A foamed aluminum sound-absorbing panel that can effectively reduce urban traffic noise and its preparation method

A technology for urban transportation and aluminum foam, which is applied in chemical instruments and methods, metal processing equipment, transportation and packaging, etc. Improve through-hole porosity, uniform through-hole pore size, and reduce urban traffic noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

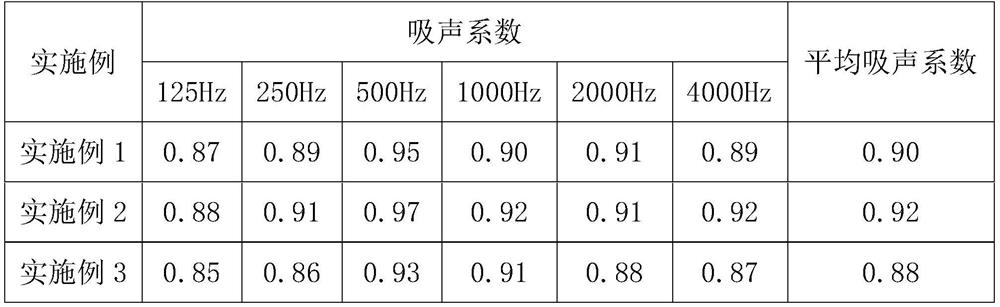

Embodiment 1

[0040](1) Add 35 parts by mass of aluminum chips to 35 parts by mass of absolute ethanol, mix and stir uniformly, soak for 20 minutes, and wash the filtered aluminum chips with 50 parts by mass of ultrapure water, and place them in a vacuum drying oven. After drying for 60 minutes at a temperature of 100°C, take it out, then add aluminum scraps to 35 parts by mass of absolute ethanol and soak for 40 minutes to obtain aluminum scrap alcohol solution;

[0041](2) Add the alcohol solution of aluminum chips obtained in step (1) to 60 parts by mass of deionized water at a stirring speed of 300r / min, stir at room temperature for 10 minutes, and then add 12 parts by mass of dispersant, namely coke 1 part of sodium phosphate, 1 part of sodium metasilicate, 3 parts of sodium polyethylene glycol alkyl aryl ether sulfonate, 2 parts of polyvinylpyrrolidone, and 5 parts of polyethylene glycol. After fully stirring and mixing at room temperature, Using an ultrasonic frequency of 20kHz and an ultraso...

Embodiment 2

[0047](1) Add 40 parts by mass of aluminum chips to 50 parts by mass of absolute ethanol, mix and stir evenly, soak for 25 minutes, and wash the filtered aluminum chips with 75 parts by mass of ultrapure water, and place them in a vacuum drying oven. After drying for 70 minutes at a temperature of 105°C, take it out, then add aluminum scraps to 50 parts by mass of absolute ethanol and soak for 50 minutes to obtain aluminum scrap alcohol solution;

[0048](2) Add the alcohol solution of aluminum chips obtained in step (1) to 70 parts by mass of deionized water at a stirring speed of 320r / min, stir at room temperature for 10 minutes, and then add 17 parts by mass of dispersant, namely coke 2 parts of sodium phosphate, 2 parts of sodium metasilicate, 4 parts of sodium polyethylene glycol alkyl aryl ether sulfonate, 4 parts of polyvinylpyrrolidone, and 5 parts of polyethylene glycol. After fully stirring and mixing at room temperature, Using an ultrasonic frequency of 24kHz and an ultrason...

Embodiment 3

[0054](1) Add 50 parts by mass of aluminum chips to 50 parts by mass of absolute ethanol, mix and stir uniformly, soak for 30 minutes, and wash the filtered aluminum chips with 75 parts by mass of ultrapure water and place them in a vacuum drying oven. After drying for 80 minutes at a temperature of 110°C, take it out, then add aluminum scraps to 50 parts by mass of absolute ethanol and soak for 60 minutes to obtain aluminum scrap alcohol solution;

[0055](2) Add the alcohol solution of aluminum chips prepared in step (1) to 70 parts by mass of deionized water at a stirring speed of 350r / min, stir at room temperature for 10 minutes, and then add 22 parts by mass of dispersant, namely coke 3 parts of sodium phosphate, 3 parts of sodium metasilicate, 5 parts of sodium polyethylene glycol alkyl aryl ether sulfonate, 5 parts of polyvinylpyrrolidone, and 6 parts of polyethylene glycol. After fully stirring and mixing at room temperature, Using an ultrasonic frequency of 25kHz and an ultras...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com