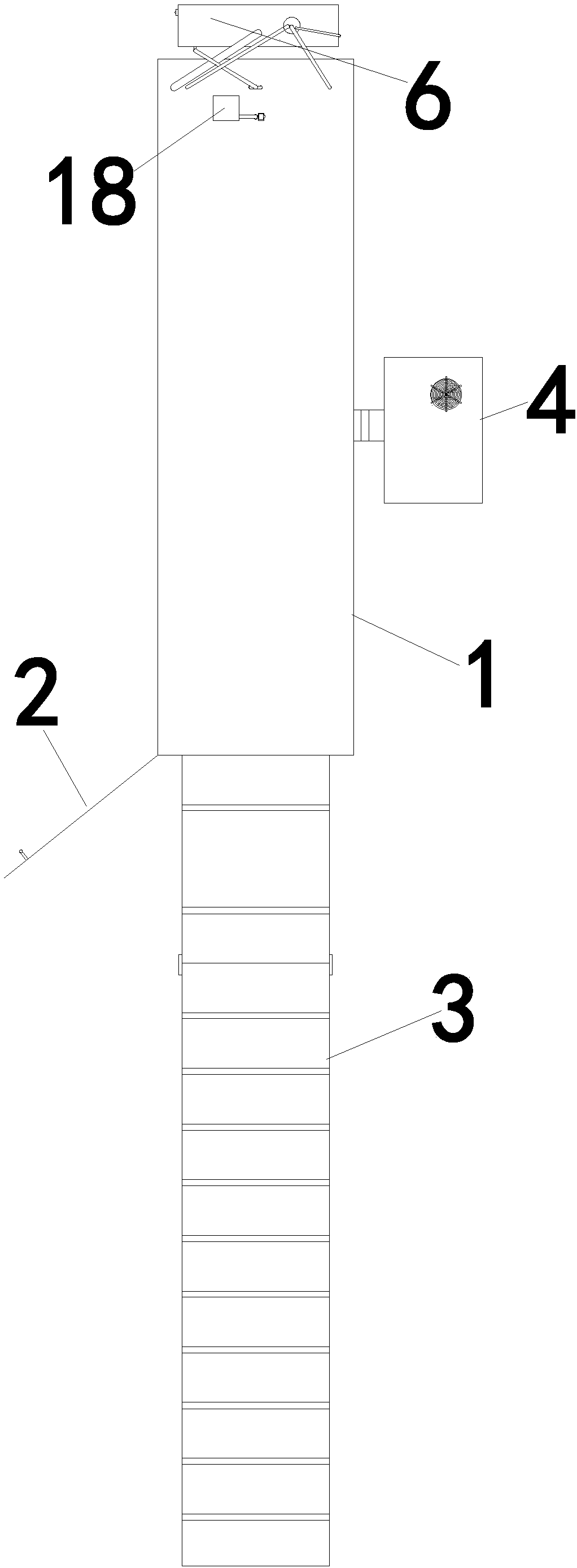

[0034] Such as Figure 1~3 As shown, a high-frequency steam vacuum drying box includes a box body. The box body adopts a front door, and a mobile wood car is arranged at the front door. system, the water circulation system includes a water circulation pump, the water circulation pump is respectively connected to the upper water tank, the vacuum pump and the condensate water inlet pipe through the pipeline; the vacuum pump is connected to the upper water tank through the vacuum pump exhaust pipe, and the vacuum pump is connected to the water collection tank through the pipeline; the upper water outlet of the upper water tank is connected to the cooling tower; The water collection tank is respectively equipped with a pressure relief pipe, a water suction pipe and an air suction pipe. The water suction pipe is inserted into the box body, the air suction pipe is connected to one end of the U-shaped pipe, the other end of the U-shaped pipe is connected to one end of the dehumidifica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com