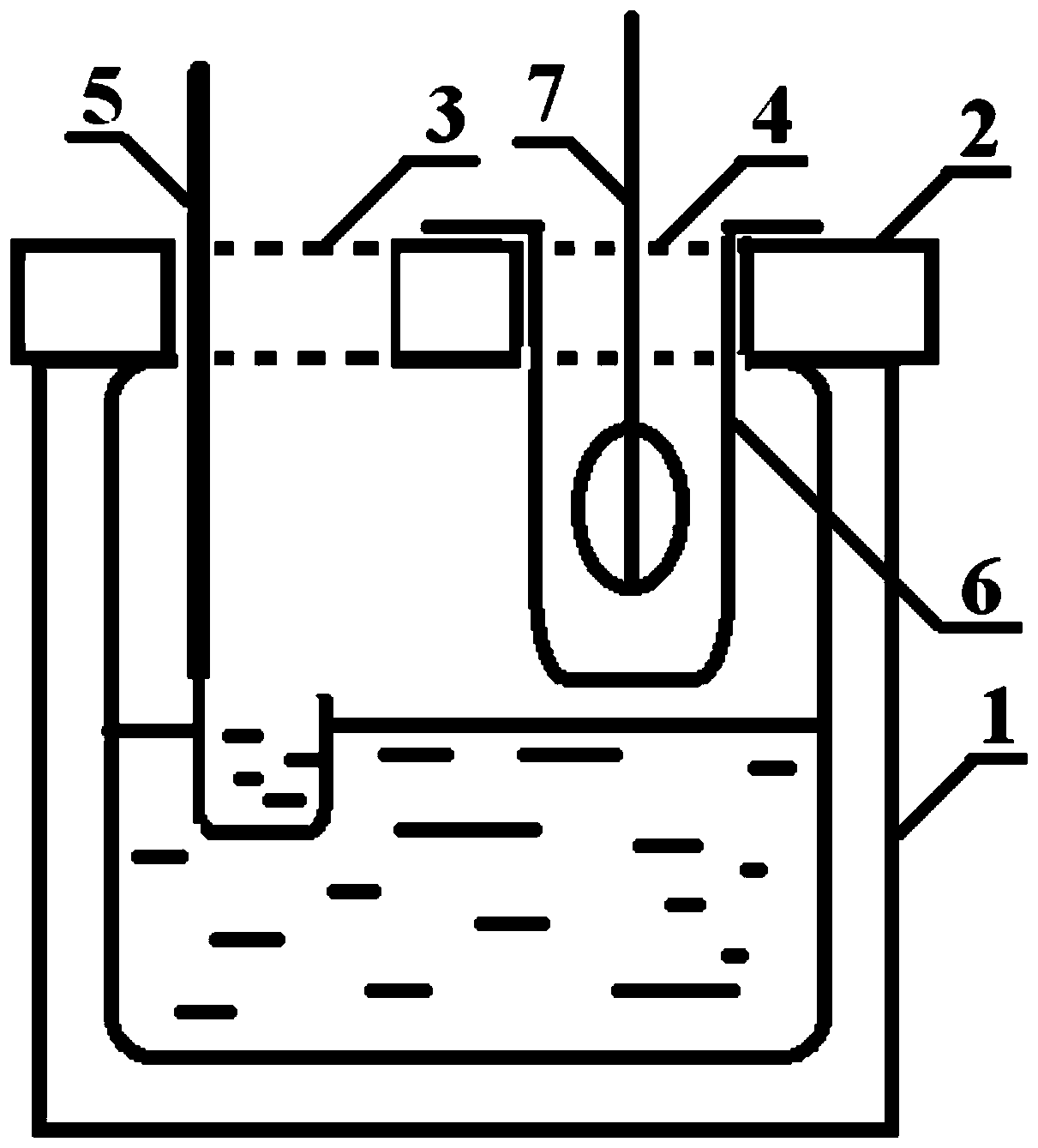

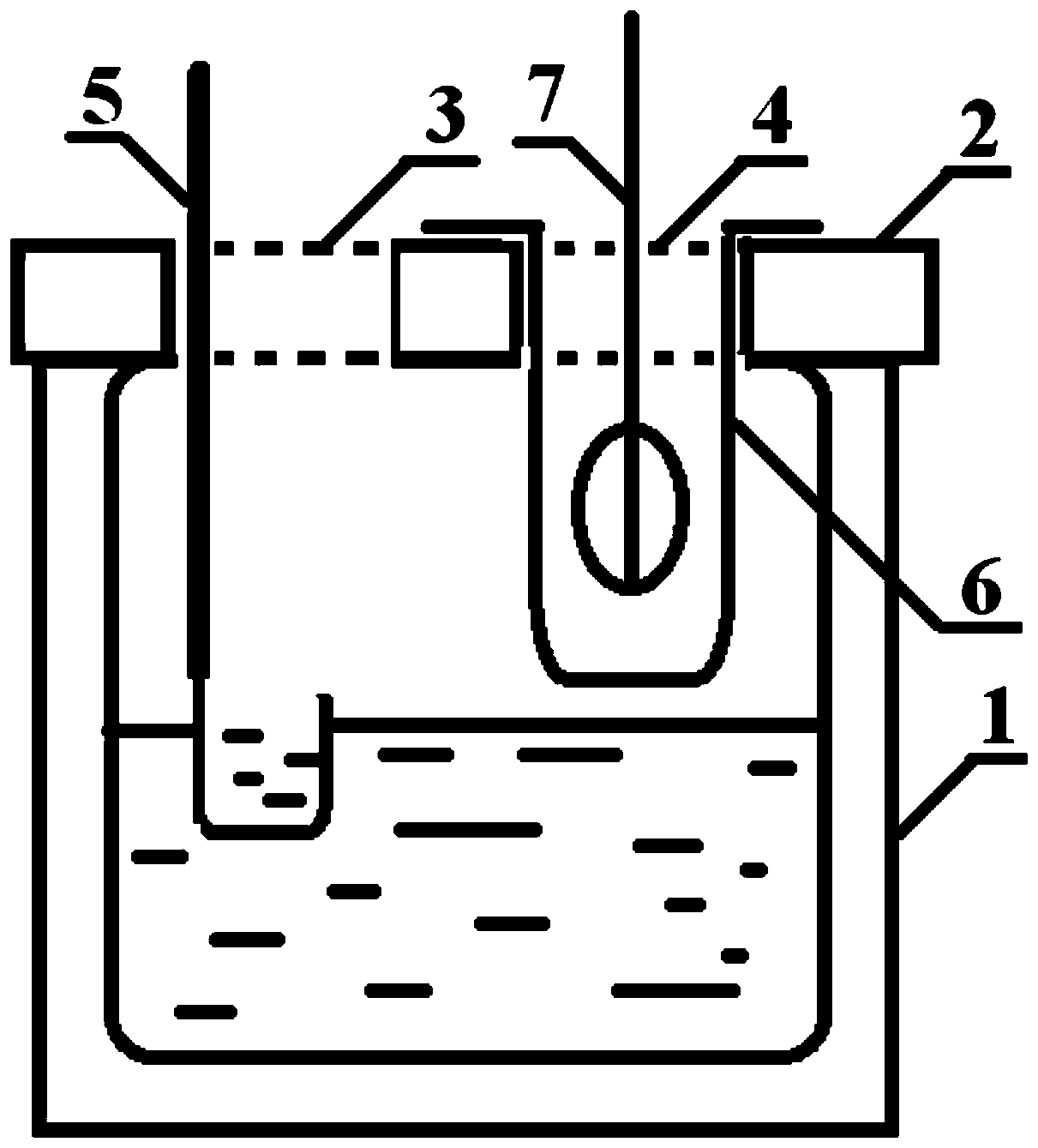

Foaming device and method for a porous magnesium alloy

A foaming device and porous magnesium technology, applied in the field of preparation of porous metal materials, can solve the problems of difficult control of the stirring process, low efficiency, poor formability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] The AZ31 magnesium alloy is heated and melted in a melting furnace, using CO 2 +SF 6 Mixed gas protection, heat preservation at 710°C, then put the foaming mold (thin-walled stainless steel mold) into the melting furnace through the second through hole for 20 minutes; then add 20g of 200 mesh magnesite powder to the foaming mold, Then use the pipette spoon to add 1kg of AZ31 magnesium alloy liquid in the melting furnace to the foaming mold through the first through hole. After stirring for 25s at 800r / min, lift the stirrer and take the foaming mold out of the melting furnace. After cooling, a porous magnesium alloy with an average pore diameter of 0.80 mm, a porosity of 60% and a uniform pore structure can be obtained.

Embodiment 2

[0056] The WE43 magnesium alloy is heated and melted in a melting furnace, using CO 2 +SF 6 Mixed gas protection, heat preservation at 720℃, then put the foaming mold (thin-walled stainless steel mold) into the melting furnace through the second through hole for 20 minutes; then add 15g of 200 mesh magnesite powder to the foaming mold, Then use the pipette spoon to add 1kg of the WE43 magnesium alloy liquid in the melting furnace to the foaming mold through the first through hole. After stirring at 550r / min for 20s, lift the stirrer and take the foaming mold out of the melting furnace. After cooling, a porous magnesium alloy with an average pore diameter of 0.80 mm, a porosity of 50% and a uniform pore structure can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com