Three-dimensional porous carbon/polythionine compound modified electrode, and production method and application thereof

A three-dimensional porous and modified electrode technology, which is applied in the field of chemical analysis and detection, can solve the problems of time-consuming operation and complexity, and achieve the effect of maintaining stability, good adsorption capacity, and accelerating the electron transfer rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Example 1: Preparation of three-dimensional porous carbon / polythionine composite modified electrode

[0040] S1: Preparation of anodized electrode

[0041] Use 0.5μm Al on polishing nap pads 2 o 3 The polishing powder is used to polish the glassy carbon electrode with a diameter of 2 mm. After polishing, it is rinsed with ultrapure water, and then ultrasonically cleaned in ethanol and water in sequence.

[0042] The electrolytic cell is filled with a phosphate buffer solution with a concentration of 0.1mol / L and a pH of 7.0. The above-mentioned treated glassy carbon electrode is used as a working electrode, a platinum wire electrode is used as an auxiliary electrode, and a saturated calomel electrode is used as a reference electrode. On the electrochemical workstation, run for 200s under the condition of a voltage of 1.8V, take out the working electrode and fully rinse it with ultrapure water to obtain an anodic oxidation electrode.

[0043] S2: Preparation of Polyth...

Embodiment 2

[0048] Embodiment 2: Comparative experiment of different electrodes

[0049] (1) Preparation of three-dimensional porous carbon modified electrodes

[0050] Use 0.5μm Al on polishing nap pads 2 o 3 The polishing powder is used to polish the glassy carbon electrode with a diameter of 2 mm. After polishing, it is rinsed with ultrapure water, and then ultrasonically cleaned in ethanol and water in sequence. Then, 2.0 μL of the three-dimensional porous carbon dispersion described in Step S3 of Example 1 was drip-coated, and dried under an infrared lamp to obtain a three-dimensional porous carbon-modified electrode.

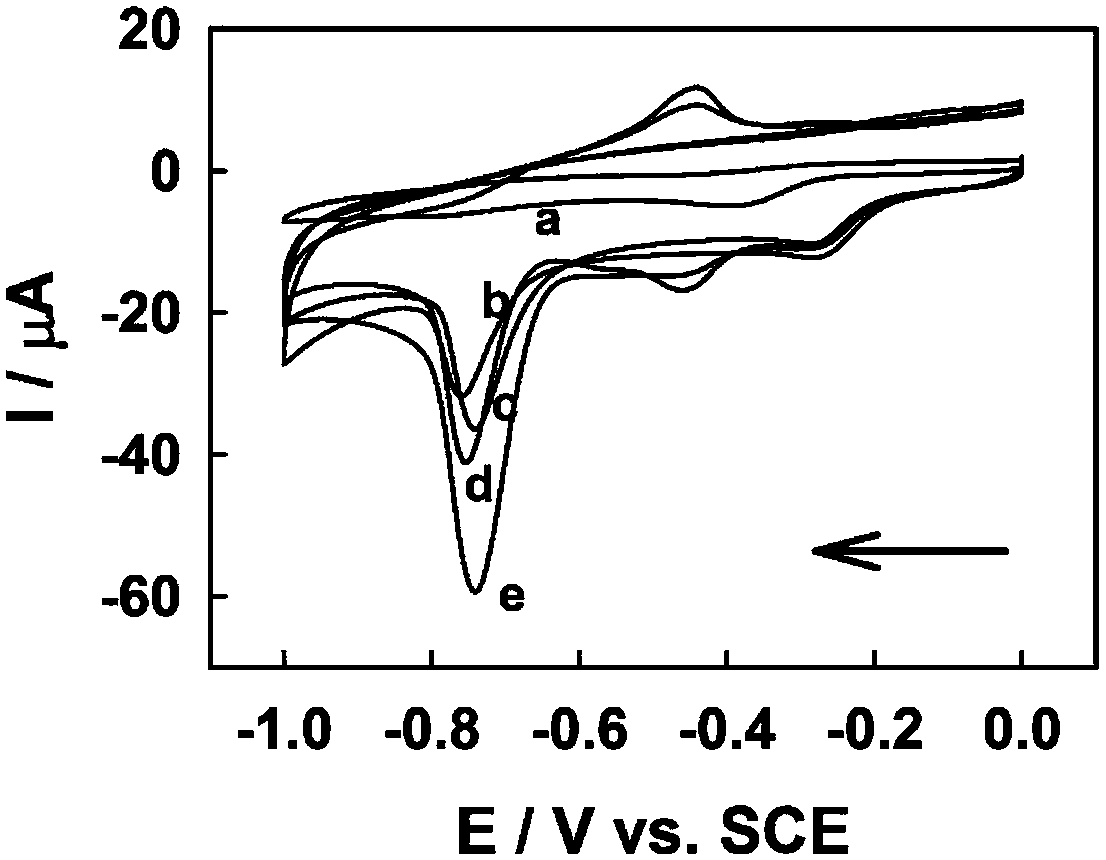

[0051] (2) With the phosphate buffer containing 100 μmol / L metronidazole as the electrolyte, the phosphate concentration in the phosphate buffer is 0.1mol / L, the pH is 11.0, the bare glassy carbon electrode is the working electrode, and the platinum wire The electrode is the auxiliary electrode, and the saturated calomel electrode is the reference electrode, which ...

