Preparation method of manganese-doped lithium iron phosphate electrode material

A technology of lithium iron phosphate and electrode materials, which is applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of uneven mixing of solid-phase raw materials, many impurities in products, and poor cycle stability, and achieve ideal electrochemical performance and process Simple, great economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

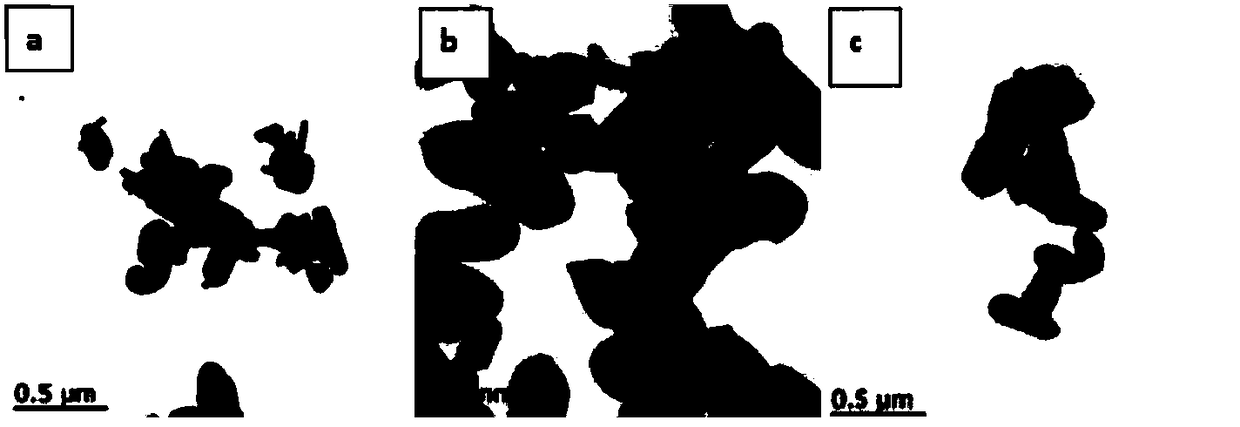

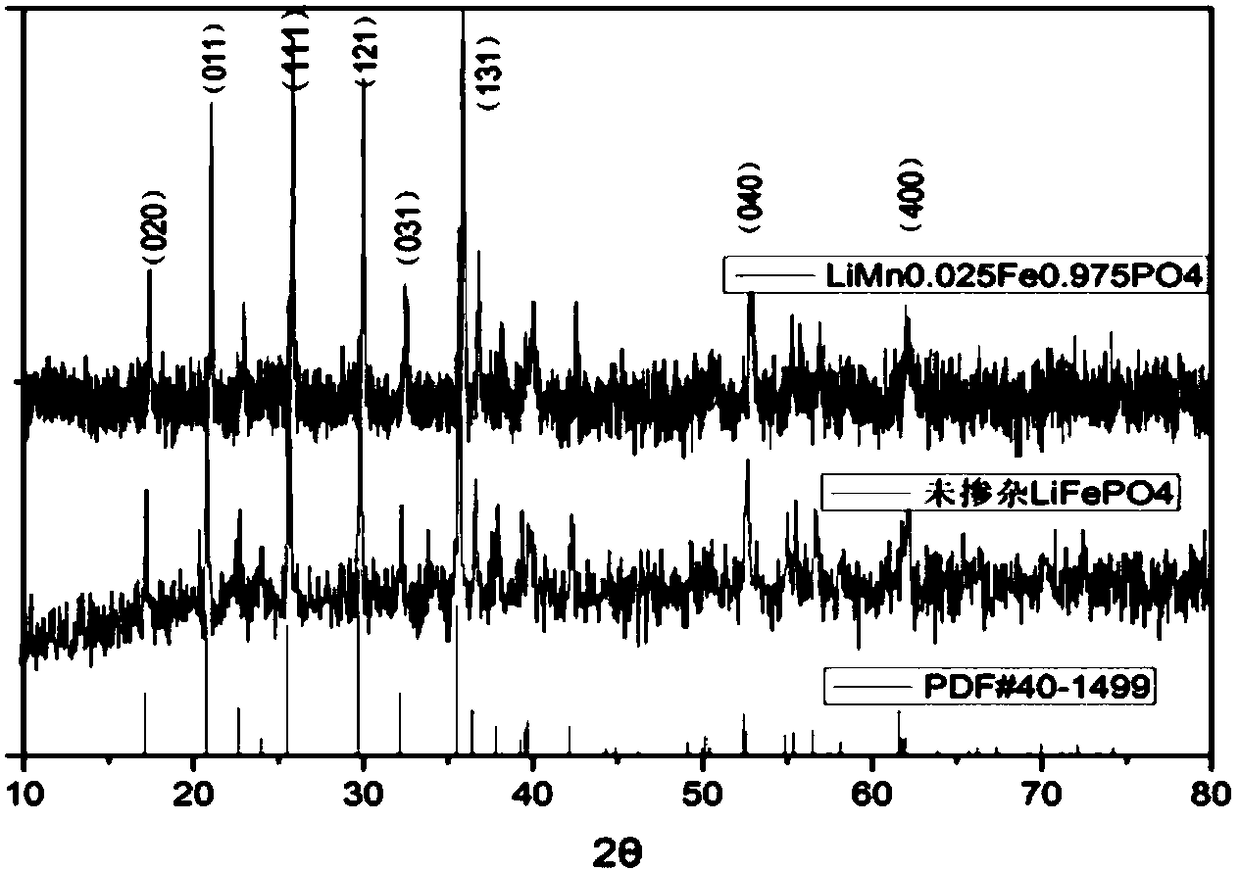

Image

Examples

Embodiment 1

[0025] LiMn 0.025 Fe 0.975 PO 4 Prepared by the following steps:

[0026] (1) Preparation of LiFePO by stirring precipitation method 4 Precursor: 2.49g of phosphoric acid, 7.06g of ferrous sulfate heptahydrate, 3.2g of lithium hydroxide monohydrate, and 0.2g of ascorbic acid were weighed according to the molar ratio of 1:1:3 and prepared into aqueous solutions respectively. Add phosphoric acid to the lithium hydroxide solution to form a white precipitate, measure 50mL of ethylene glycol, mix with ascorbic acid and ferrous sulfate, add drop by drop to lithium phosphate to form a light green precipitate, keep stirring, and there is nitrogen in the solution slowly Blowing to remove oxygen dissolved in water;

[0027] (2) Add Mn source dropwise for Mn doping: Weigh 0.11g of manganese sulfate monohydrate, configure it into an aqueous solution, slowly add it dropwise into the precursor solution, keep stirring for 0.5h, and slowly blow nitrogen into the solution;

[0028] (3) Op...

Embodiment 2

[0031] LiMn 0.015 Fe 0.985 PO 4 Prepared by the following steps:

