A kind of hard tin-plated substrate for bottle cap and production method thereof

A technology of tin-plated substrate and production method, which is applied in the field of metallurgy, can solve the problems of large investment, high energy consumption, and decreased competitiveness of DR material products in continuous annealing production lines, and achieve the advantages of less difficulty in production control, stable performance, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

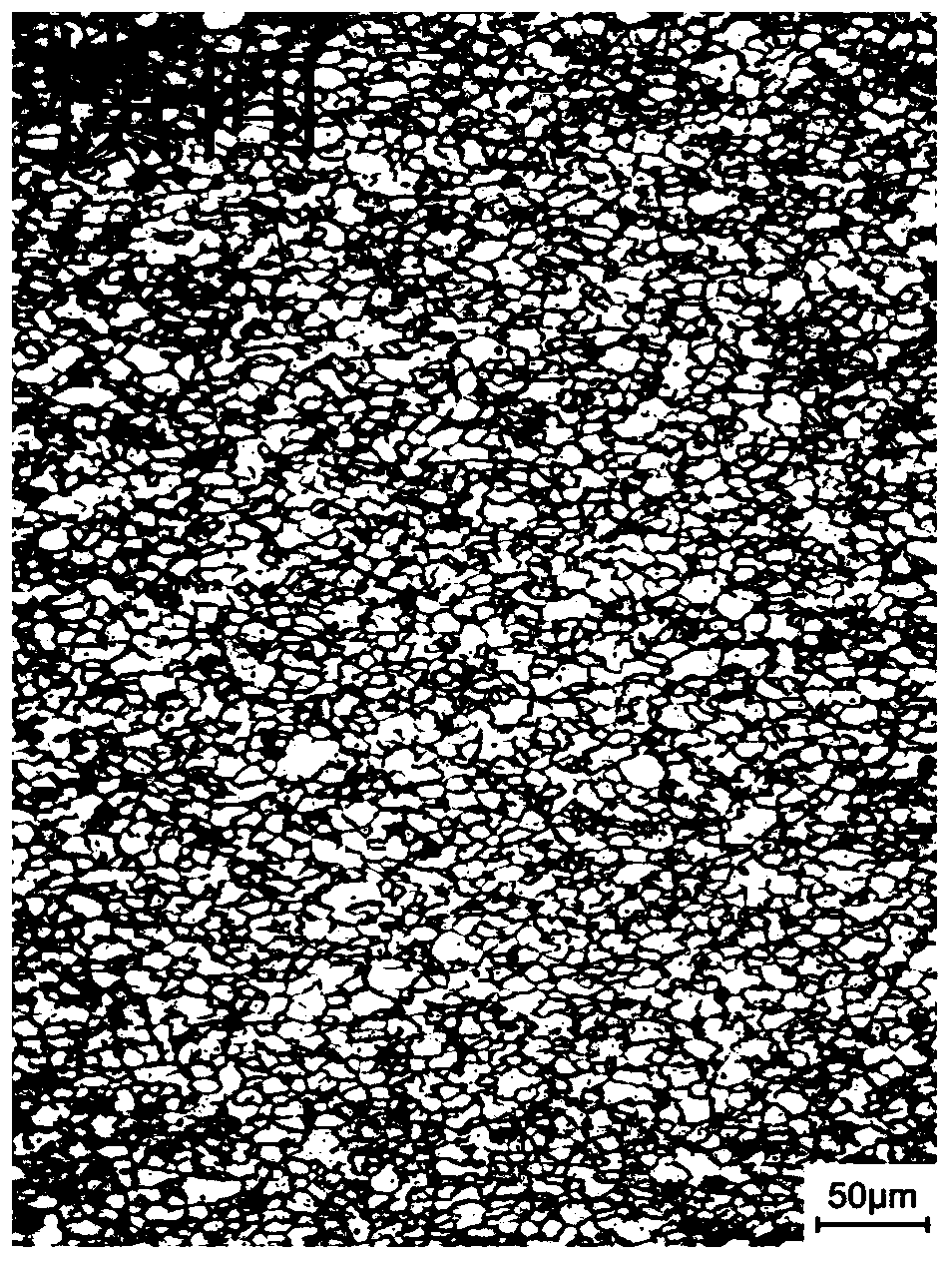

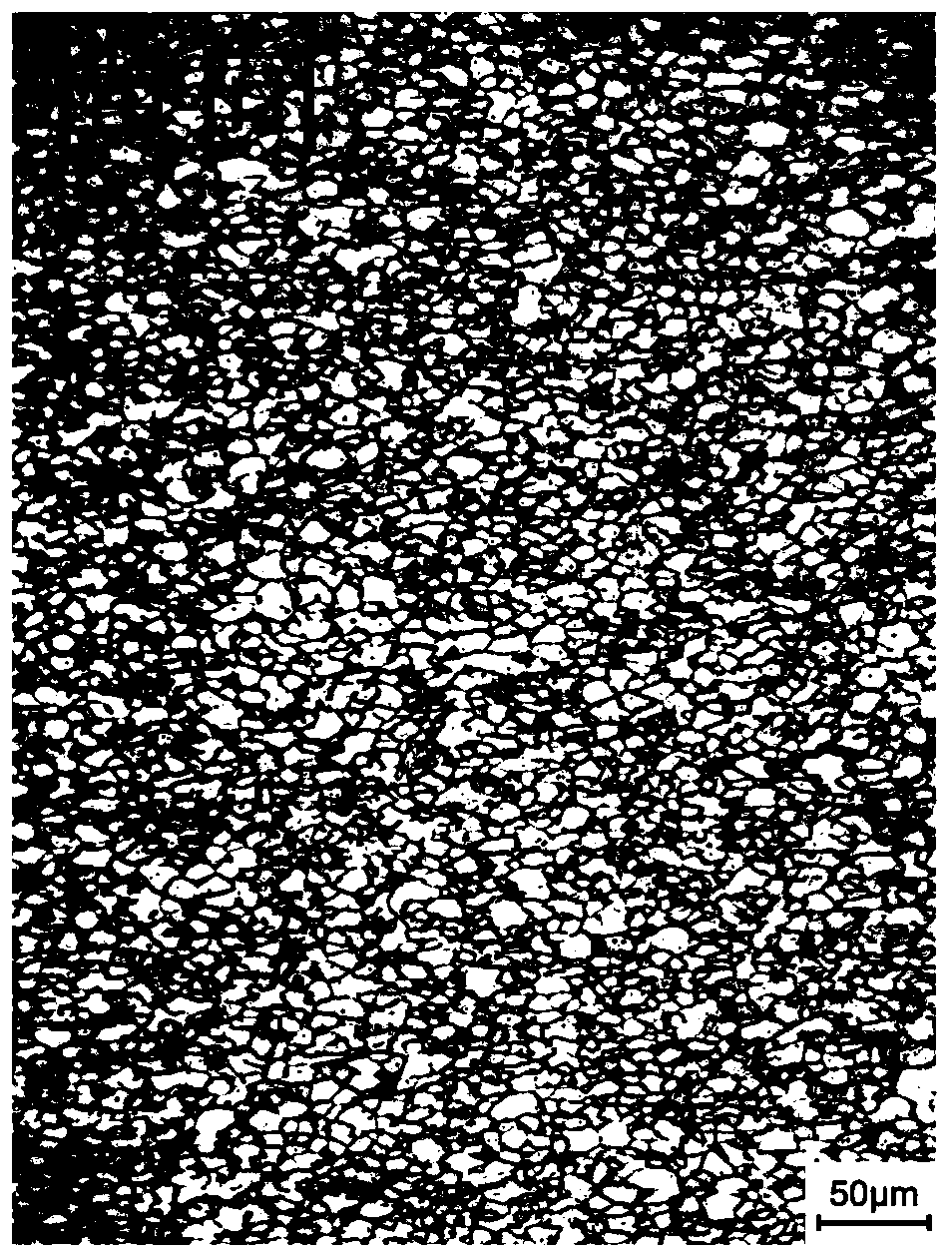

Image

Examples

Embodiment 1

[0038] A hard tin-plated substrate for bottle caps, the thickness of the finished product is 0.50mm, the chemical composition and mass percentage of the substrate are: C: 0.06%, Mn: 0.53%, Al: 0.02%, Si: 0.022%, N: 0.003%, S: 0.015%, P: 0.020%, and the balance is Fe and other unavoidable impurities.

[0039] A production method for a hard tin-plated substrate for bottle caps, the production method comprising smelting and refining, continuous casting, hot rolling, pickling, primary cold rolling, annealing, secondary cold rolling, and finishing processes, specific process steps As described below:

[0040] (1) The smelting process adopts converter smelting, fully decarburizes through top and bottom blowing, uses LF refining for deoxidation and desulfurization alloying, and uses RH refining to reduce the content of harmful gases N and H, N: 0.003%, H: 0.0001%, and then Continuous casting of slabs;

[0041] (2) Hot rolling process, 5 passes of rough rolling and 40mm thickness of...

Embodiment 2

[0049] A hard tin-plated substrate for bottle caps, the thickness of the finished product is 0.40mm, the chemical composition and mass percentage of the substrate are: C: 0.10%, Mn: 0.45%, Al: 0.08%, Si: 0.030%, N: 0.002%, S: 0.006%, P: 0.010%, and the balance is Fe and other unavoidable impurities.

