Konjac glucomannan air purifying nano screen window and preparation method thereof

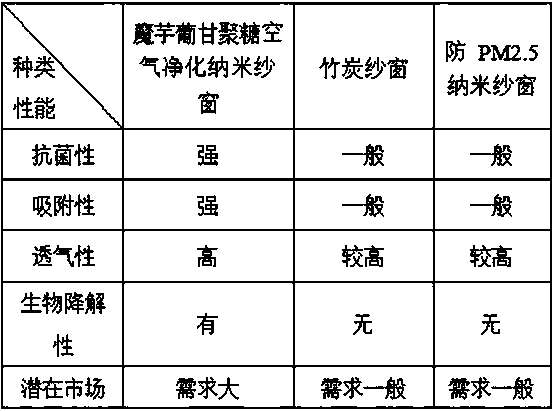

A konjac glucomannan, air purification technology, applied in textiles and papermaking, fiber treatment, insect control and other directions, can solve the problems of screen windows not adapting to the needs of the times, affecting physical health, not being able to prevent rain and water, and improving weather resistance. Ability, high tensile strength, easy to obtain the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1 A kind of preparation method of konjac glucomannan air purification nano screen window, comprises the following steps:

[0025] (1) Membrane-making stock solution: prepared according to the mass parts, after heating 50 parts of polypropylene and 50 parts of polyurethane as a fluxing agent into a molten state, at 50 o C was mechanically stirred at a speed of 800r / min for 1h, and then centrifuged at 3000r / min for 5min to remove air bubbles to obtain a film-forming stock solution;

[0026] (2) Production of non-woven fabrics: The film stock solution prepared in step (1) is uniformly cast on a 40×50 cm concave glass film template to form a film, and dried in a vacuum oven at 55°C for 30 hours to obtain a synthetic film. Polymer reinforced non-woven fabric;

[0027] (3) Making spinning solution: Weigh 0.3 parts of nano-cobalt ferrite and add it to 99 parts of water, ultrasonically disperse for 30 minutes, and then o C, stirring at 350r / min for 20 min, adding 0...

Embodiment 2

[0029] Embodiment 2 A kind of preparation method of konjac glucomannan air purification nano screen window, comprises the following steps:

[0030] (1) Membrane-making stock solution: Prepared according to the number of parts by mass. After heating 60 parts of polypropylene and 40 parts of polyurethane as a fluxing agent into a molten state, o C was mechanically stirred at a speed of 800r / min for 1h, and then centrifuged at 3000r / min for 5min to remove air bubbles to obtain a film-forming stock solution;

[0031] (2) Making non-woven fabrics: Spread the film stock solution prepared in step (1) evenly on a concave glass film template to form a film, and dry it in a vacuum oven at 58°C for 40 hours to obtain a synthetic polymer reinforcement. of non-woven fabrics;

[0032] (3) Making spinning solution: Weigh 0.5 parts of nano-cobalt ferrite and add it to 99 parts of water, ultrasonically disperse for 30 minutes, and then o C, stirring at 350r / min for 20 min, adding 1 part of k...

Embodiment 3

[0034] Embodiment 3 A kind of preparation method of konjac glucomannan air purification nano screen window, comprises the following steps:

[0035] (1) Membrane-making stock solution: Prepared according to the number of parts by mass. After heating 70 parts of polypropylene and 30 parts of polyurethane as fluxing agent into a molten state, oC was mechanically stirred at a speed of 800r / min for 1h, and then centrifuged at 3000r / min for 5min to remove air bubbles to obtain a film-forming stock solution;

[0036] (2) Production of non-woven fabrics: The film stock solution prepared in step (1) was uniformly cast on a 40×50 cm concave glass film template to form a film, and dried in a vacuum oven at 60°C for 48 hours to obtain a synthetic film. Polymer reinforced non-woven fabric;

[0037] (3) Making spinning solution: Weigh 0.7 parts of nano-cobalt ferrite and add it to 99 parts of water, ultrasonically disperse for 30 minutes, and then o C, stirred at 350r / min for 20 min, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com