Method for preparing metal sulfur group compound semiconductor ultrafine ultra-long nano-wires, and nano-wires prepared through method

A compound and semiconductor technology, used in metal selenide/telluride, selenium/tellurium compounds, chemical instruments and methods, etc., to achieve good crystallinity, wide application value, and remarkable quantum confinement effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

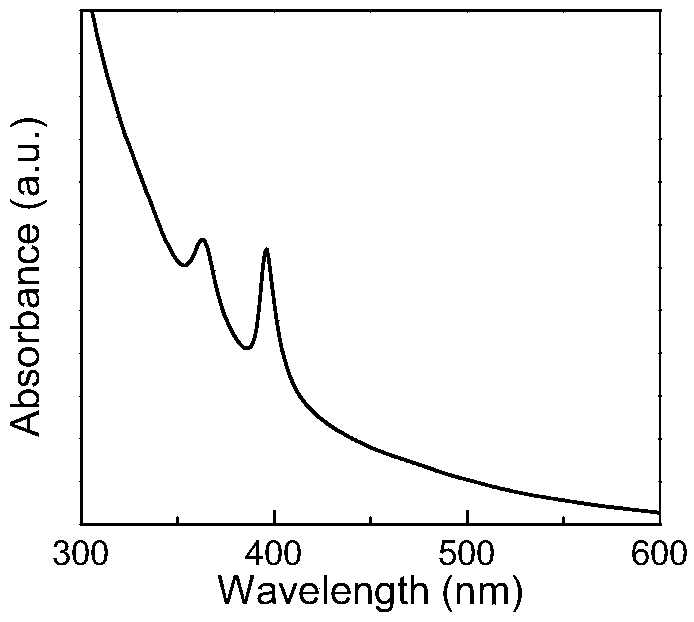

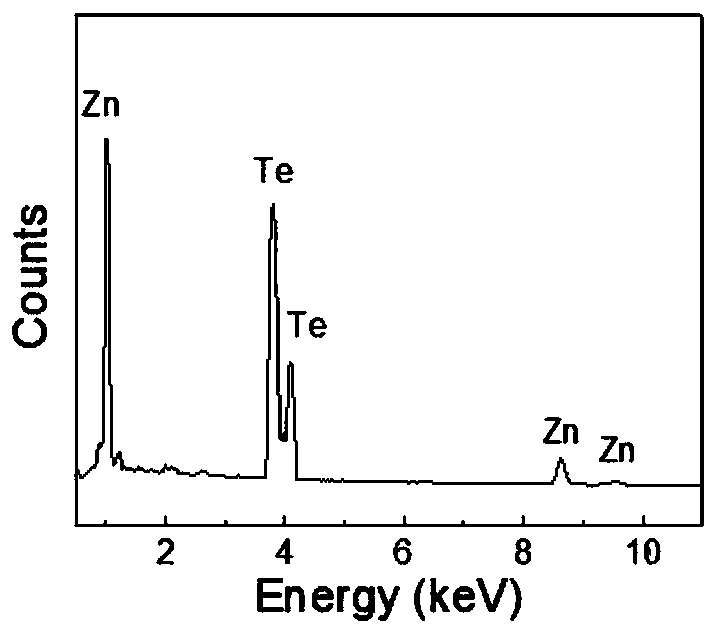

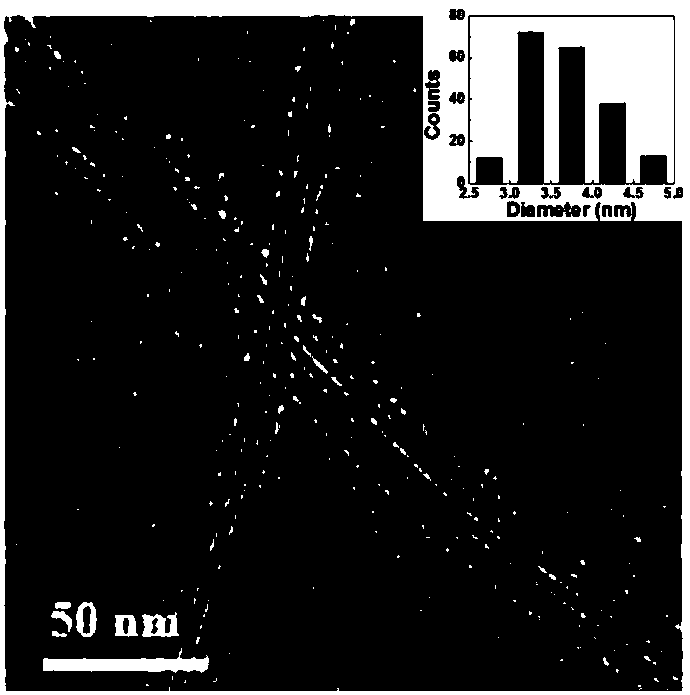

[0041] Embodiment 1, the preparation of ZnTe nanowires with an average diameter of 3.5nm

[0042] (1) Preparation of zinc precursor: 0.2~1.0mmol Zn(NO 3 ) 2 or ZnCl 2 Mix it with 6.0-15mL of octylamine or oleylamine or tri-n-octylphosphine oxide and add it to the container. Under the protection of inert gas, stir and heat until clear, and then the solution drops to room temperature, that is, the zinc precursor solution.

[0043] Among them, Zn(NO 3 ) 2 or ZnCl 2 The amount is 0.2-1.0 mmol, the amount of octylamine or oleylamine or tri-n-octylphosphine oxide is 6.0-15 mL, and the molar ratio of the metal precursor to the organic ligand is 1:20-50.

[0044] (2) Preparation of tellurium precursor: add 0.1-1.0 mmol tellurium powder or tellurium dioxide or sodium tellurite and 1.0-2.0 mL tri-n-octylphosphine or tri-n-butylphosphine into a container filled with argon or nitrogen , the mixture was stirred and heated until clear, and cooled to room temperature, that is, the prec...

Embodiment 2

[0047] Embodiment 2, the average diameter is the preparation of the CdTe nanowire of 4.8nm

[0048] The choice of cadmium removal precursor is 0.2~1.0mmol Cd(Ac) 2 or Cd(NO 3 ) 2 Except, other synthesis steps are the same as in Example 1. Such as Figure 4 Shown is the absorption spectrum of the CdTe nanowires prepared in Example 5. from Image 6 It can be known from the composition analysis that its constituent elements are Cd and Te. Figure 7 with Figure 8 It is the transmission electron microscope picture of CdTe nanowire, as can be seen from the figure that the CdTe nanowire prepared by the method of the present invention is an ultrafine nanowire, the average length of the nanowire is about 7 μm, and the average diameter is 4.8nm, and its aspect ratio About 1400:1.

Embodiment 3

[0049] Embodiment 3, the preparation of the ZnSe nano wire that average diameter is 3.4nm

[0050] The choice of selenium removal precursor is 0.1 ~ 1mmol selenium powder or selenourea or selenium dioxide and 1 ~ 2mL C 8 ~C 18 Except that alkylamine is used as an activator, other synthesis steps are the same as in Example 1. Such as Figure 9 Shown is the absorption spectrum of the ZnSe nanowires prepared in Example 3. from Figure 10 It can be known from the composition analysis that its constituent elements are Zn and Se. Figure 11 with Figure 12 It is the transmission electron microscope figure of ZnSe nanowire, as can be seen from the figure that the ZnSe nanowire prepared by the inventive method is an ultrafine nanowire, and the average length of the nanowire is about 5 μm, and the average diameter is 3.4nm, and its aspect ratio About 1400:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com