Microfluidic device with multiple temperature zones

A technology of temperature zone and temperature control components, applied in the field of active matrix array and its components, can solve the problems of increasing the complexity and cost of the manufacturing process, limiting the range of operation, etc., to promote rapid thermal cycle, reduce time, and reduce the cost of devices cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

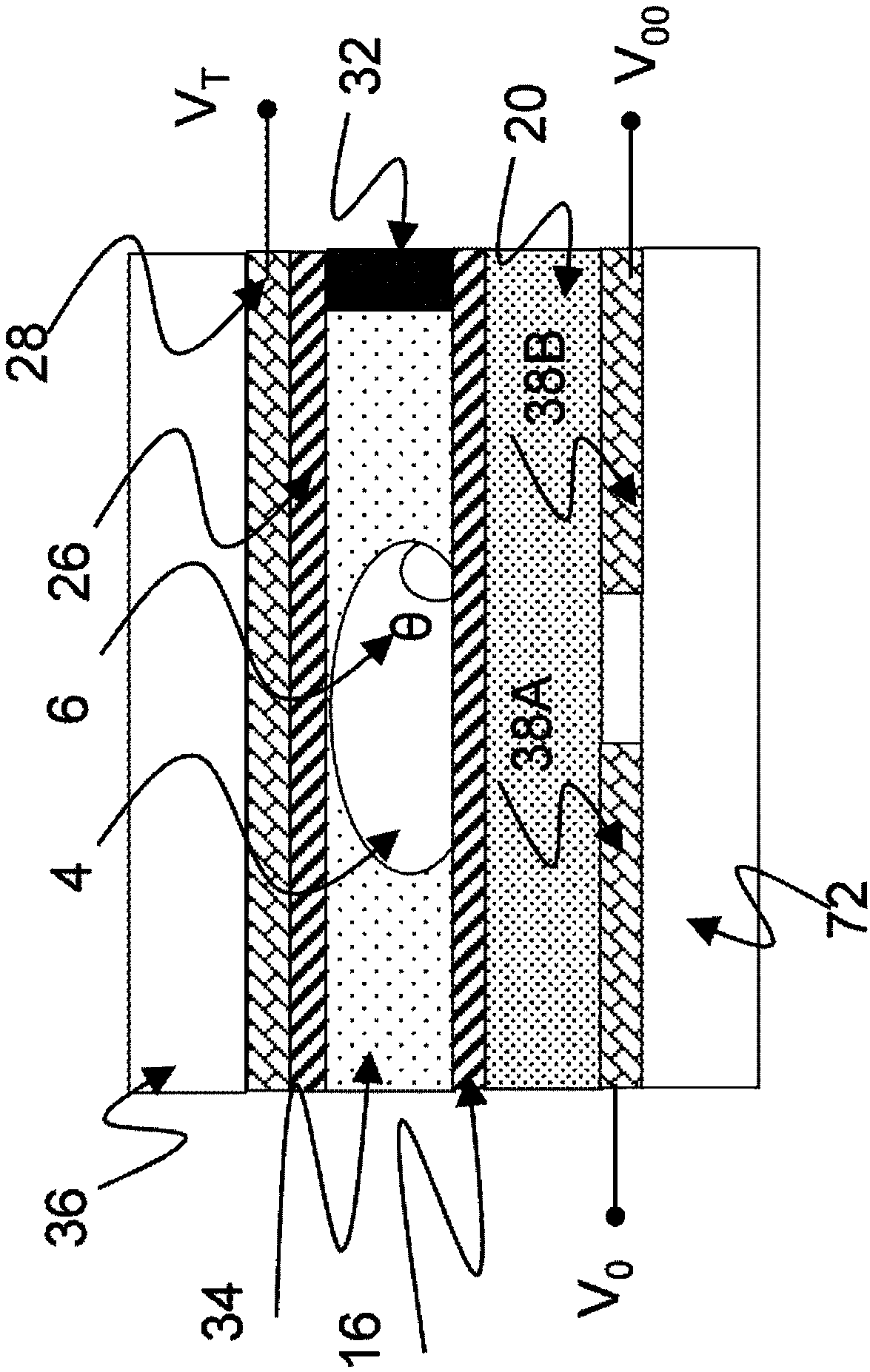

[0098] figure 2 with 3(a) An exemplary droplet microfluidic processing system according to the first embodiment of the present invention is shown. The system is divided into two parts, including a box 49 and a reader 40.

[0099] The box body 49 is shown as including the EWOD device 41 and is modularized into, for example, a plastic casing. For example, the module may include an upper plastic part 42 and a lower plastic part 44, although this is a matter of design and many arrangements are possible. Generally, the box 49 includes an input structure 46 (for example, a hole) for inputting fluid, and may optionally include an output structure 48, whereby the liquid can be ejected from the device. The input and output structure is fluidly connected to the fluid gap 35 so that fluid can be input to / output from the EWOD device. EWOD devices generally contain a distribution structure for generating droplets 4 in the fluid gap, for example by electrowetting. Generally, the cassette ca...

no. 2 example

[0137] Figure 5 A second embodiment of the present invention is shown in. The second embodiment is an extension of the first embodiment, in which the internal temperature control elements 52a, 52b of FIG. 3(a) are replaced by external temperature control elements 54a, 54b. These external temperature control elements may be located within the reader 40 or, alternatively, may be fixed to the outer surface of the substrate 36. Similarly, these external temperature control elements 50a, 50b may be located within the reader 40, or alternatively, may be fixed to the outer surface of the lower substrate 72.

[0138] Since the temperature control element is not included in the EWOD device (that is, the temperature control element is included between the upper substrate and the lower substrate), the advantage of this embodiment is that the design of the EWOD device 41 is simplified. In the second embodiment, the temperature control elements of both the upper substrate and the lower subst...

no. 3 example

[0141] Image 6 The third embodiment of the invention shown in is an extension of either of the first or second embodiment, in which an additional temperature control element 56 is provided on the upper substrate 36. The additional temperature control element 56 may be a heat source or a heat sink, and may be controllable independently of the first and second sets of temperature control elements. The purpose of the additional temperature control element is to provide further control over the offset temperature of the device or the temperature of the droplet that is greater or lower than the ambient temperature. This embodiment includes any combination of internal additional temperature control elements and external additional temperature control elements on the upper substrate 36 or the lower substrate 72.

[0142] In this embodiment, as described above, the shape of the temperature distribution created in the fluid gap is still determined by the balance of the heat flow from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com