Embodiment 3

[0054] Embodiment 3: Detect metronidazole content in medicine

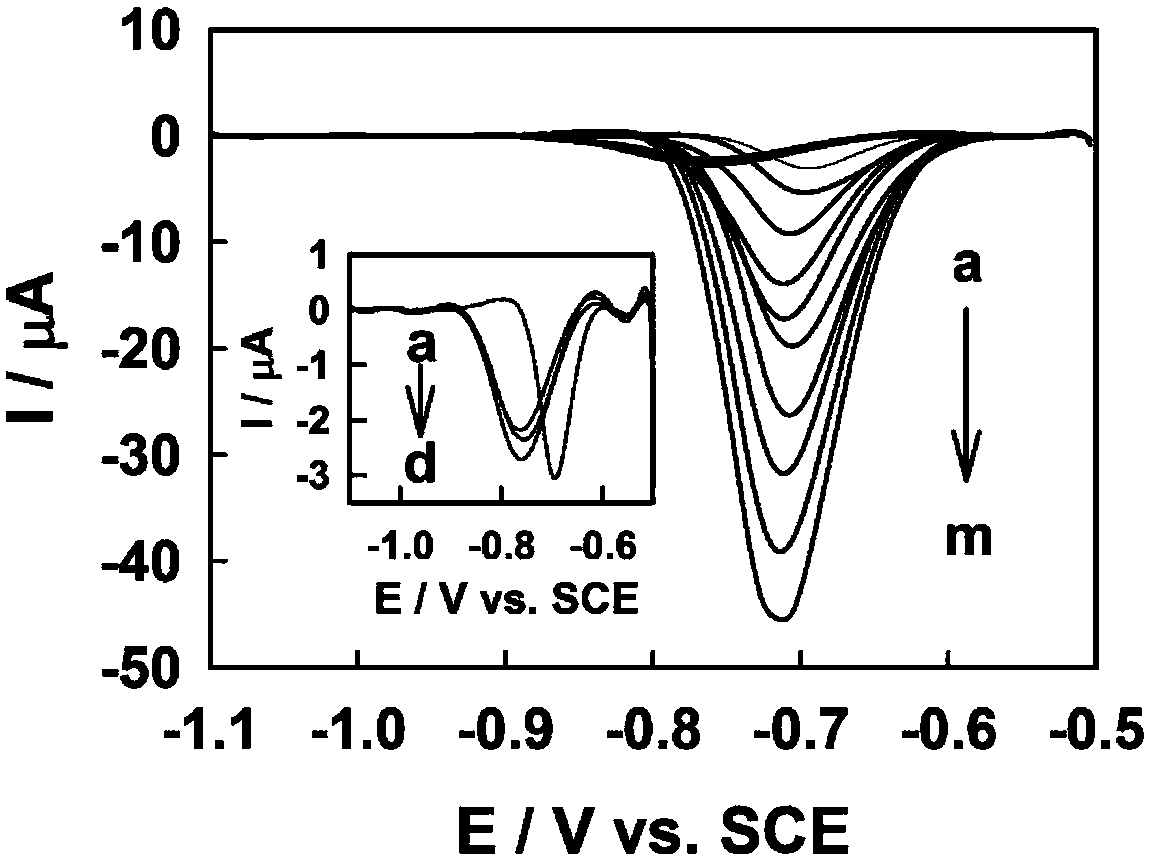

[0055] (1) Dissolve metronidazole in a phosphate buffer solution with a concentration of 0.1mol / L and a pH of 11.0, and prepare a series of concentrations of 0.05, 0.1, 1, 5, 10, 30, 50, 70, 100, 200, 300, 400 and 500 μmol / L metronidazole standard solutions.

[0056] The three-dimensional porous carbon / polythionine composite modified electrode was used as the working electrode, the platinum wire electrode was used as the auxiliary electrode, and the saturated calomel electrode was used as the reference electrode. The reduction of metronidazole in the standard solution of metronidazole was determined by differential pulse voltammetry. Differential pulse voltammograms of standard solutions of metronidazole with different concentrations on the three-dimensional porous carbon / polythionine composite modified electrode were obtained. Read the reduction peak current whose voltage is around -0.71V in the differential pul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com