[0050] A production method for a hard tin-plated substrate for bottle caps, the production method comprising smelting and refining, continuous casting, hot rolling, pickling, primary cold rolling, annealing, secondary cold rolling, and finishing processes, specific process steps As described below:

[0051] (1) The smelting process adopts converter smelting, fully decarburizes through top and bottom blowing, uses LF refining for deoxidation, desulfurization and alloying, and uses RH refining to reduce the content of harmful gases N and H, N: 0.002%, H: 0.0002%, and then Continuous casting of slabs;

[0052] (2) Hot rolling process, 5 passes of rough rolling and 38mm thickness o...

Embodiment 3

[0060] A hard tin-plated substrate for bottle caps, the thickness of the finished product is 0.30mm, the chemical composition and mass percentage of the substrate are: C: 0.07%, Mn: 0.30%, Al: 0.055%, Si: 0.015%, N: 0.005%, S: 0.001%, P: 0.008%, and the balance is Fe and other unavoidable impurities.

[0061] A production method for a hard tin-plated substrate for bottle caps, the production method comprising smelting and refining, continuous casting, hot rolling, pickling, primary cold rolling, annealing, secondary cold rolling, and finishing processes, specific process steps As described below:

[0062] (1) The smelting process adopts converter smelting, fully decarburizes through top and bottom blowing, uses LF refining for deoxidation and desulfurization alloying, and uses RH refining to reduce the content of harmful gases N and H, N: 0.005%, H: 0.0003%, and then Continuous casting of slabs;

[0063] (2) Hot rolling process, 5 passes for rough rolling, intermediate bille...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com