A method for enrichment and separation of vanadium-titanium magnetite

A vanadium-titanium magnetite enrichment technology, which is applied in the direction of improving process efficiency, can solve the problem of low Ti grade in magnetic separation tailings, and achieve the effect of avoiding high equipment requirements, stable equipment operation, and efficient capture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

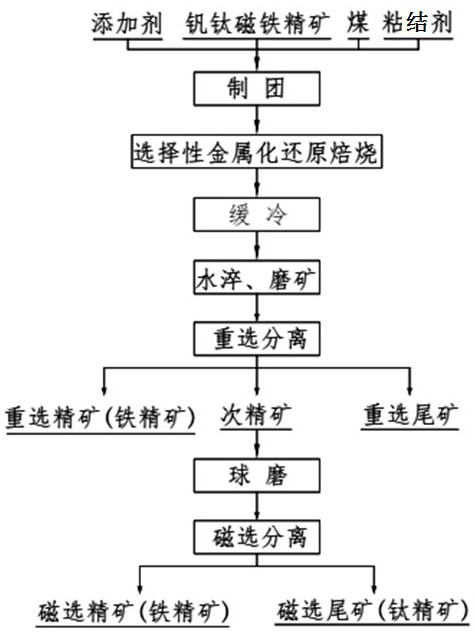

Image

Examples

Embodiment 1

[0036] Take 1000g vanadium-titanium magnetite concentrate (TFe 53%, TiO 213.4%), mixed with 30gNaCl, 20gCaO, and 300g coal powder and mixed evenly. Among them, the particle size of vanadium titanomagnetite powder was 0.9mm, and the particle size of coal powder was 1.9mm. Add 200mL of polyacrylamide solution with a mass concentration of 1.5‰ as a The pellets were made into pellets, and the pellets were roasted at a constant temperature of 1000°C for 2 hours, then heated to 1200°C, roasted at a constant temperature for 3 hours, and the produced roasted balls were gradually cooled to 750°C for 6 hours, and then quenched and quenched in water after slow cooling, and the output of roasted balls was 830g; Baking ball crushing and ball milling, 75% of the particle size is less than 74μm, gravity separation on the slurry shaker, and 346g of gravity-selected iron concentrate (Fe 92.71%, TiO 2 2.07%), secondary concentrate 321g (Fe51.49%, TiO 2 28.32%) and gravity separation tailings...

Embodiment 2

[0038] Take 1000g vanadium-titanium magnetite concentrate (TFe 53%, TiO 2 13.4%), mixed with 40gCaCl 2 , 30gNa 2 CO 3 , 320g coal powder and mix well, wherein, vanadium-titanium magnetite ore powder particle size is 0.85mm, coal powder particle size is 1.8mm, add 30g sodium humate as binder to granulate, pellets are roasted at 1050°C for 1 hour and then heated to 1300°C, constant temperature roasting for 2 hours, the produced roasted balls were gradually cooled to 800°C for 8 hours, and then quenched and quenched in water after slow cooling, and the output roasted balls were 847g; the roasted balls were crushed and ball milled, and the particle size was less than 74μm, accounting for 68%. Separation, output gravity separation concentrate 415.5g (Fe 93.84%, TiO 2 1.02%), secondary concentrate 284g (Fe43.7%, TiO 2 31.73%) and tailings 147g (Fe 12.9%, TiO 2 26.24%); the sub-concentrate was ball milled again, and the particle size was less than 74μm, accounting for 92%, a...

Embodiment 3

[0040] Take 1000g vanadium-titanium magnetite (TFe 45%, TiO 2 24.5%), mixed with 40gKCl, 10gCaF 2 , 225g of coal powder and mix well, add 40g of asphalt as a binder to granulate, the pellets are roasted at a constant temperature of 1000°C for 1.5h, then heated to 1230°C, roasted at a constant temperature for 2.5h, and the baked balls produced are gradually cooled to 770°C for 5h. After slow cooling, water quenching and rapid cooling produced 860g of roasted balls; the roasted balls were crushed and ball milled, and the particle size was less than 74μm, accounting for 69%. 2 1.89%), secondary concentrate 394g (Fe 37.2%, TiO 2 49.72%) and tailings 158g (Fe 11.72%, TiO 2 27.38%); the sub-concentrate was ball milled again, and the particle size was less than 74μm, accounting for 91.2%. 2 2.13%), titanium concentrate 251.2g (Fe17.28%, TiO 2 76.8%); the iron enrichment rate of iron concentrate is 92%, and the titanium enrichment rate of titanium concentrate is 78%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com