[0032] (1) Preparation of LiFePO by stirring precipitation method 4 Precursors: 2.49g of phosphoric acid, 7.06g of ferrous sulfate heptahydrate, 3.2g of lithium hydroxide monohydrate, and 0.2g of ascorbic acid were weighed according to the molar ratio of 1:1:3 and prepared into aqueous solutions respectively. Add phosphoric acid to lithium hydroxide solution to form a white precipitate, measure 50mL of ethylene glycol, ascorbic acid and ferrous sulfate, add drop by drop to lithium phosphate to form a light green precipitate, keep stirring, and there is nitrogen in the solution slowly Blowing to remove oxygen dissolved in water;

[0033] (2) Add Mn source dropwise for Mn doping: Weigh 0.064g of manganese sulfate monohydrate, configure it into an aqueous solution, slowly add it dropwise into the precursor solution, keep stirring for 0.5h, and slowly bubble nitrogen into the solution;

[0034] (3) Optimal gro...

Embodiment 3

[0037] LiMn 0.035 Fe 0.965 PO 4 Prepared by the following steps:

[0038] (1) Preparation of LiFePO by stirring precipitation method 4 Precursors: 2.49g of phosphoric acid, 7.06g of ferrous sulfate heptahydrate, 3.2g of lithium hydroxide monohydrate, and 0.2g of ascorbic acid were weighed according to the molar ratio of 1:1:3 and prepared into aqueous solutions respectively. Add phosphoric acid to lithium hydroxide solution to form a white precipitate, measure 50mL of ethylene glycol, ascorbic acid and ferrous sulfate, add drop by drop to lithium phosphate to form a light green precipitate, keep stirring, and there is nitrogen in the solution slowly Blowing to remove oxygen dissolved in water;

[0039] (2) Add Mn source dropwise for Mn doping: Weigh 0.15g of manganese sulfate monohydrate, configure it into an aqueous solution, slowly add it dropwise into the precursor solution, keep stirring for 0.5h, and slowly blow nitrogen into the solution;

[0040] (3) Optimal growth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| ionic conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com